An assembled wall panel

A prefabricated, wall panel technology, used in buildings, building components, building structures, etc., can solve the problems of low vibration comfort, poor bearing capacity, and a large amount of labor for processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

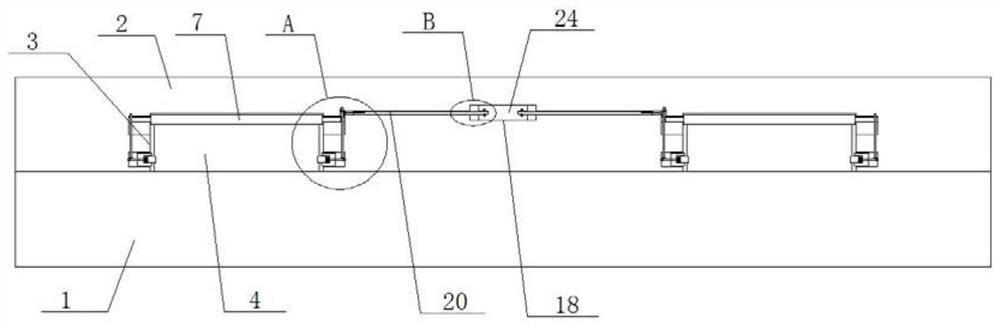

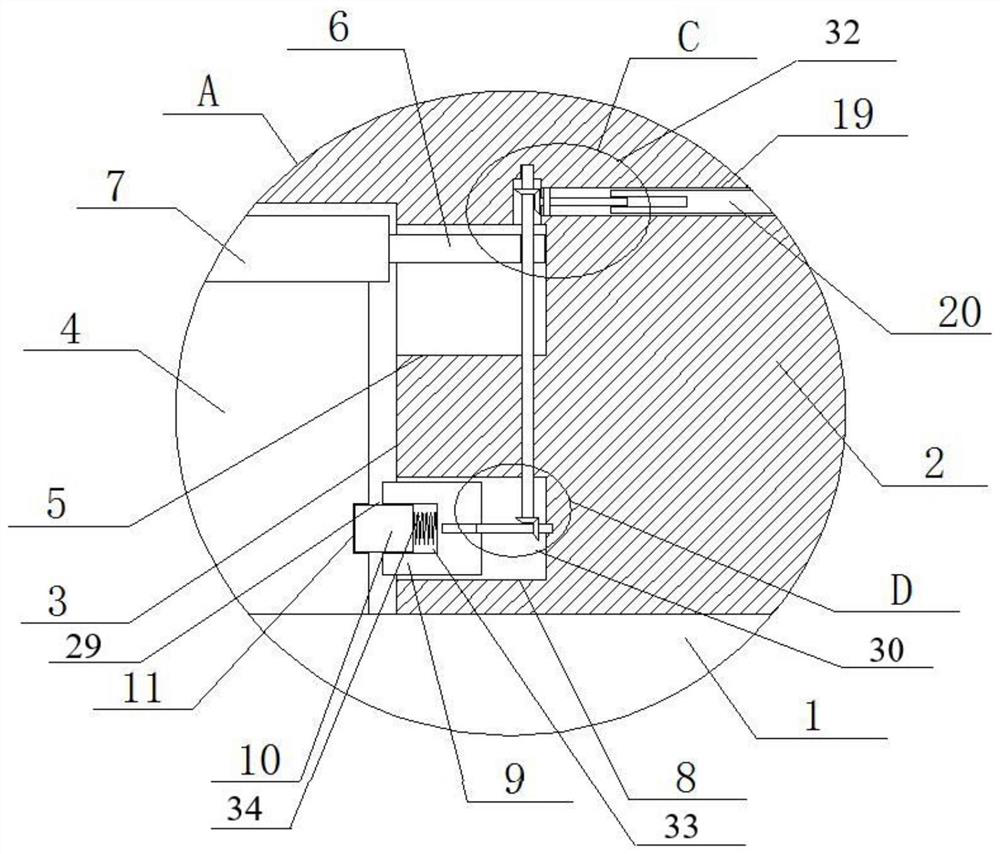

[0045] Such as Figure 1 to Figure 5 As shown, the present invention provides a kind of assembled wallboard, and this wallboard comprises:

[0046] The first wallboard 1, two installation seats 4 are arranged on one side of the first wallboard 1, and both sides of the installation seat 4 are provided with limiting grooves 11;

[0047] The second wallboard 2, two installation grooves 3 are arranged on one side of the second wallboard 2, and a fixing groove 8 is provided on the inner wall of the installation groove 3, and a rotating groove 36 is arranged at the bottom of the fixing groove 8, and the The inside of the fixed groove 8 is provided with a fixed mechanism 29, one end of the fixed mechanism is connected with a transmission mechanism 30, the inner side of the fixed groove 8 is provided with a chute 5, the inner wall of the chute 5 is provided with a groove 16, the A slide plate 6 is arranged in the chute 5, and a control plate 7 is connected between the left and right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com