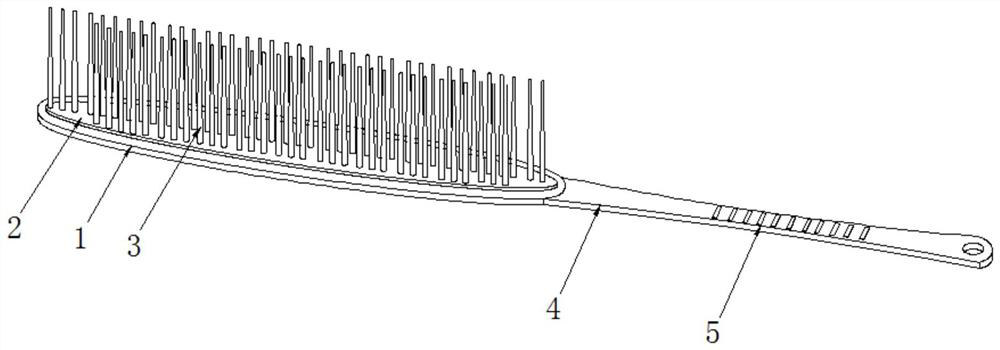

A kind of air-cushion comb with silver comb and its preparation process

A preparation process and air cushion technology, applied in hair combs, hairdressing equipment, devices for washing hair or scalp, etc., can solve the problems of poor strength, short service life, easy breakage of comb handles, etc., and achieve soft and shiny hair. The effect of preventing hair malnutrition and promoting blood circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

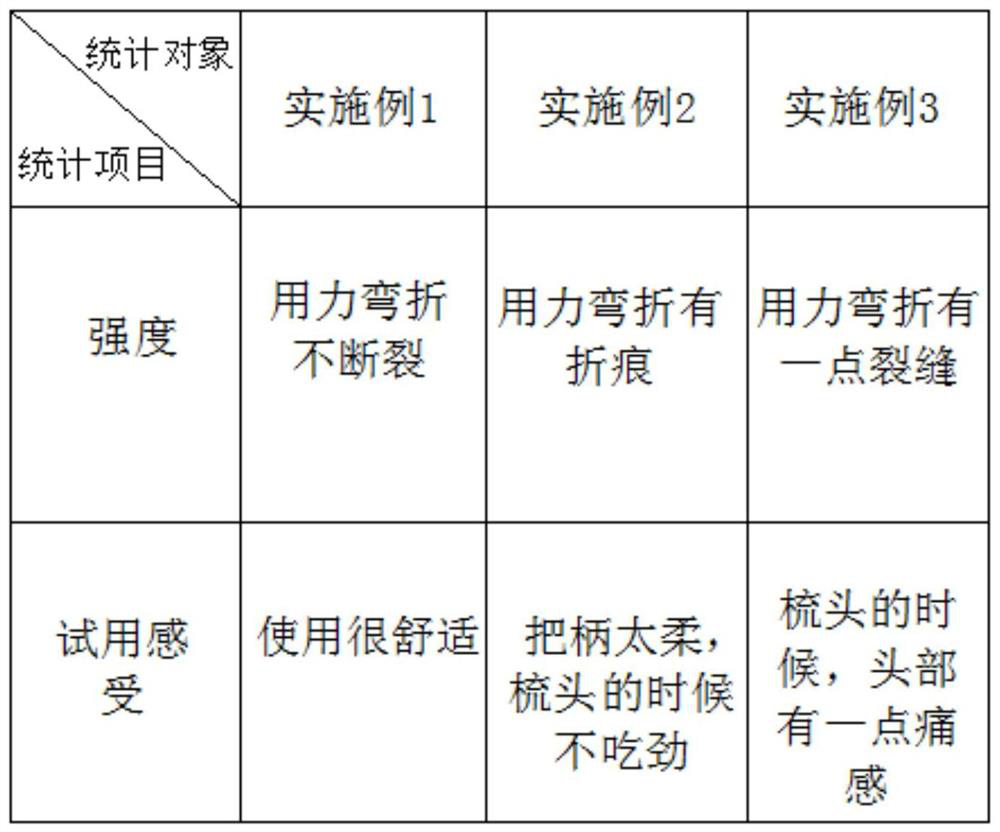

Embodiment 1

[0035] S1. Select 32 parts of polyurethane, 32 parts of phenolic resin and 23 parts of silane coupling agent, put the selected 32 parts of polyurethane, 32 parts of phenolic resin and 23 parts of silane coupling agent into the reactor, and adjust the temperature of the reactor to 44°C , the stirring speed is 2500r / min, and the reaction time is 17 minutes;

[0036] S2, then 20 parts of antioxidant, 15 parts of foaming agent and 20 parts of compatibilizer, pour 20 parts of antioxidant, 15 parts of foaming agent and 20 parts of compatibilizer into the mixture in step S1, Mix and stir again, the temperature of the reactor is 40°C, the stirring speed is 2250r / min, and the reaction time is 30 minutes. After all the raw materials are melted, pour them into the mixer while they are hot, start the mixer, and the mixer mixes the melted raw materials. The stirring rate is 320 rpm, and the stirring time is 1.5 hours;

[0037] S3, put the mixture prepared in S2 into a stirring tank for st...

Embodiment 2

[0040] S1. Select 25 parts of polyurethane, 25 parts of phenolic resin and 15 parts of silane coupling agent, put the selected 25 parts of polyurethane, 25 parts of phenolic resin and 15 parts of silane coupling agent into the reactor, and adjust the temperature of the reactor to 42°C , the stirring speed is 2400r / min, and the reaction time is 15 minutes;

[0041] S2, then choose 12 parts of antioxidants, 8 parts of blowing agents and 18 parts of compatibilizers, pour 12 parts of antioxidants, 8 parts of blowing agents and 18 parts of compatibilizers into the mixture in step S1 , mix and stir again, the temperature of the reactor is 35°C, the stirring speed is 2000r / min, and the reaction time is 25 minutes. After all the raw materials are melted, pour them into the mixer while they are hot, start the mixer, and the mixer mixes and stirs the melted raw materials , the stirring rate is 250 rpm, and the stirring time is 1 hour;

[0042] S3, put the mixture prepared in S2 into a ...

Embodiment 3

[0045] S1. Select 40 parts of polyurethane, 40 parts of phenolic resin and 30 parts of silane coupling agent, put the selected 40 parts of polyurethane, 40 parts of phenolic resin and 30 parts of silane coupling agent into the reactor, and adjust the temperature of the reactor to 46°C , the stirring speed is 2600r / min, and the reaction time is 20 minutes;

[0046] S2, then choose 25 parts of antioxidants, 20 parts of blowing agents and 23 parts of compatibilizers, and pour 25 parts of antioxidants, 20 parts of blowing agents and 23 parts of compatibilizers into the mixture in step S1 , mix and stir again, the temperature of the reaction kettle is 45°C, the stirring speed is 2500r / min, and the reaction time is 35 minutes. After all the raw materials are melted, pour them into the mixer while they are hot, start the mixer, and the mixer mixes and stirs the melted raw materials , the stirring rate is 400 rpm, and the stirring time is 2 hours;

[0047] S3, put the mixture prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com