Method for preparing array substrate and display panel

A technology of array substrates and substrates, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of process yield loss, complex structure, increased time cost, material cost, etc., and achieve cost saving, time saving, and cost saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055] The preparation method of the array substrate 10 of the present invention includes the following steps:

[0056] S1) Provide a substrate 110, the substrate 110 is a glass substrate, which is convenient to undertake subsequent thin film transistor manufacturing processes.

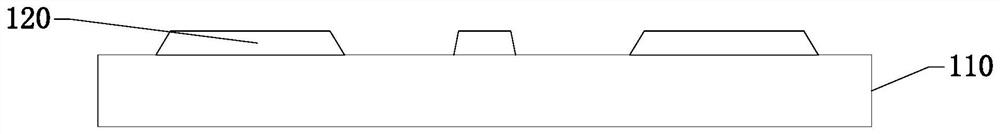

[0057] S2) As shown in FIG. 1, a layer of light-shielding layer 120 is prepared on the substrate 110, and the light-shielding layer 120 is a high-reflection gold

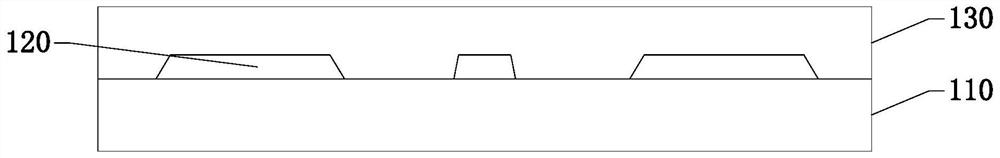

[0058] S3) As shown in FIG. 2 , a first insulating layer 130 is covered on the light shielding layer 120, because the light shielding layer 120

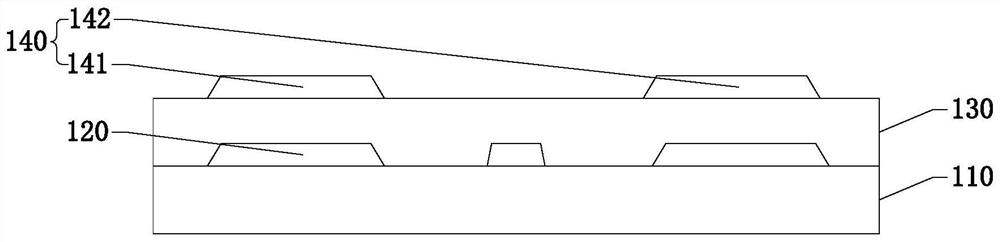

[0059] S4) As shown in FIG. 3, a layer of IGZO layer 140 is formed on the first insulating layer 130, which is formed by a patterning process

[0060] S5) As shown in FIG. 4, a second insulating layer 150 is formed on the first insulating layer 130, and the second insulating layer

[0061] S6) As shown in FIG. 5, a photoresist layer 160 is formed on the second insulating layer 150 through a mask, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com