Six-station rotary table device for processing rocker arm seat

A six-station, rocker arm seat technology, used in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of frequent pressing of fixed parts, unqualified products, low profits, etc., to ensure the positioning effect. And the effect of continuity, improving processing efficiency and reducing defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

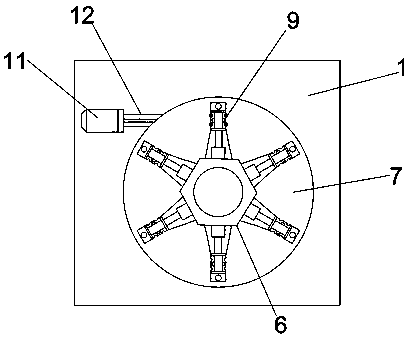

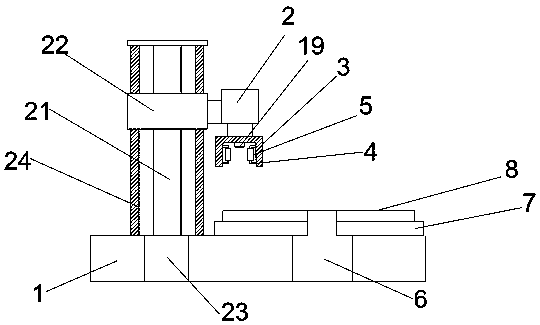

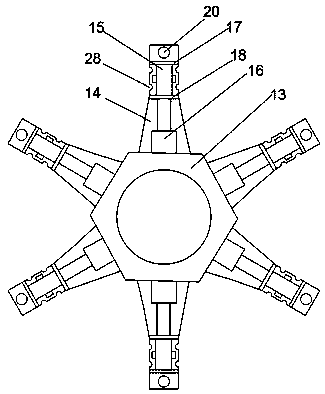

[0025] Such as figure 1 , Figure 3-5 As shown, a six-station turntable device for rocker arm base processing includes a fixed base 1, a lifting mechanism, a processing part and a positioning part located below the processing part. The processing part includes an upper rotating motor base 2, an upper rotating motor base 2 The bottom of the processing box 3 is connected with a processing box 3, the processing box 3 can be cylindrical or square, the opening of the processing box 3 is downward, the inner side of the processing box 3 is fixed with a bracket 4, and the bracket 4 is provided with a processing hob 5, which can The mechanism includes a sliding column 25 and a lifting beam 22. The lifting beam 22 is perpendicular to the sliding column 25 and the middle of the lifting beam 22 is penetrated by the sliding column 25. Both sides of the lifting beam 22 are provided with longitudinal hydraulic rods 26, and the hydraulic rods are placed On both sides of the sliding column 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com