Centrifugal water removal automatic cleaning dust removal device

An automatic cleaning and dust removal device technology, applied in the direction of combined devices, vacuum cleaners, separation methods, etc., can solve the problems of secondary pollution, unfavorable service life, limited application range, etc., achieve secondary pollution of water and dust removal, and prevent secondary pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is further explained below with reference to the accompanying drawings and examples:

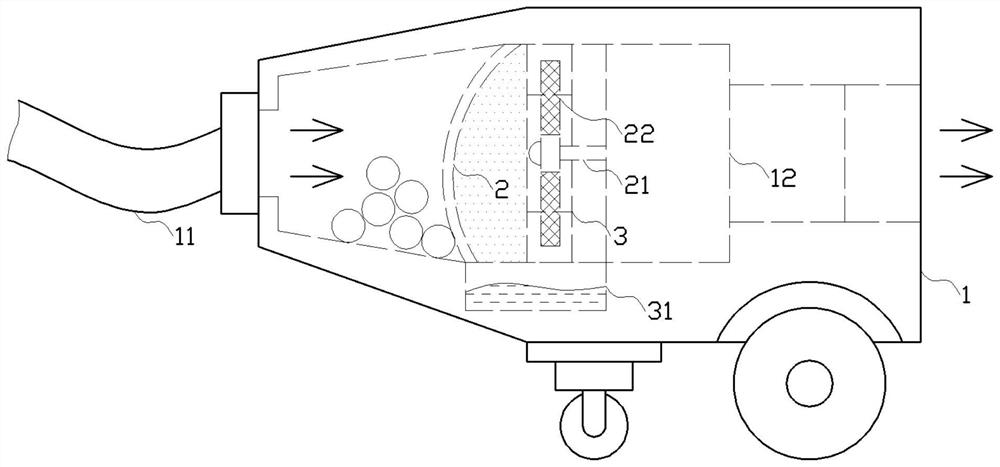

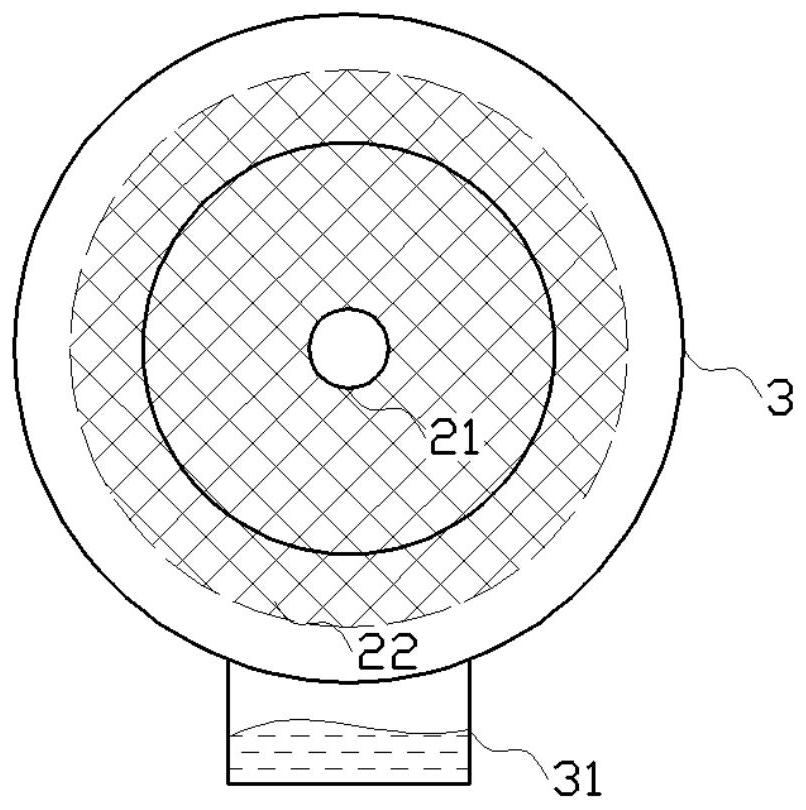

[0013] like figure 1 , figure 2 , image 3 The embodiment shown, the automatic centrifugal cleaning water removal by the dust removing device is a fan and the dust is sucked into the cleaner water, and then the dust, debris and the water layer was separated by filtration, so that dust and water into the secondary filtered; and the water absorbed by the water-absorbing layer and into the storage box under centrifugation, so that water and dust separation; fused with water after the closing device falls under gravity dust storage box, so that facilitate cleaning of the apparatus, which comprises a cleaner body 1, the filter module 2 and the separation module 3; the cleaner main body 11 comprises a suction duct, the suction duct 11 is mounted at the inlet end of the cleaner body, the cleaner body a motor is provided inside the module 12, the module 12 includes a fan moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com