Hanging belt conveyer

A belt conveyor and hanging technology, applied in the direction of conveyor, conveyor objects, transportation and packaging, can solve the problems of narrow space, high construction cost, low installation and disassembly efficiency, etc. The effect of construction efficiency and convenient movement and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

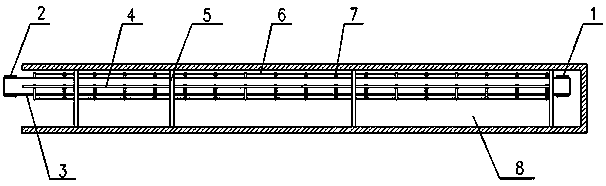

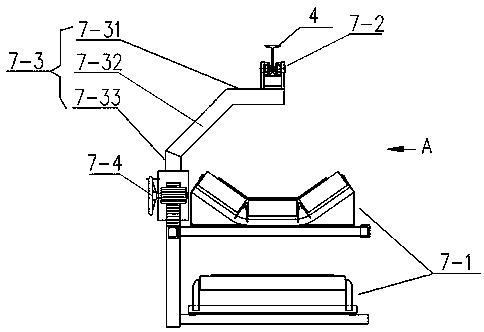

[0023] Such as figure 1 and Figure 3~6 As shown, the present invention provides a hanging belt conveyor, comprising a nose 1, a tail 2 and a conveyor belt 3, the conveyor belt 3 is connected to the nose 1 and the tail 2, and also includes a main beam 4 , support beam 5, connecting rod assembly 6 and hanging unit 7, the main beam 4 is an I-shaped steel structure, the hanging unit 7 is provided with multiple groups, and the hanging unit 7 is rollingly connected on the main beam 4 , the connecting rod assembly 6 is horizontally connected between two adjacent groups of suspension units 7, the main beam 4 is suspended in the roadway 8 through a plurality of supporting beams 5, and the nose 1 and the tail 2 are respectively Correspondingly arranged at both ends of the main beam 4, and the main beam 4 is correspondingly arranged above the centerline of the conveyor belt 3, and the hanging unit 7 is provided with a set of idlers 7-1, and the set of idlers 7-1 supports Below the con...

Embodiment 2

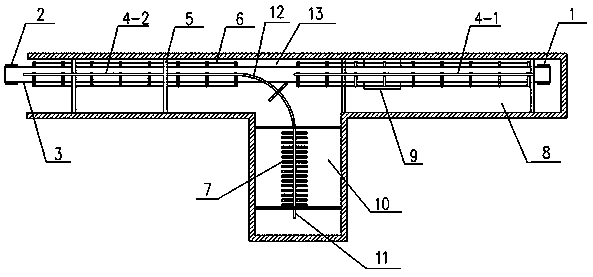

[0028] Such as figure 2 As shown in ~ 6, the present invention provides a kind of hanging belt type conveyor, comprises machine head 1, machine tail 2, conveyer belt 3, assembly storehouse 10 and storage belt device 9, and described conveyer belt 3 is connected on machine head 1 And on the tail 2, it also includes a main beam 4, a support beam 5, a connecting rod assembly 6 and a suspension unit 7, the suspension unit 7 is provided with multiple groups, and the support beam 5 is arranged at two sides of the roadway 8 at intervals. On the side and side walls, the top of the main beam 4 is connected to the support beam 5, the suspension unit 7 is rollingly connected to the main beam 4, and the connecting rod assembly 6 is horizontally connected to two adjacent groups of suspension units 7. Between, the head 1 and the tail 2 are respectively arranged at the two ends of the main beam 4, and the main beam 4 is correspondingly arranged above the center line of the conveyor belt 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com