Gas turbine engine rotor disc holding assembly

A technology for gas turbines and rotor disks, applied to engine components, machines/engines, engine manufacturing, etc., can solve problems such as increasing the failure of rotor disks 99, unpopular arch deformation, and reducing the life of rotor disks 99

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]The above-mentioned and other features of the present technology are described in detail below. The various embodiments are described with reference to the drawings, wherein like reference numerals are used to refer to like elements throughout. In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of one or more embodiments. It may be noted that the illustrated embodiments are intended to illustrate rather than limit the invention. It is evident that such embodiments may be practiced without these specific details.

[0030] It can be noted that in the present disclosure, terms such as "first" and "second" are used here only to facilitate discussion, and do not have a specific time or sequential meaning unless otherwise indicated.

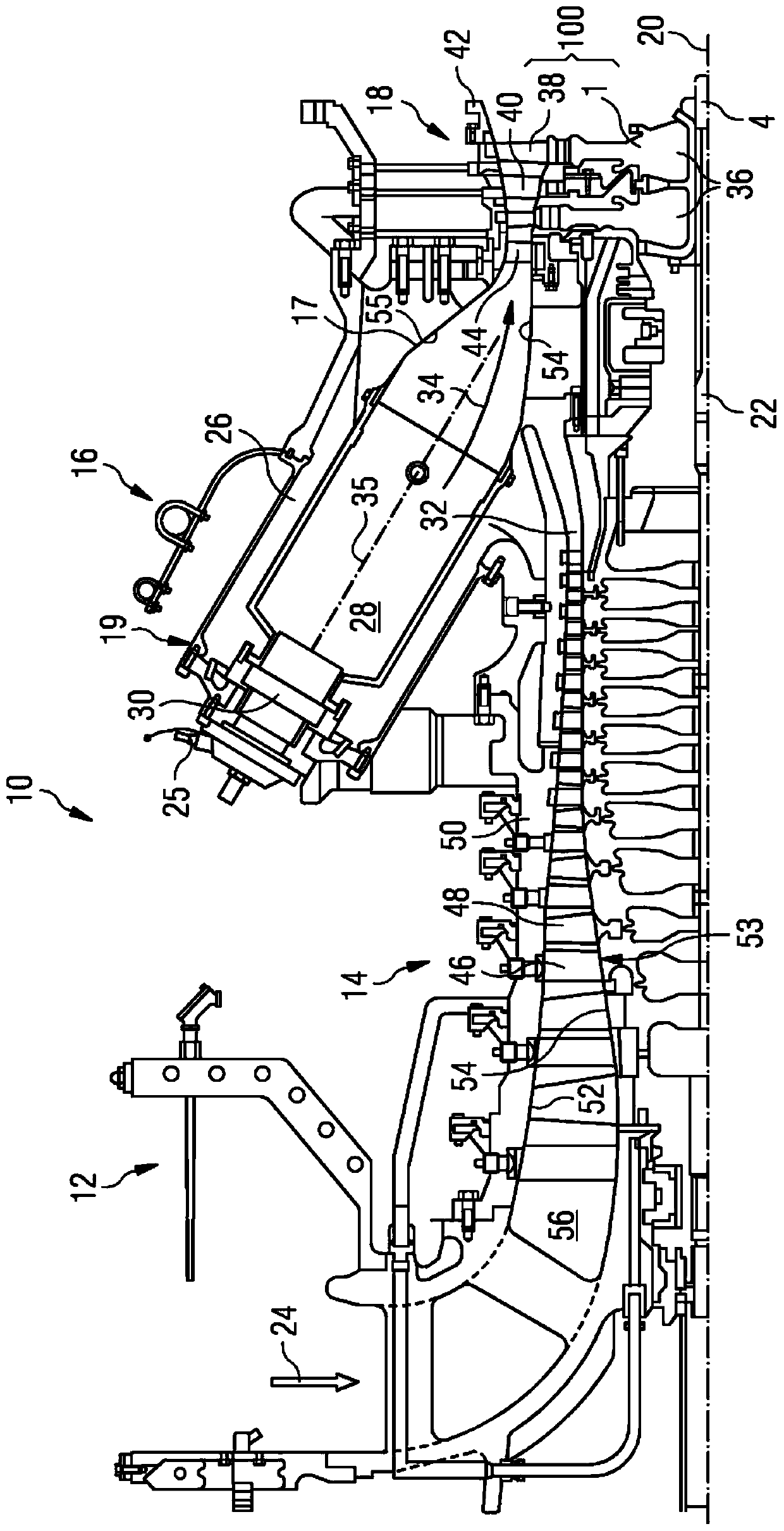

[0031] figure 1 An example of a gas turbine engine 10 is shown in cross-section. Gas turbine engine 10 includes, in flow series, an intake 12, a com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com