Gate-type axle assembly

A portal-type axle and assembly technology, which is applied in the direction of axles, wheels, and vehicle parts, can solve the problems of small space on the construction site, slow walking speed, and obstacles to the progress of the project, so as to reduce manufacturing costs and maintenance costs, and climb hills. Strong load capacity and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with the accompanying drawings.

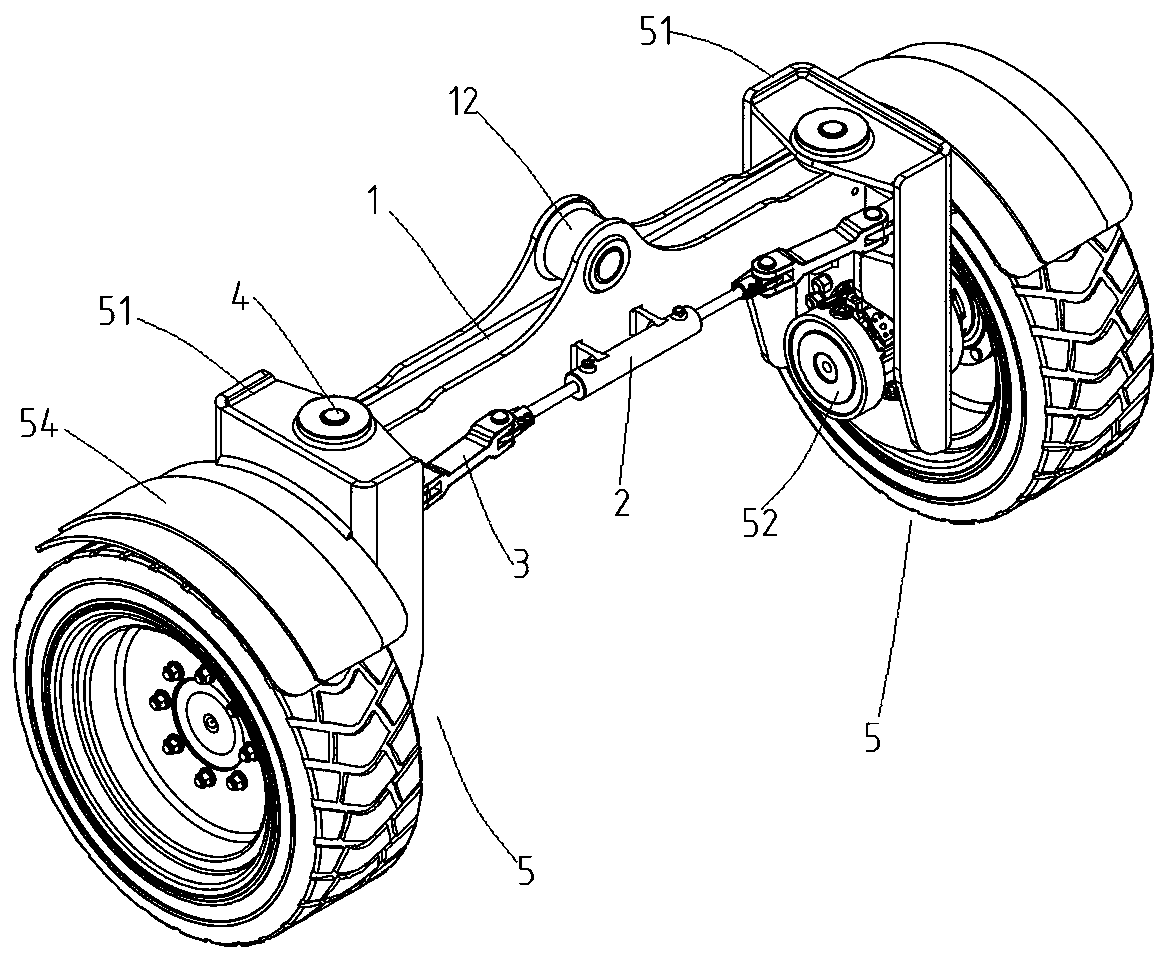

[0023] A portal axle assembly, comprising a horizontally arranged bridge 1 and wheel assemblies 5 installed at both ends of the bridge 1, the wheel assembly 5 includes wheels 53, a motor 52 for driving the wheels 53 and a bracket 51, the The lower end of the bracket 51 is connected to the axle of the wheel 53, and the upper end is connected to the end of the bridge 1.

[0024] In the above portal axle assembly, the bridge 1 is horizontally provided with a steering cylinder 2 with double telescopic rods. Oil cylinder 2 is hinged, and the other end is hinged with support 51 . The bracket 51 is provided with an ear plate 56 , and the wheel 53 is provided with a fender 54 .

[0025] In the above-mentioned portal axle assembly, the bracket 51 has a C-shaped section and is vertically arranged, and the two ends of the bridge 1 are pinned to the upper part of the vehicle fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com