A petal -shaped nanofiber production device and method

A nanofiber and production device technology, applied in fiber processing, textile and papermaking, electrospinning, etc., can solve the problems of poor electrospinning production continuity, difficult to control nanofiber size, unstable continuous production, etc., to improve production. Continuity, increase the number of excitations, and ensure the effect of production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

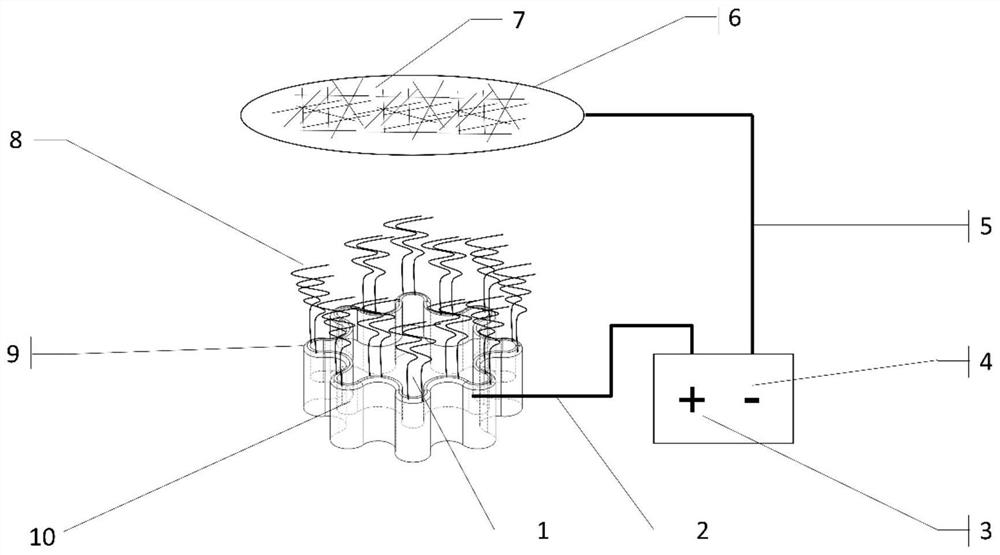

[0033] A petal-shaped nanofiber production device comprising:

[0034] A petal-shaped spinning nozzle 10 for spraying the spinning solution into a spinning jet 8;

[0035] A high-voltage spinning power supply for making the petal-shaped spinning nozzle 10 generate static electricity;

[0036] A nanofiber collecting device 6 for collecting the spinning jet 8 ejected from the petal-shaped spinning nozzle 10 .

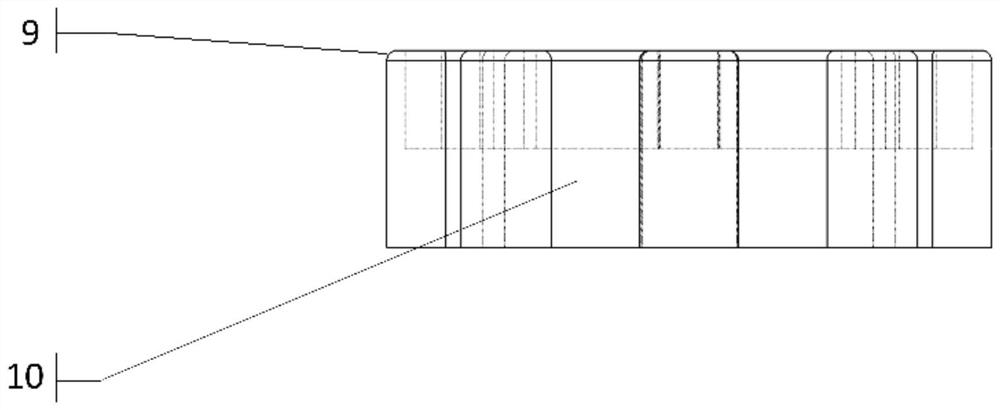

[0037] The petal-shaped spinneret 10 is a cylinder with a petal-shaped cross section, the lower part is a solid part, and the upper part is a hollow part 1 for containing the spinning solution. The wall thickness of the hollow part 1 is 0.1-2 mm, and the edge 9 of the hollow part 1 is provided with a rounded corner with a radius of 0.1-1 mm. The petals in the cross-section of the petal-shaped spinning nozzle 10 have the same curvature, that is, the cross-section is formed by connecting multiple small circular arcs along the large circle, the adjacent small circular arcs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com