Release agent brushing device for mold

A release agent and brushing technology, which is applied in the field of mold release agent brushing devices, can solve the problems of increased cost, increased labor intensity of staff, and low utilization rate of power equipment, so as to increase labor intensity and improve the use effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

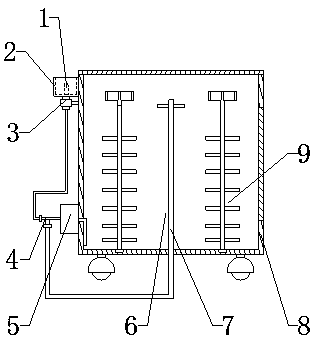

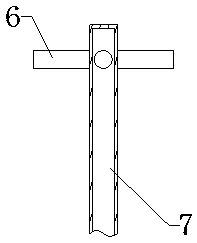

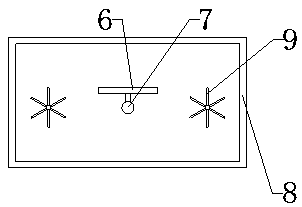

[0020] Specific implementation method: when in use, the staff first opens the cover plate, then adds the release agent raw material and water to the inside of the box body 8 according to a certain ratio, then the staff closes the cover plate, then starts the switch valve 2, and turns the self-priming pump 5 Connect with the external power supply through the wire, and then start the self-priming pump 5 through the control button, the internal motor of the self-priming pump 5 starts, and drives the impeller to rotate, thereby generating suction. into the connecting pipe, then through the self-priming pump 5 into the delivery pipe 4, then from the delivery pipe 4 into the return pipe 7, and from the return pipe 7 into the liquid outlet pipe 6, and from the liquid outlet pipe 6 Sprayed out, the sprayed mixture collides with the rear side edge of the rotating blade in the agitator 9, thereby driving the rotating blade and the rotating shaft to rotate, while the rotating blade rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com