A kind of cutting fluid purification method

A cutting fluid and liquid technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of incomplete filtration, secondary pollution, affecting filtration efficiency, etc., to ensure the use effect, prevent secondary pollution, Good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

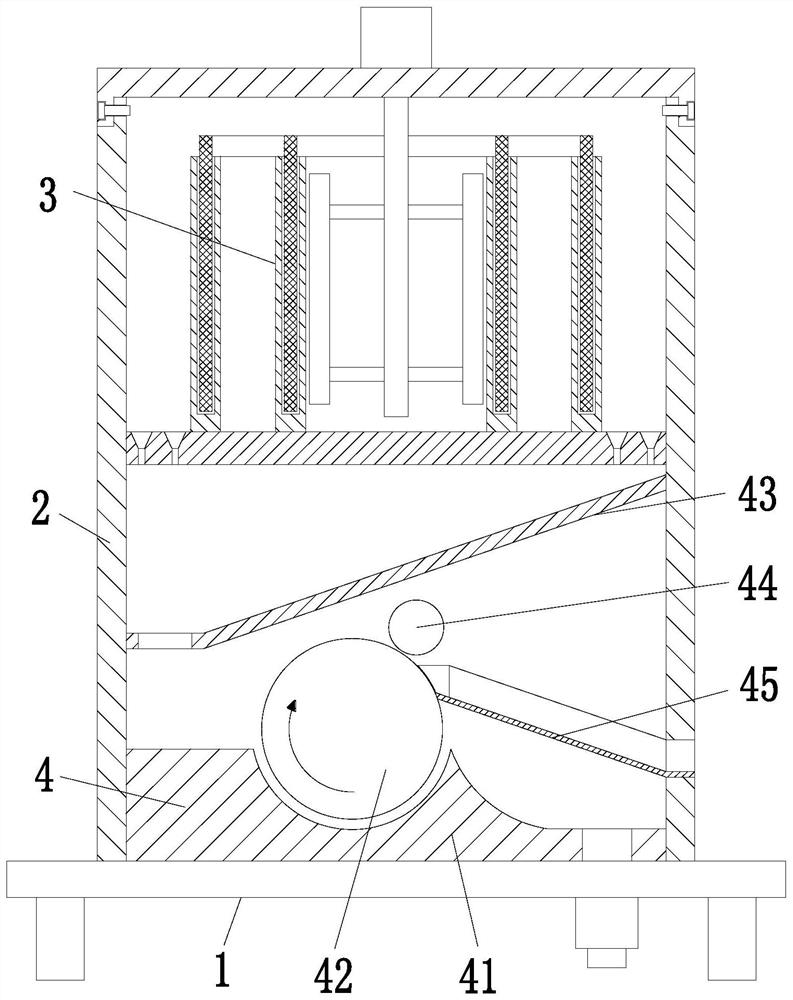

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

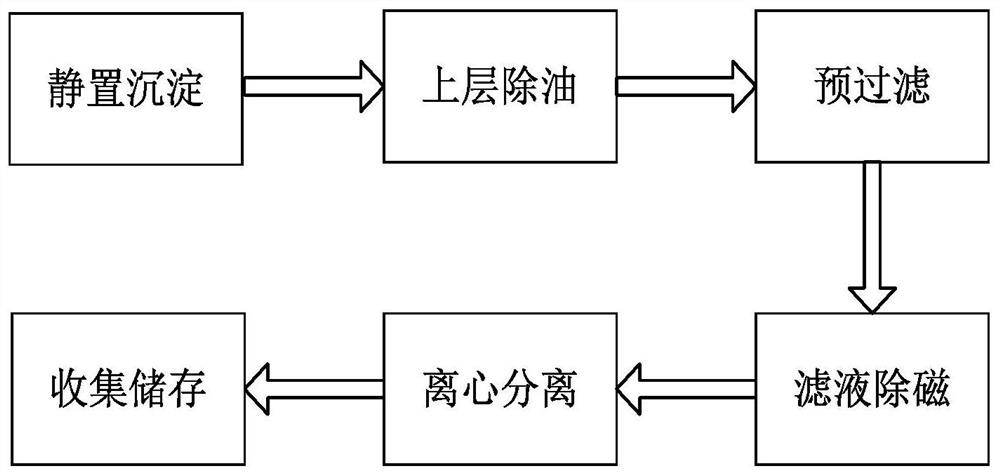

[0036] Such as Figure 1 to Figure 6 Shown, a kind of cutting fluid purification method comprises the following steps:

[0037] S1. Static precipitation: put the recovered cutting fluid into the collection bucket for static precipitation;

[0038] S2. Degreasing the upper layer: Manually remove impurities such as dirty oil and floating objects floating on the surface of the cutting fluid after standing in step S1;

[0039] S3. Pre-filtering: Pour the liquid degreased in step S2 into the filter device 3, and the filter device 3 can pre-filter larger particles of chips and particles inside the liquid;

[0040] S4, demagnetization of the filtrate: the filtrate after the pre-filtration in step S3 enters the inside of the demagnetization device 4, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com