Formula and preparation technology for domestic polypropylene fiber cement-based material

A polypropylene fiber and cement-based material technology, applied in the field of large-deformation cement-based composite materials, can solve problems such as reducing production efficiency and prolonging mixing time, and achieve the effects of preventing local agglomeration, prolonging mixing time, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

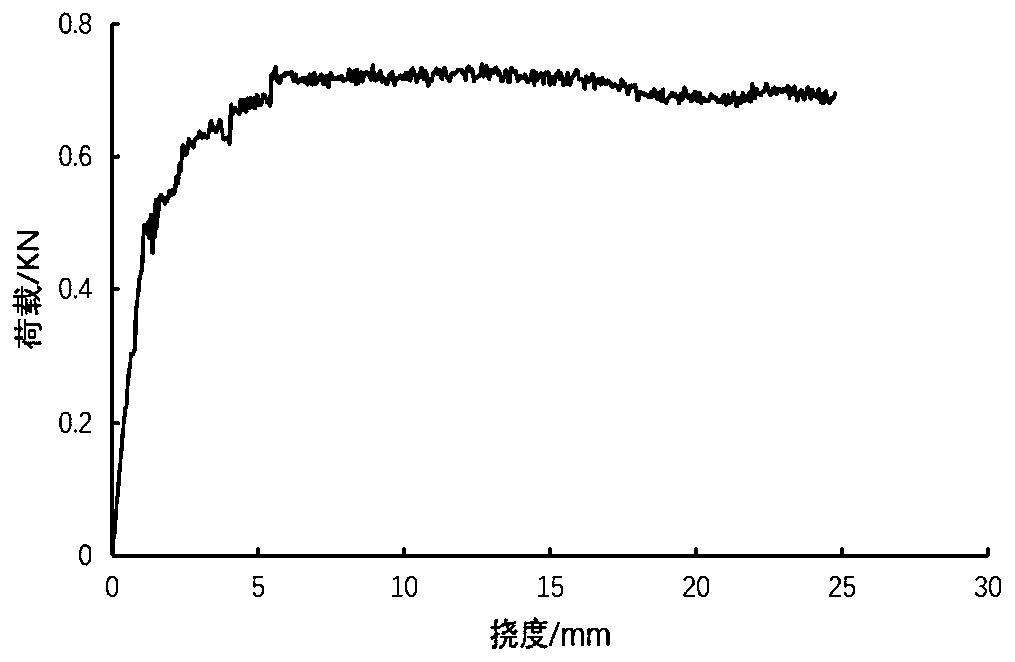

Embodiment 1

[0024] Take 670g cement and 450g fly ash and dry mix for 30s, add 280g water and stir quickly for 2min. Turn the mixer to slow speed, divide 13g fiber into the clean slurry in three times, then add 4g water reducing agent, and stir rapidly for 5 minutes. Set the mixer to slow speed, add 500g of fine sand to the mixture, then add 4g of water reducing agent and 20g of water, and stir rapidly for 5 minutes.

[0025] The mixed mixture is poured into a 15mm×100mm×400mm test mold for molding, demolded after 24 hours and put into a standard curing room for health preservation.

[0026] Cement: 42.5 grade ordinary Portland cement produced by a factory in Changchun is used.

[0027] Fly ash: First-class fly ash produced by a factory in Henan is used.

[0028] Sand grains: Ultra-fine river sand with a maximum grain size of 0.3 mm is used.

[0029] Fiber: Polypropylene monofilament fiber produced by a factory in Hubei, with a diameter of 38 μm and a length of 12 mm.

[0030] Water re...

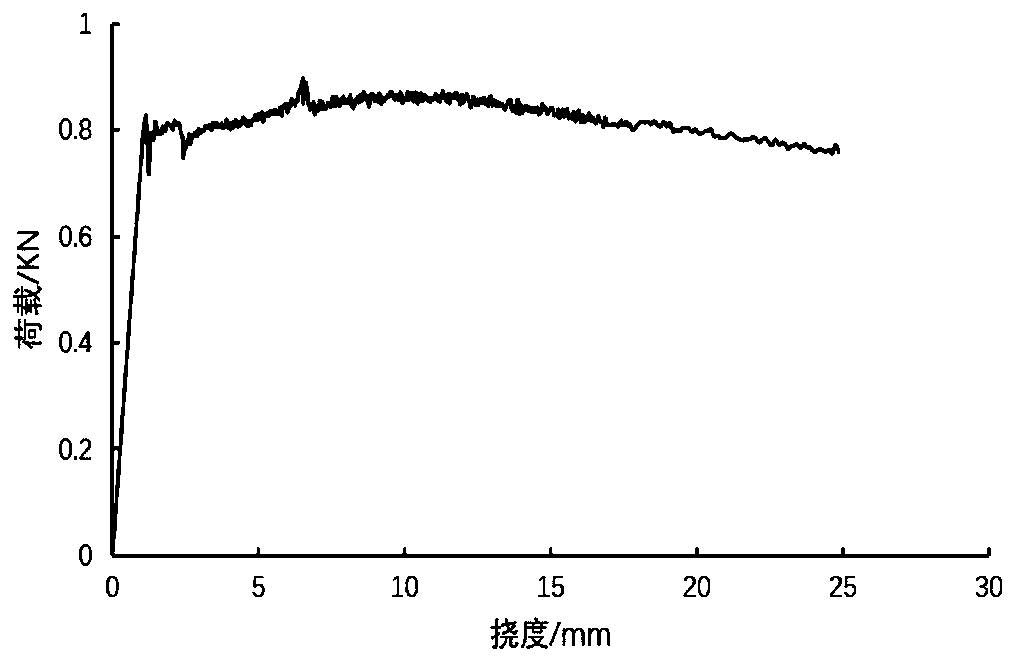

Embodiment 2

[0039]Take 560g of cement and 560g of fly ash and dry mix for 30s, add 280g of water and stir quickly for 2min. Turn the mixer to slow speed, divide 15g fiber into the clean slurry in three times, then add 4g water reducer, and stir rapidly for 5 minutes. Set the mixer to slow speed, add 500g of fine sand to the mixture, then add 4g of water reducer and 10g of water, and stir rapidly for 5 minutes.

[0040] The mixed mixture is poured into a 15mm×100mm×400mm test mold for molding, demolded after 24 hours and put into a standard curing room for health preservation.

[0041] Cement: 42.5 grade ordinary Portland cement produced by a factory in Changchun is used.

[0042] Fly ash: First-class fly ash produced by a factory in Henan is used.

[0043] Sand grains: Ultra-fine river sand with a maximum grain size of 0.6 mm is used.

[0044] Fiber: Polypropylene monofilament fiber produced by a factory in Beijing, with a diameter of 30 μm, a length of 12 mm, a Y-shaped cross-section,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com