Single-pole single-suction submerged pump

A submerged pump and unipolar technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of high manufacturing cost, poor anti-resonance, high requirements, etc., and achieve low production cost, long service life and good sealing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

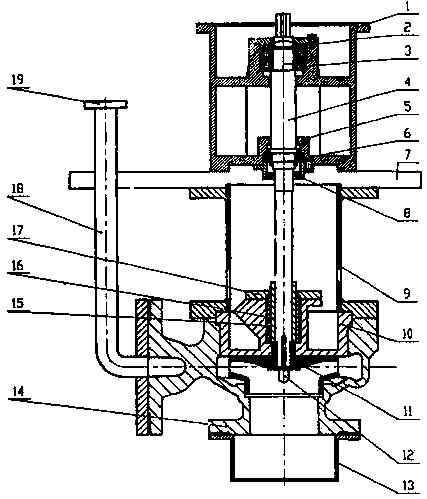

[0011] A single-pole single-suction submersible pump. The submersible pump includes a pump frame 1, a fixing nut 2, an upper bearing 3, a motor output shaft 4, a lubrication hole 5, a lower bearing 6, a base 7, an oil seal 8, and a support tube 9. Pump cover 10, impeller 11, impeller nut 12, filter screen 13, pump body 14, lower sheath 15, shaft sleeve 16, sheath end cover 17, outlet pipe 18 and flange 19;

[0012] The pump frame 1 is arranged on the base 7, the fixing nut 2, the upper bearing 3, the motor output shaft 4, and the lubricating hole 5 are respectively arranged in the pump frame 1, and the upper bearing of the motor output shaft 4 is arranged 3 and fixed by a fixing nut 2, the lubrication hole 5 is arranged at the lower end of the motor output shaft 4,

[0013] The lower part of the motor output shaft 4 is connected to the pump shaft, the joint of the motor output shaft 4 and the pump shaft is provided with an oil seal 8, the support pipe 9 is connected to the lower pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com