Multifunctional printer

A printer and multi-functional technology, applied in typewriters, printing devices, printing, etc., can solve problems such as difficulty in special-shaped design, increased mold costs, and increased volume, achieving flexible and changeable position design, saving production costs, and reducing management costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

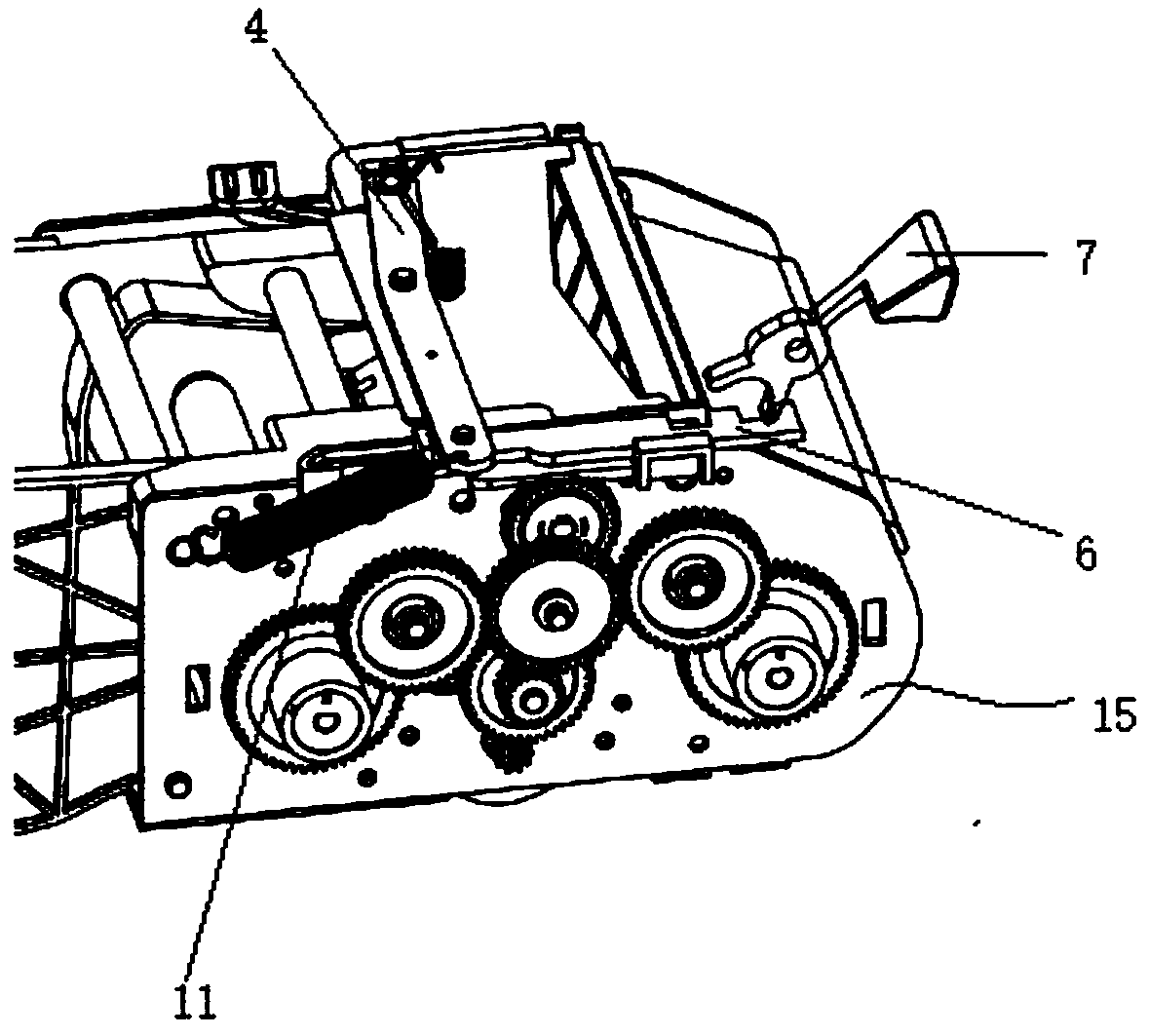

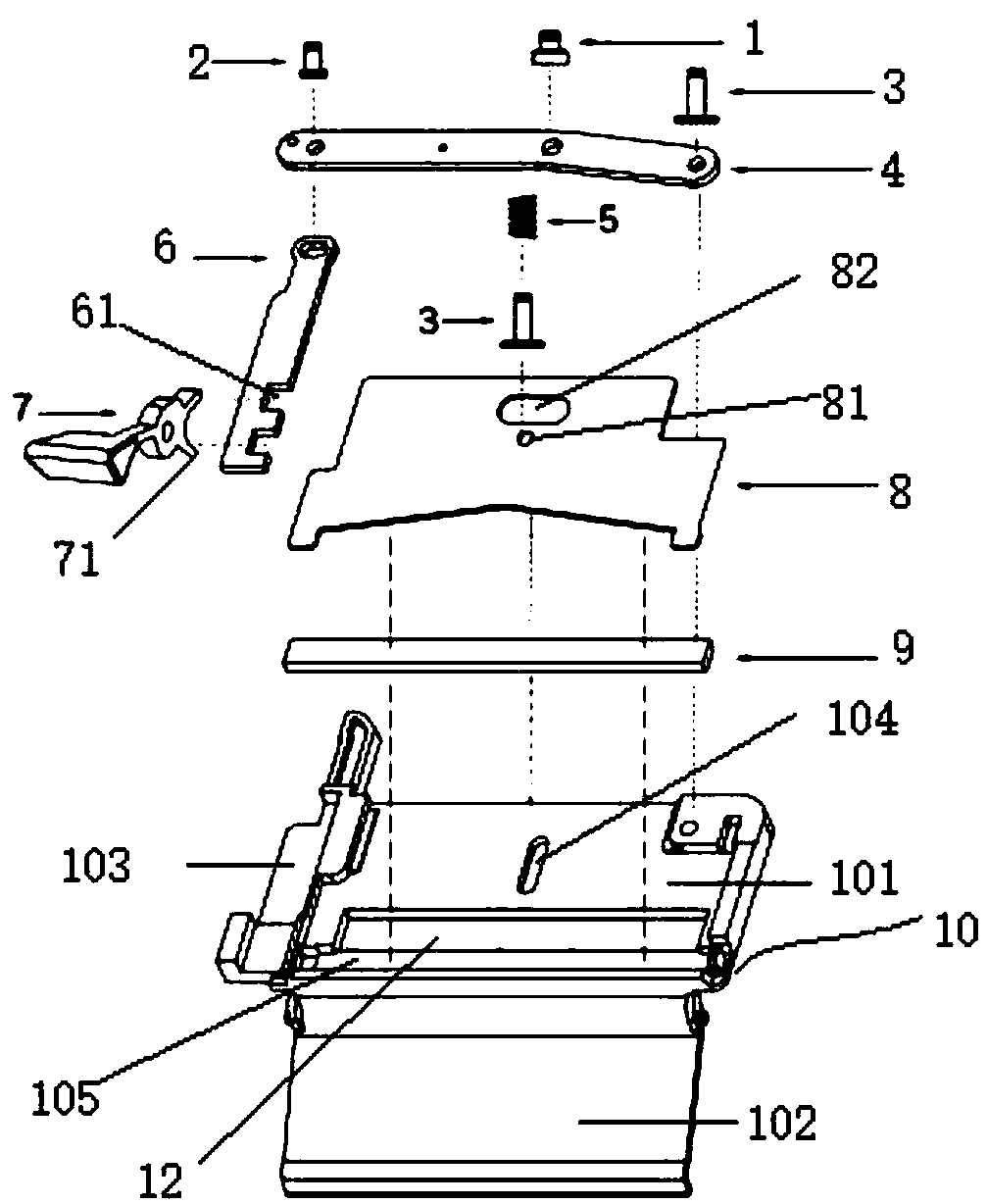

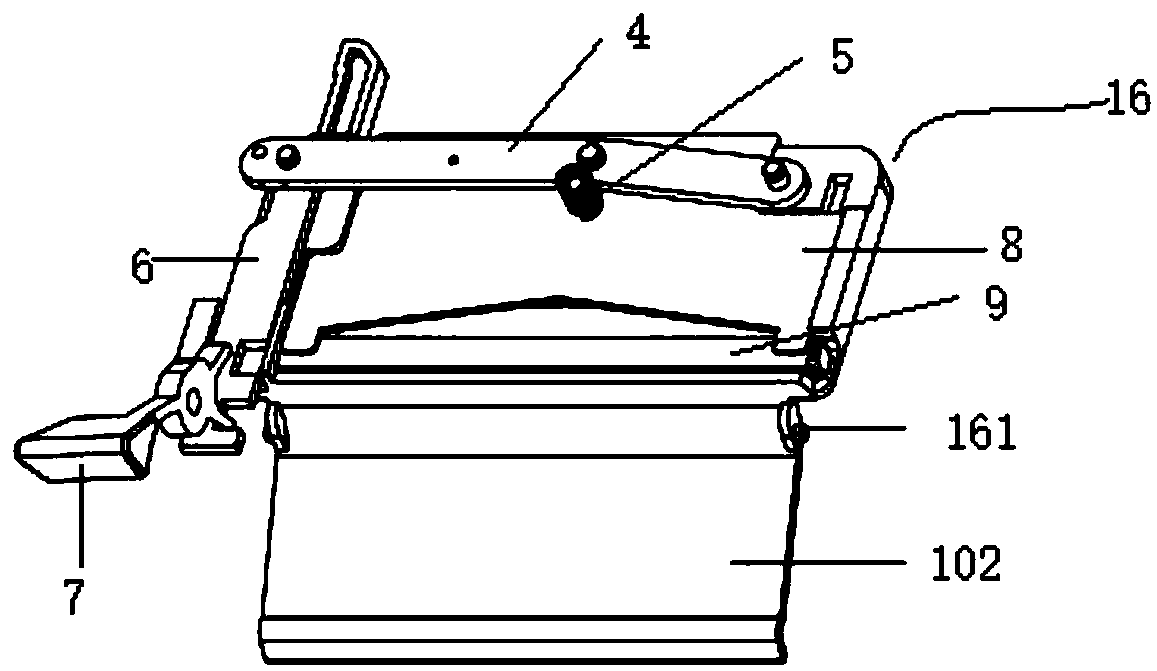

[0025] Such as figure 2 , image 3 As shown, the multifunctional printer of the present invention includes a casing (not shown), a cutter device 16 and an inner frame 15 . Described cutter device 16 comprises cutting knife 8, fixed knife 9, knife rest 10 and driving device, and described driving device drives cutting knife to move back and forth relative to fixed knife, and described knife rest 10 is fixed at the front end of inner frame 15, and described fixed knife Knife 9 is fixed on the knife rest 10.

[0026] In a specific embodiment, the drive device includes a cutter bar 4 and a cutter bar 6, the cutter bar 4 is movably connected to the knife holder 10, and the cutter bar 4 is pivotally connected to the cutter bar 6 , the cutter pull bar and the cutter press rod drive the cutter to move back and forth relative to the fixed knife.

[0027] One end of the cutter bar 4 is fixed on the knife holder 10 through the cutter shaft 3, the other end of the cutter bar 4 is pivo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com