Braking and retarding integration supporting bridge for trailer

A support bridge, integrated technology, applied in the direction of brakes, brake components, brake types, etc., can solve the problems of low degree of integration, difficult installation position of retarder, increased cost, etc., achieve enhanced effect, realize normal circulation and energy The conversion, the effect of reducing the quality of the whole bridge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings. The examples given are only for explaining the present invention, not for limiting the scope of the present invention.

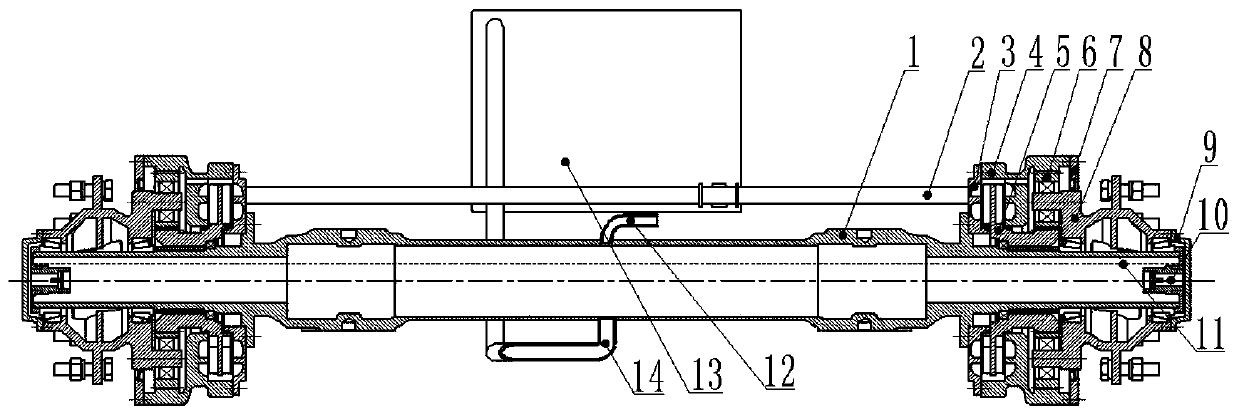

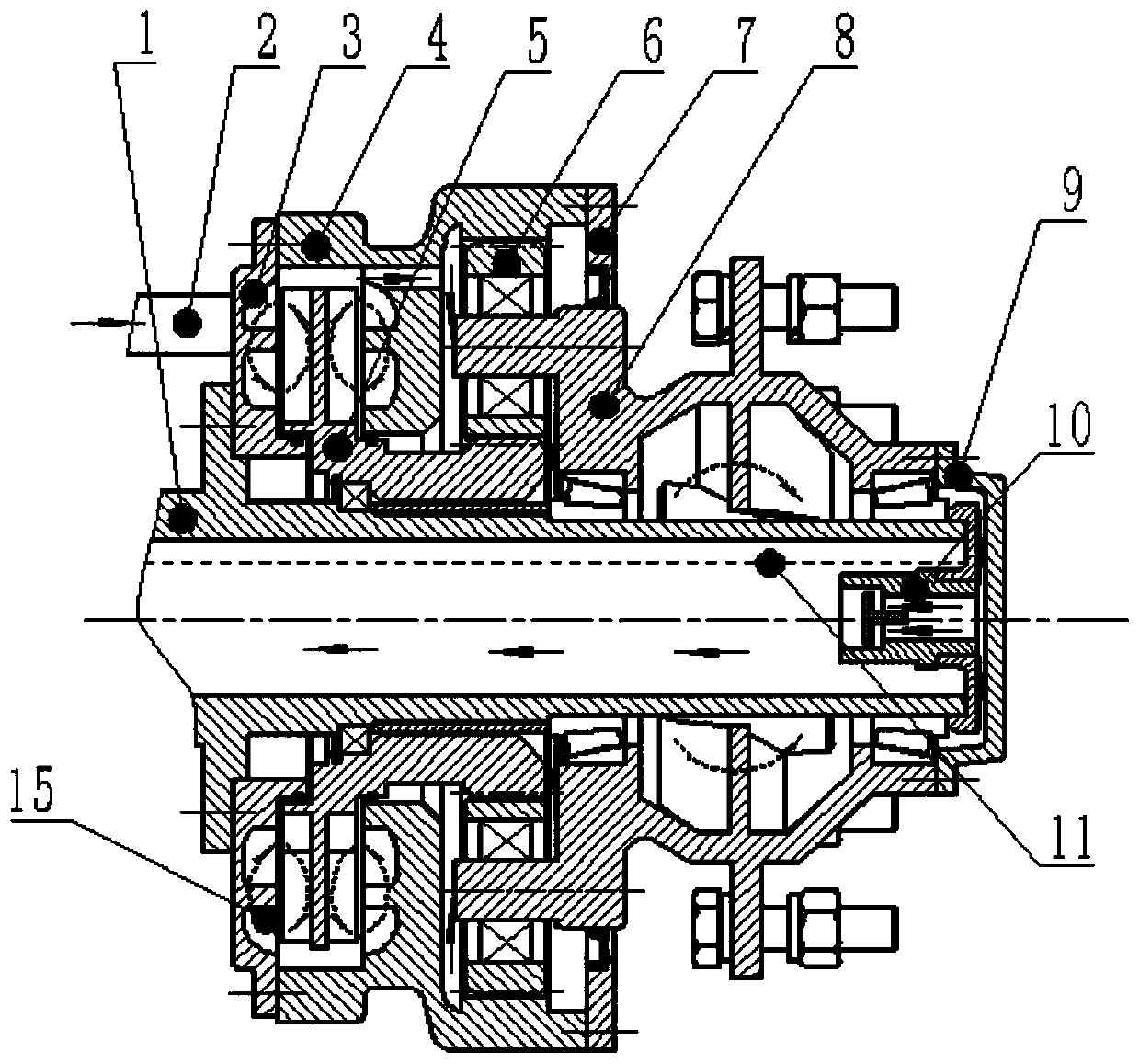

