An impeller installation tool

A technology for installing tools and impellers, which is applied in the direction of manufacturing tools and hand-held tools, can solve the problems of parts damage and poor safety, and achieve the effects of good safety, easy disassembly and assembly, and simple positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

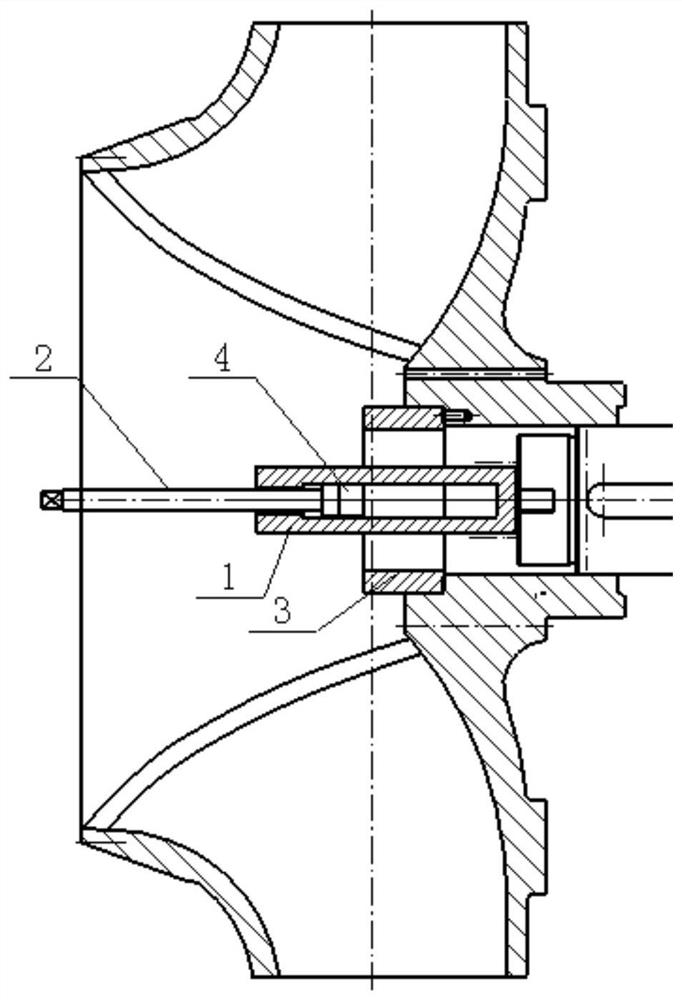

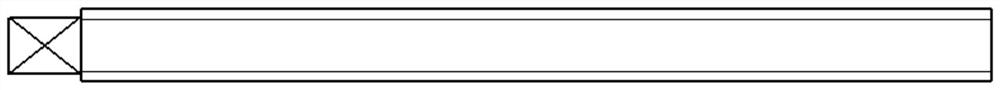

[0024] Such as figure 1 As shown, the structure diagram of the use state of the impeller installation tool; the impeller installation tool includes a fixed sleeve 1, a screw 2, a transition sleeve 3 and a top block 4;

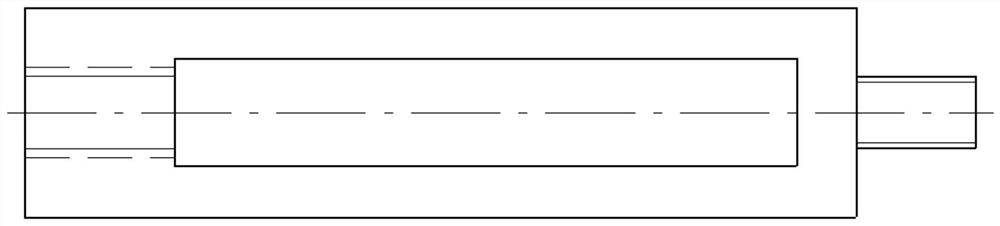

[0025] figure 2 It is a structural diagram of the fixing sleeve, the fixing sleeve 1 is a cylindrical member with an open end, the inner wall of the mouth of the opening end of the cylindrical member is processed with internal threads, and the closed end surface of the cylindrical member is A connecting head with external thread is arranged in the center, and the external thread of the connecting head matches the internal thread of the threaded hole at the front end of the pump shaft; the side wall of the cylindrical member is symmetrically opened with axially extending long guide holes ;

[0026] The transition sleeve 3 is a cylindrical piece with openings at both ends. The inner diameter of the transition sleeve 3 is larger than the outer diameter of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com