MVR evaporation system for radioactive waste liquid in nuclear power station and operation method thereof

A technology of radioactive waste liquid and evaporation system, applied in the field of radioactive waste liquid treatment and disposal of nuclear power plants, can solve the problem of easy scaling on the surface of the evaporator, and achieve the effects of saving primary energy, simple external interface and eliminating superheat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The nuclear power plant radioactive waste liquid MVR evaporation system and its operating method provided by the present invention will be further described in detail and completely below in conjunction with the embodiments. The embodiments described below are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

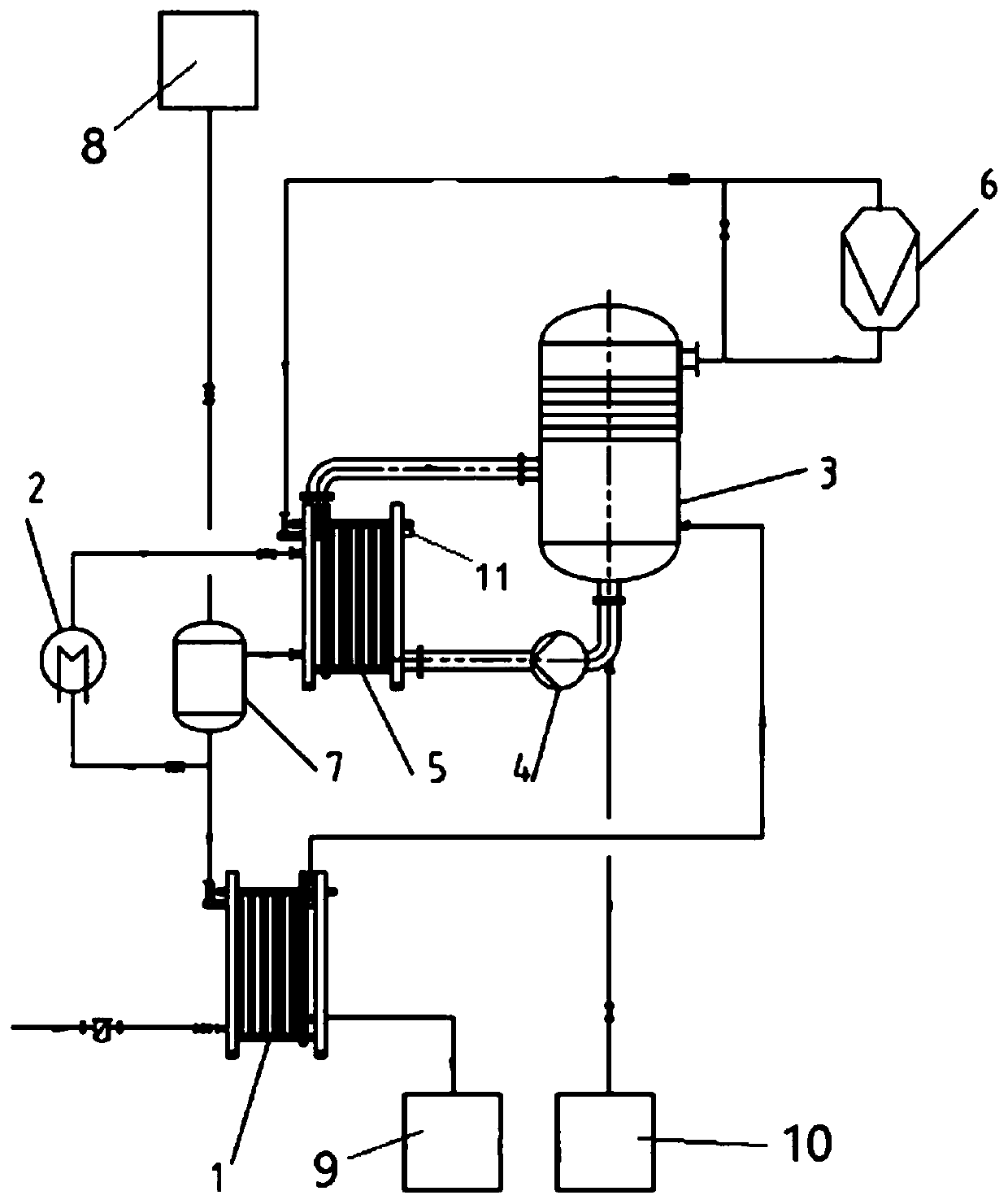

[0038] Nuclear power plant radioactive waste liquid MVR evaporation system, such as figure 1 As shown, it includes a preheater 1, an electric heating device 2, an evaporation tower 3, a circulation pump 4, a heater 5, a steam compressor 6 and a distillation tank 7.

[0039] The preheater 1 is a heat exchanger, and the inside of the preheater 1 is divided into two independent spaces, and the two independent spaces respectively flow through two streams of fluids with different temperatures for heat exchange, correspondingly, each The independent space has at least one entrance and one exit. One side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com