Mist catcher capable of being conveniently cleaned

A fog catcher and convenient technology, applied in the field of fog catchers, can solve the problems of low height of the fog catcher, short time flowing through the fog catcher, incomplete filtration, etc., and achieve the effect of high efficiency and good filtering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

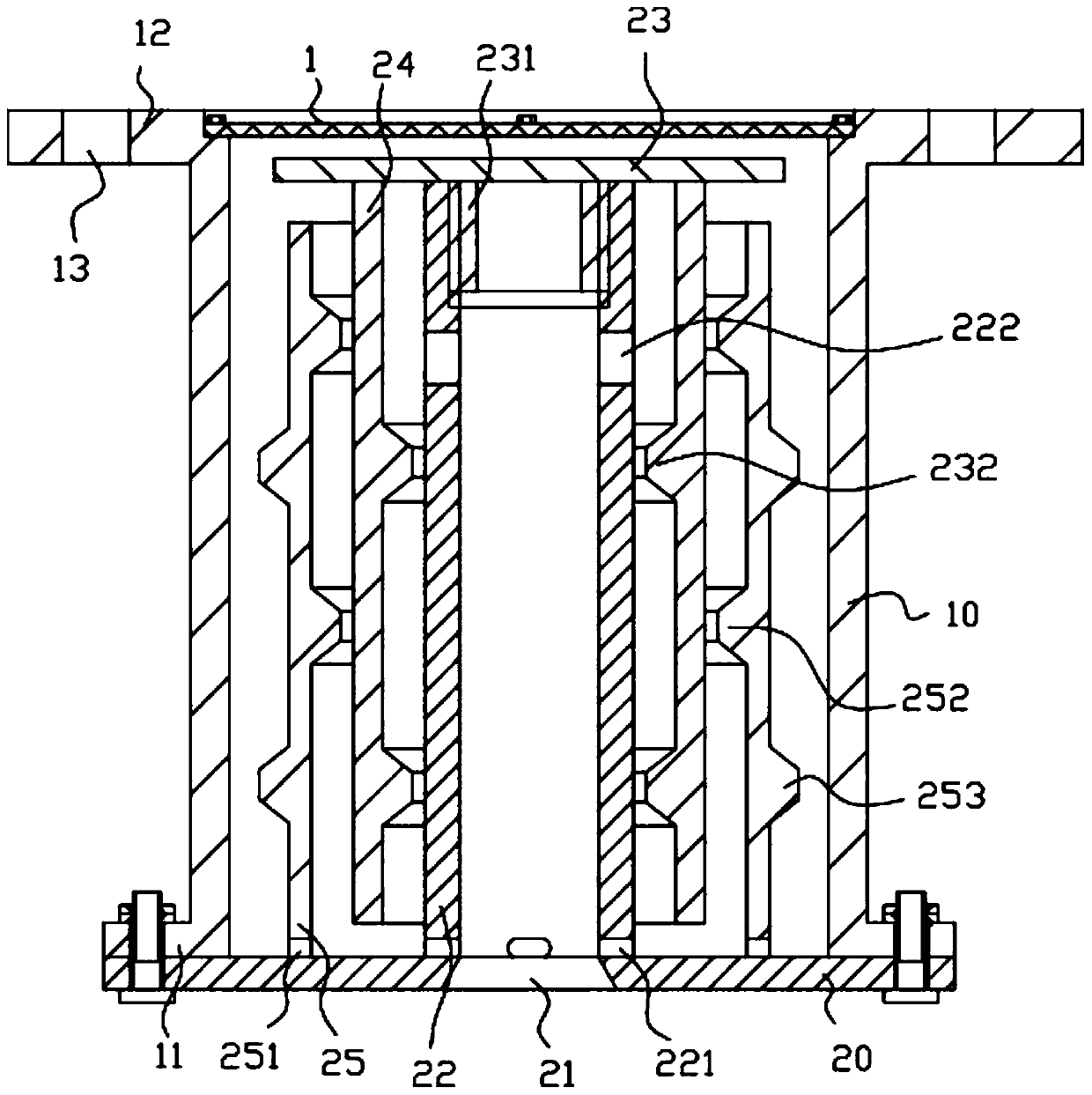

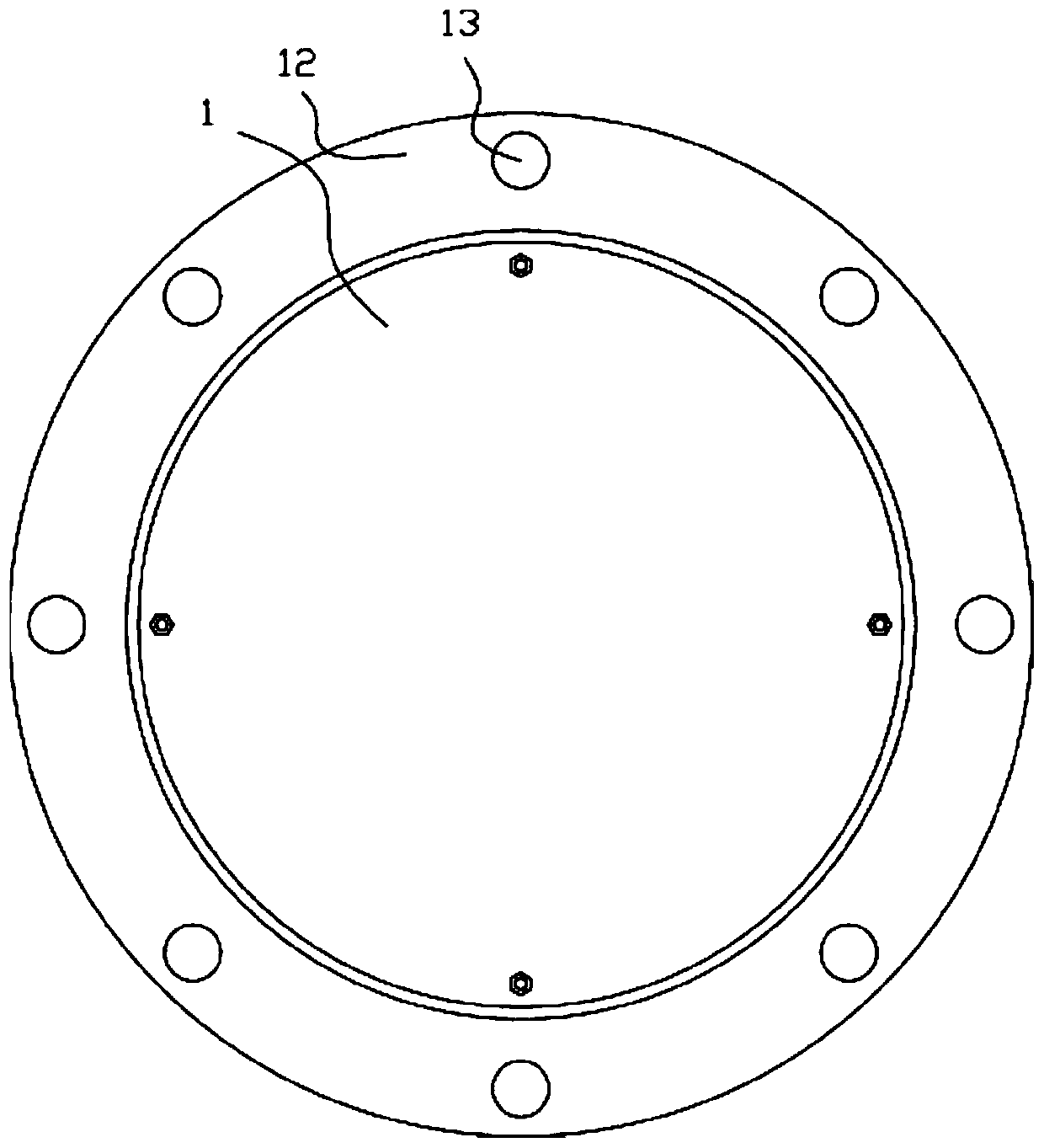

[0022] Example: see Figure 1 to Figure 2 As shown, a mist catcher that is easy to clean includes a filter sleeve 10, the bottom end of the filter sleeve 10 is fixed with a bottom connection plate 20, and the middle part of the bottom connection plate 20 is formed with an air intake through hole 21, and the bottom connection The middle part of the top surface of the plate 20 is fixed with a vertical guide sleeve 22, the vertical guide sleeve 22 communicates with the air intake through hole 21, and the top of the vertical guide sleeve 22 is fixed with an upper cover plate 23, and the upper cover plate 23 covers the vertical The top of the straight guide sleeve 22, the upper cover body 24 is fixed on the side bottom surface of the upper cover plate 23, the vertical guide sleeve 22 is inserted and sleeved in the upper cover body 24, and the top surface side of the bottom connecting plate 20 is fixed with an overcoat body 25, the upper sleeve body 24 is inserted and sleeved in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com