Transformer substation post insulator cleaning device

A technology for post insulators and cleaning equipment, applied in cleaning methods and utensils, cleaning methods using liquids, cleaning methods using tools, etc., can solve problems such as not easy to remove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

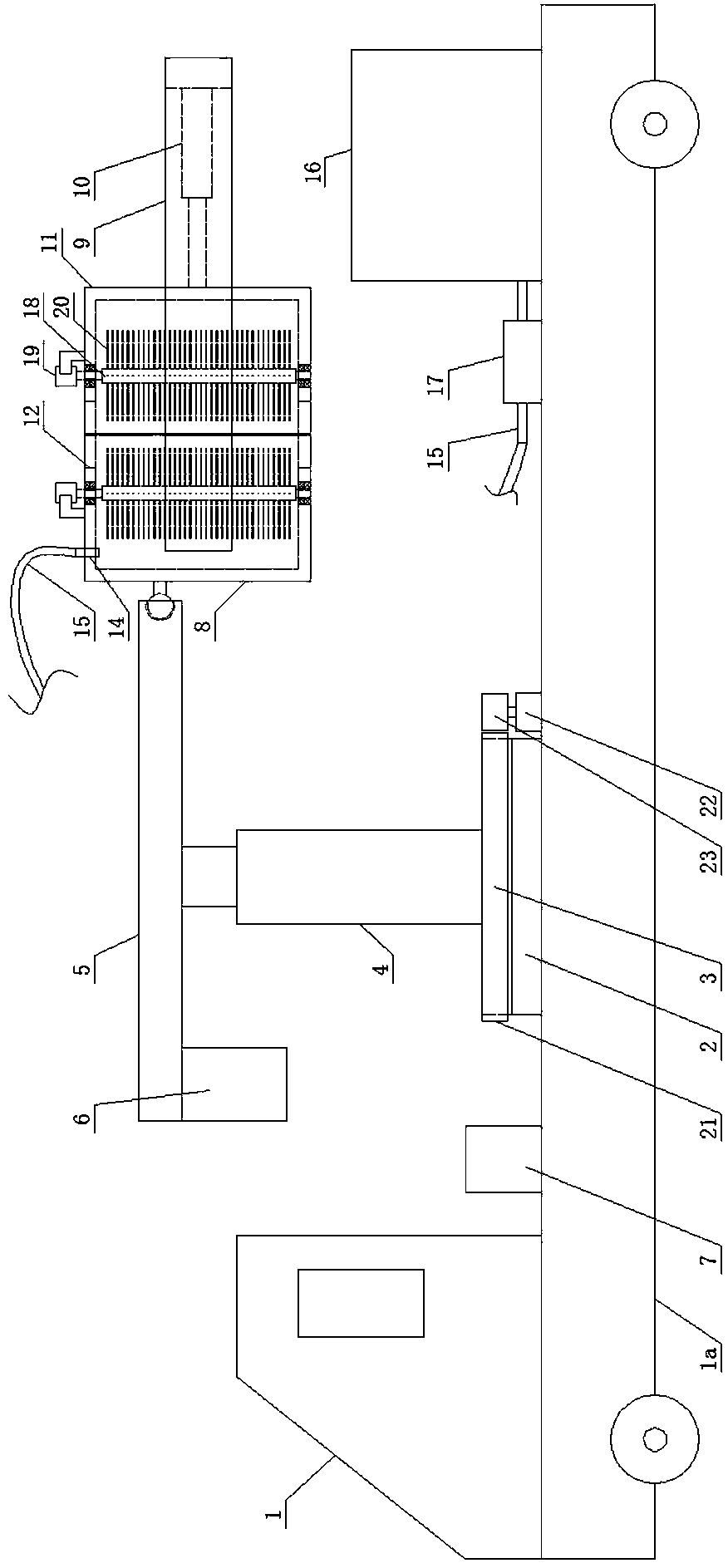

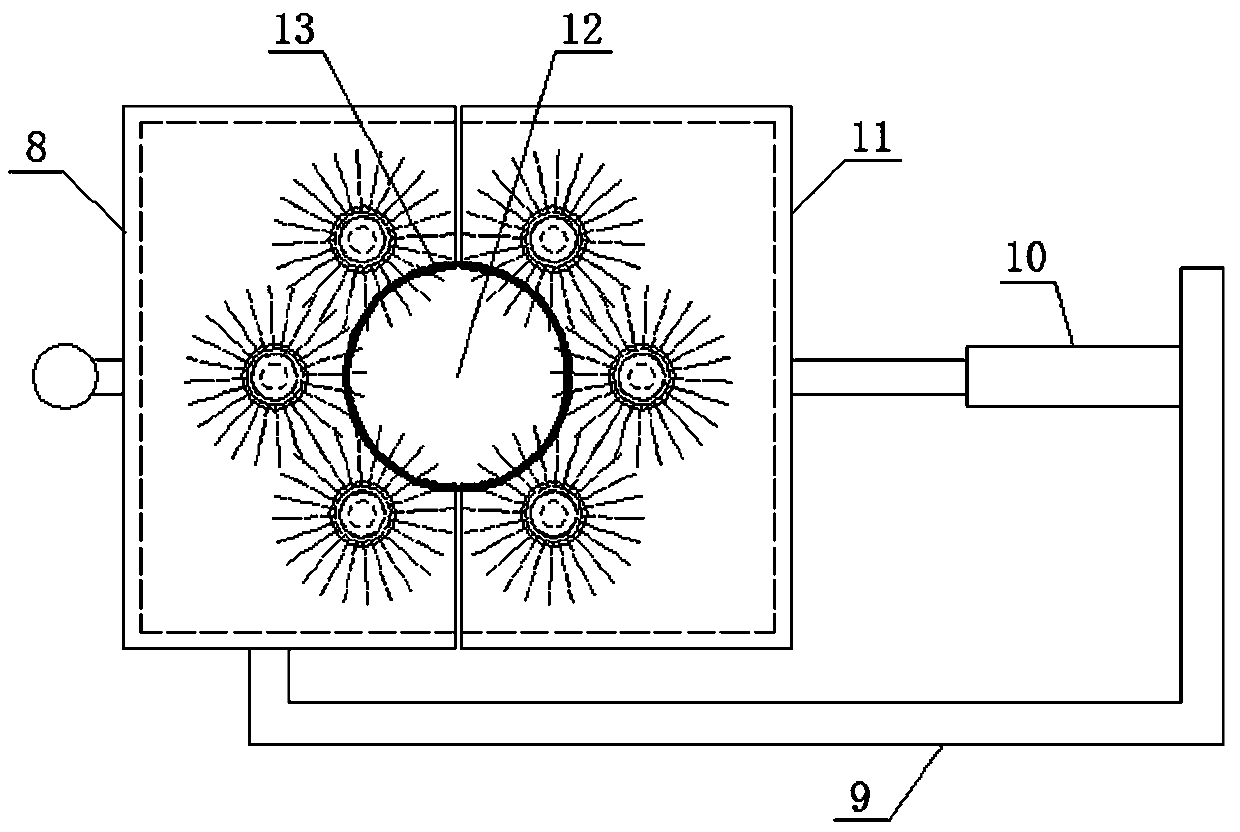

[0042] Such as figure 1 and figure 2 As shown, a substation post insulator cleaning equipment includes a trolley body 1, a circular base 3 is provided on the vehicle plate 1a of the trolley body 1 through a slewing support 2, and a first automatic telescopic Rod 4, horizontal beam 5 is arranged on the first automatic telescopic rod 4, the left end of the beam 5 is provided with a counterweight 6, the right end of the beam 5 is ball-hinged with a cleaning mechanism, the car plate 1a of the trolley body 1 A rotary drive mechanism for controlling the rotation of the base 3 is provided on it, and a control mechanism 7 for controlling the first automatic telescopic rod 4 , the cleaning mechanism and the rotary drive mechanism is provided on the vehicle plate 1 a of the trolley body 1 .

[0043] The cleaning mechanism includes a first half-shell 8 that is ball-hinged to the right end of the beam 5, a half-frame connecting rod 9 is arranged on the side of the first half-shell 8, an...

