Linkage type height adjusting device

A height adjustment device and height adjustment technology, applied in the direction of auxiliary devices, applications, auxiliary welding equipment, etc., can solve the problems of unstable precision, complicated operation, and occupation of production space, so as to improve production efficiency, avoid complicated operation, and improve the height position adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0036] Aiming at the problems that the existing manual welding takes up a lot of space and automatic welding cannot adjust the height to produce trusses of different specifications, the invention provides a linkage height adjustment device.

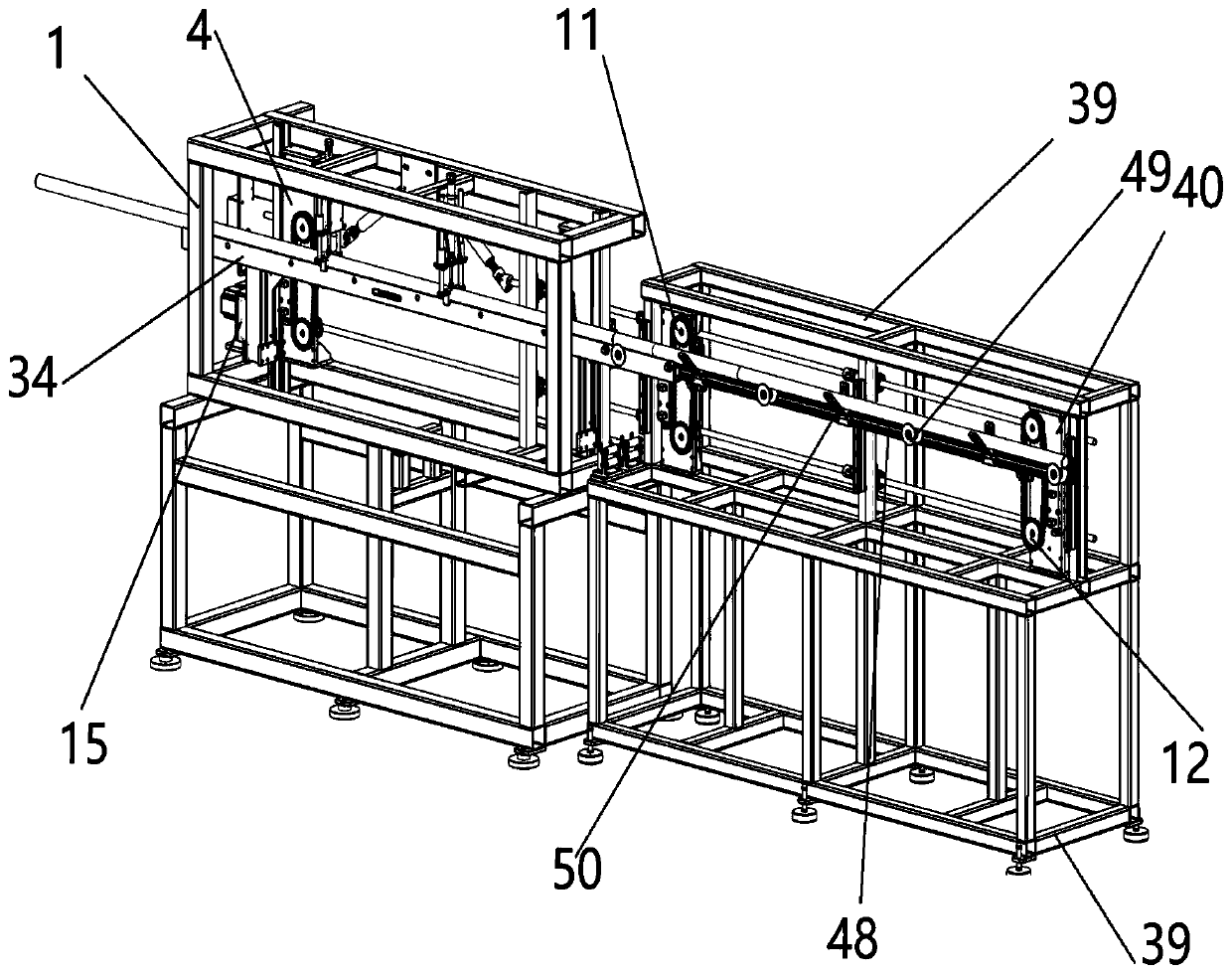

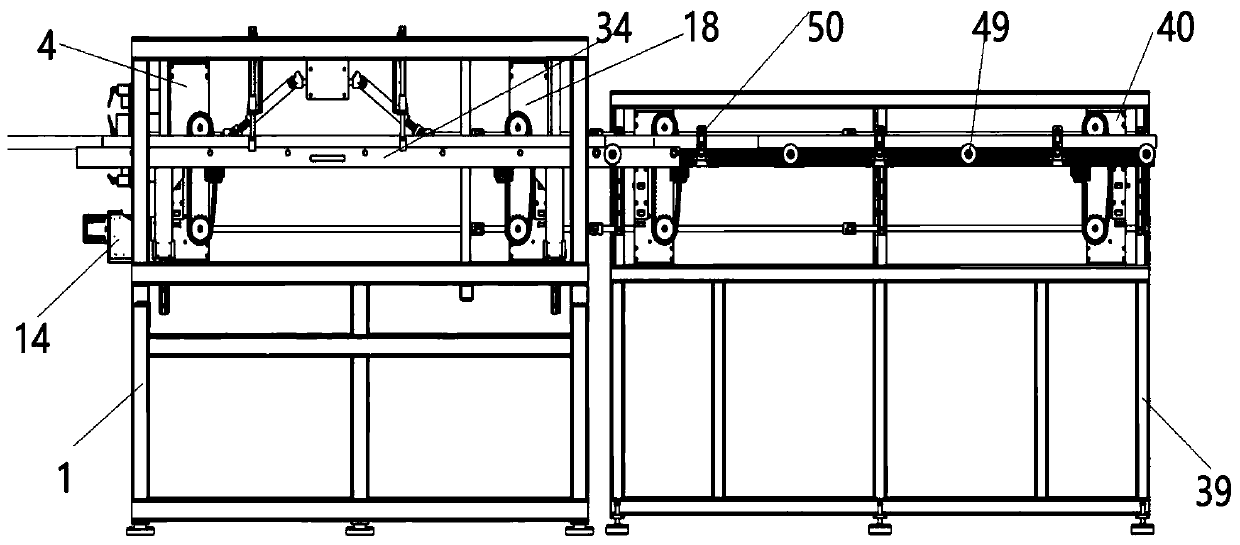

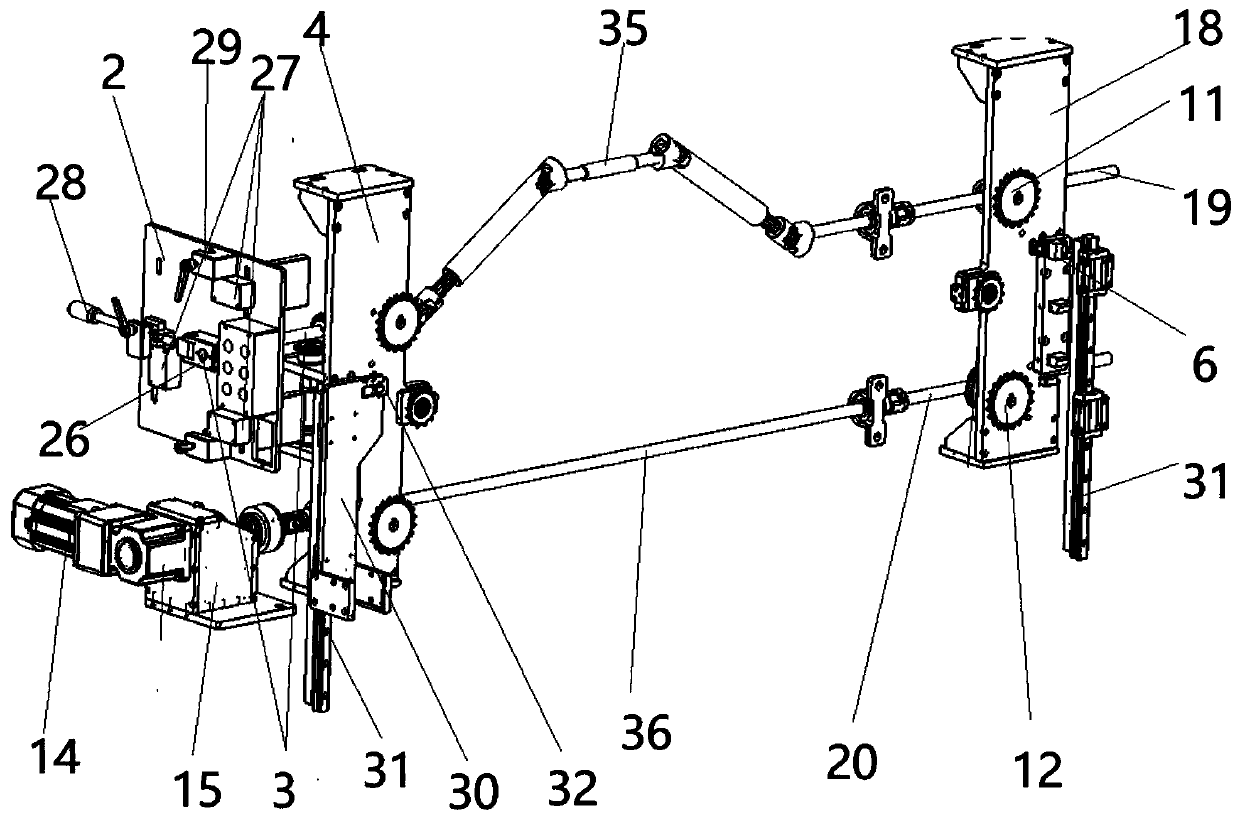

[0037] Such as Figure 1 to Figure 6 As shown, the embodiment of the present invention provides a linkage type height adjustment device, comprising: frame 1; 2 is provided with a height control mechanism, the height control plate is pierced with a height adjustment shaft 3; chain plate 4, the side of the end of the frame 1 of the chain plate 4, the back of the chain plate 4 is provided with a second A fixed deck and a second fixed deck, the height adjustment shaft 3 is set in the first fixed deck, the height adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com