[0027] Such as figure 1 As shown, it is an assembly diagram of a braking and retarding integrated support bridge for a trailer of the present invention, including a support bridge part, a hydraulic retarder part, a speed increasing mechanism part, a heat dissipation circulation system and a control module.

[0028] The supporting bridge part includes a supporting axle housing 1 , a wheel hub 8 and an end cover 9 ;

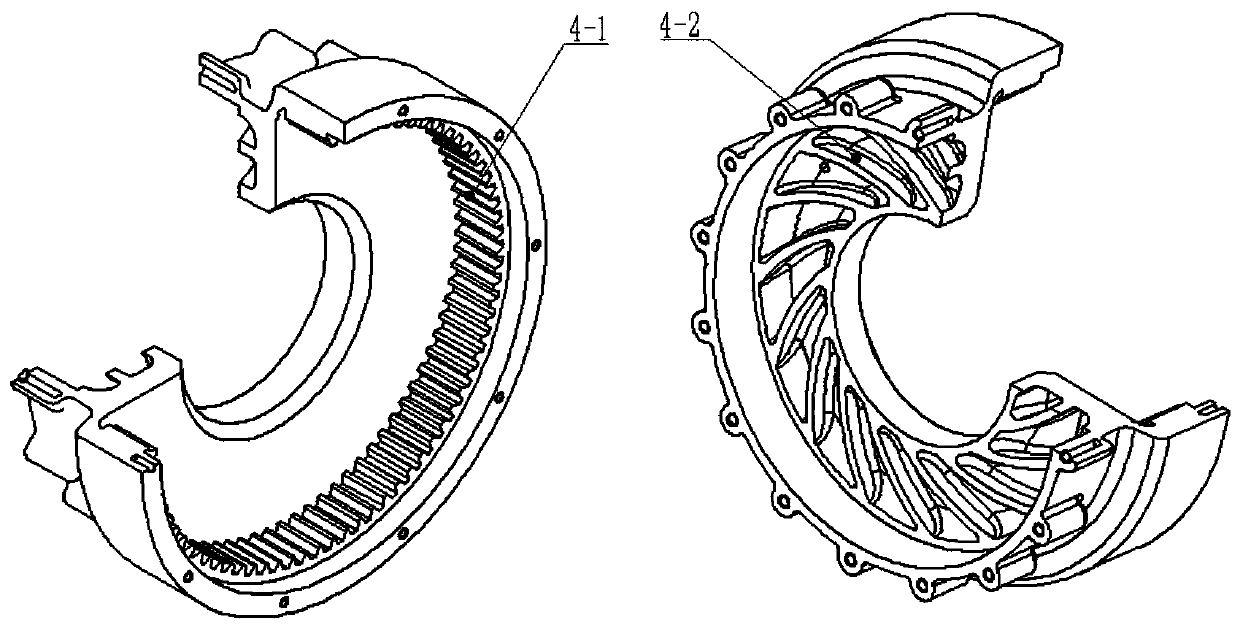

[0029] The hydraulic retarder part includes the left stator impeller 3, the right stator impeller 4-2 and the rotor impeller 5-2, the left stator impeller 3, the right stator impeller 4-2 and the rotor impeller 5-2 are blade structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com