Embodiment 2

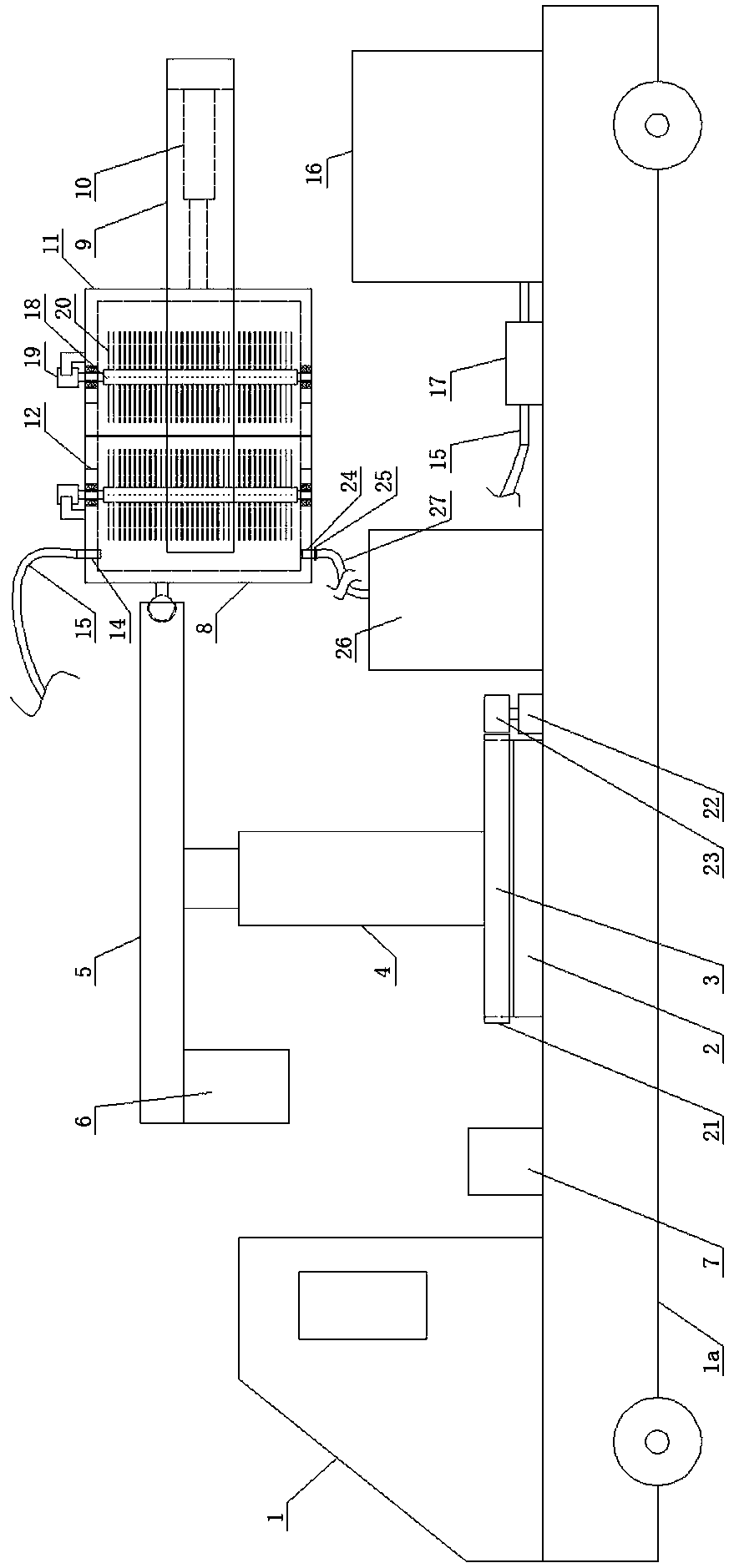

[0052] Such as image 3 and Figure 4 As shown, a substation post insulator cleaning equipment includes a trolley body 1, a circular base 3 is provided on the vehicle plate 1a of the trolley body 1 through a slewing support 2, and a first automatic telescopic Rod 4, horizontal beam 5 is arranged on the first automatic telescopic rod 4, the left end of the beam 5 is provided with a counterweight 6, the right end of the beam 5 is ball-hinged with a cleaning mechanism, the car plate 1a of the trolley body 1 A rotary drive mechanism for controlling the rotation of the base 3 is provided on it, and a control mechanism 7 for controlling the first automatic telescopic rod 4 , the cleaning mechanism and the rotary drive mechanism is provided on the vehicle plate 1 a of the trolley body 1 .

[0053] The cleaning mechanism includes a first half-shell 8 that is ball-hinged to the right end of the beam 5, a half-frame connecting rod 9 is arranged on the side of the first half-shell 8, an...

Embodiment 3

[0063] Such as Figure 5 and Figure 6 As shown, the difference between it and Embodiment 2 is that a second rubber layer 28 for sealing is provided at the junction of the first half-shell 8 and the second half-shell 11 .

[0064] In this embodiment, in order to increase the sealability of the joint between the first half shell and the second half shell, a second seal that acts as a seal is provided at the joint between the first half shell and the second half shell. rubber layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com