A submerged reducer

A reducer and subordinate technology, applied in the direction of mechanical equipment, belts/chains/gears, transmission parts, etc., can solve the problems of high waterproof performance requirements, poor waterproof performance of reducers, unsuitable for underwater operations, etc., to achieve sealing Excellent performance, reliable sealing performance, enhanced resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

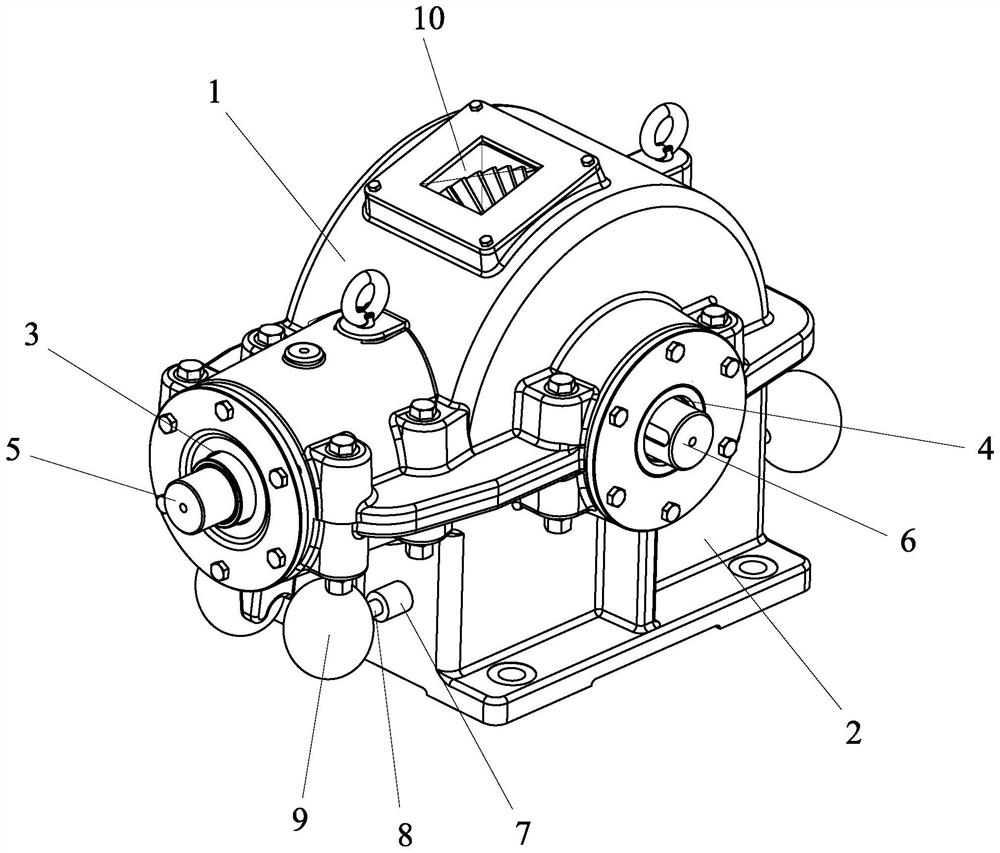

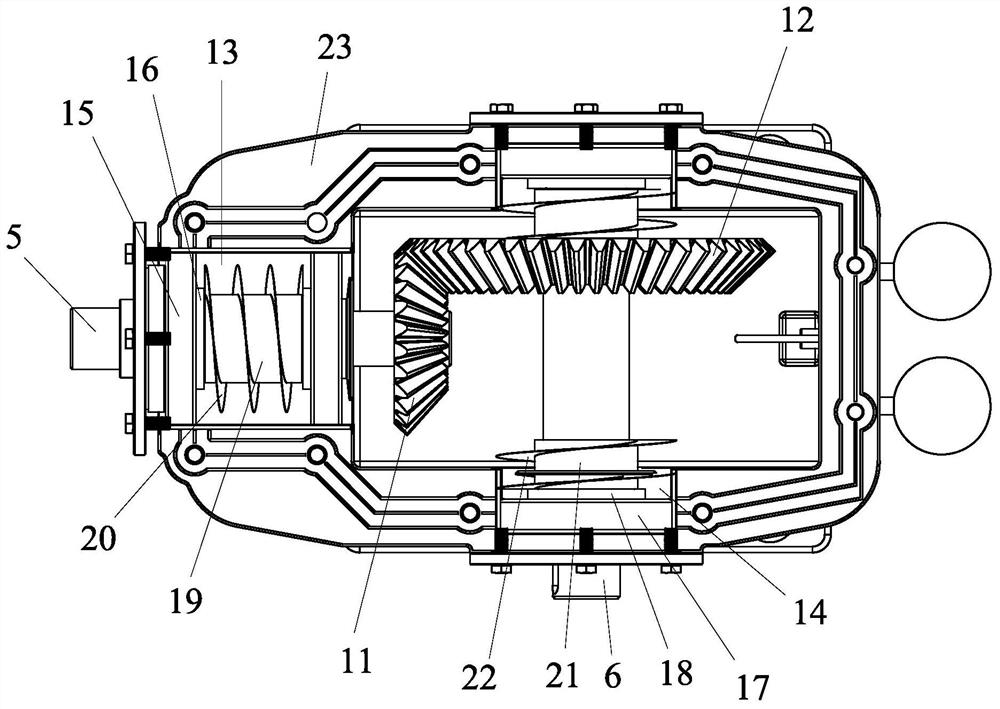

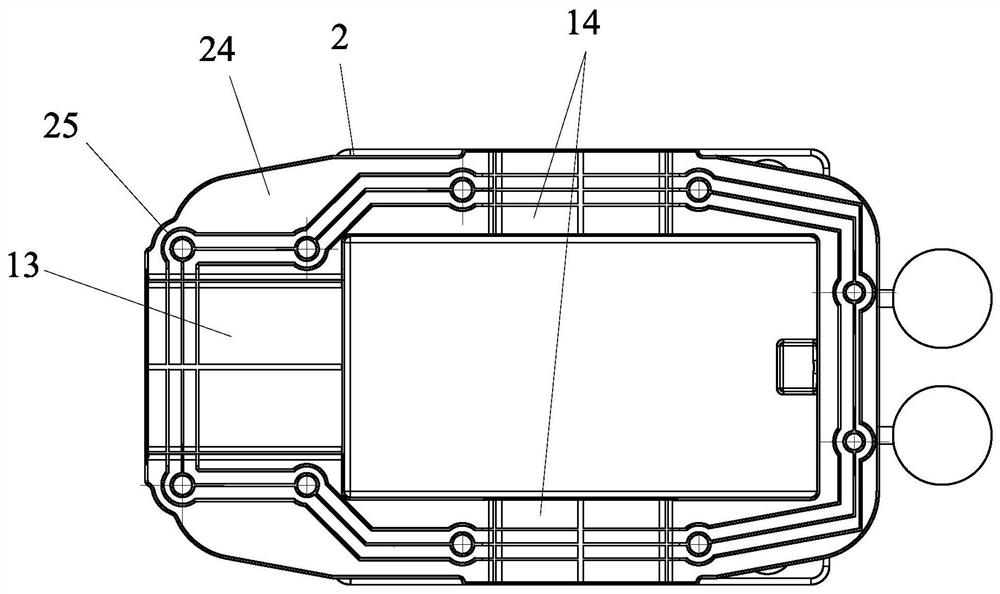

[0034] Embodiment: a kind of submerged speed reducer, constitutes as Figure 1-8Shown, comprise lower box body 2 and upper box body 1, upper box body 1 and lower box body 2 are bolted together, and the surface of described upper box body 1 and lower box body 2 is all provided with spray paint layer, can improve The corrosion resistance of the reducer. The top of the upper box 1 is provided with a transparent observation plate 10, which is an acrylic plate, which is convenient for the staff to observe the internal condition of the reducer and facilitate maintenance; the upper box 1 is provided with an upper hole 28 at the end, The lower box body 2 is provided with an end lower hole 13, and the upper hole 28 and the lower end hole 13 form an input hole 3. The upper semicircular holes 29 are provided on both sides of the upper box body 1, and the upper semicircular holes 29 are arranged on both sides of the lower box body 2. A lower semicircular hole 14 is provided, and the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com