Method and system for state detection and maintenance of rail transit equipment

A technology of equipment status and rail transit, applied in general control system, test/monitor control system, control/regulation system, etc., can solve the problem of lack of long-term storage of equipment data, difficulty in maintaining transportation equipment and facilities, and taking a long time, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

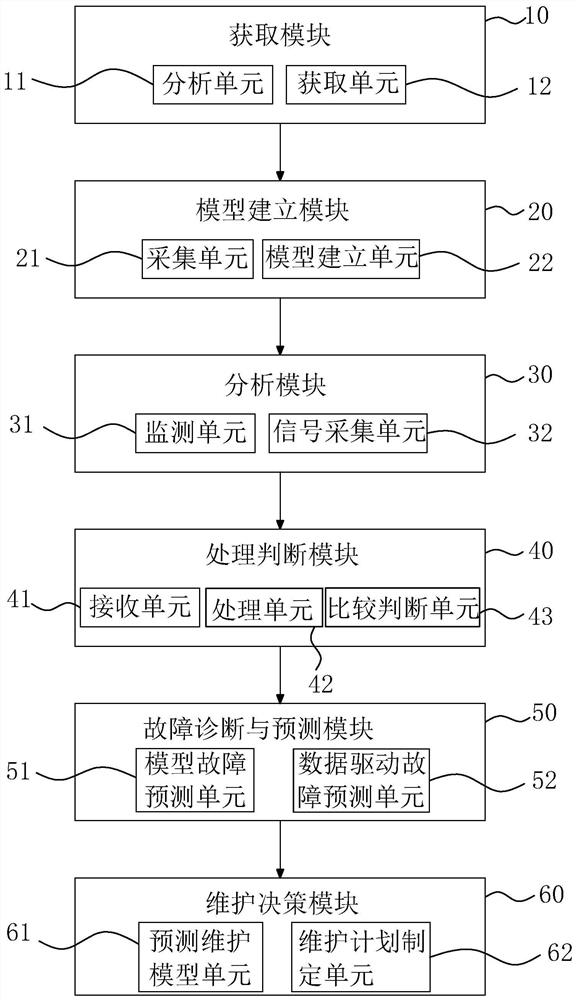

[0054] Embodiment one: refer to figure 1 The present invention discloses a state detection and maintenance system for rail transit equipment, including: an acquisition module 10, a model building module 20, an analysis module 30, a processing and judgment module 40, a fault diagnosis and prediction module 50, and a maintenance decision module 60. The acquisition module 10 is used to analyze the equipment or each component to obtain the fault conditions and influencing factors of the equipment or each component; the model building module 20 is used to simulate the life cycle of the equipment or each component under the condition that the influencing factors affect the application scenario of the equipment or each component data and establish a dynamic model; the analysis module 30 is used to analyze the main influencing factors and characteristics of failures, hidden dangers, and service life of different equipment or components for different detection objects; the processing and ...

Embodiment 2

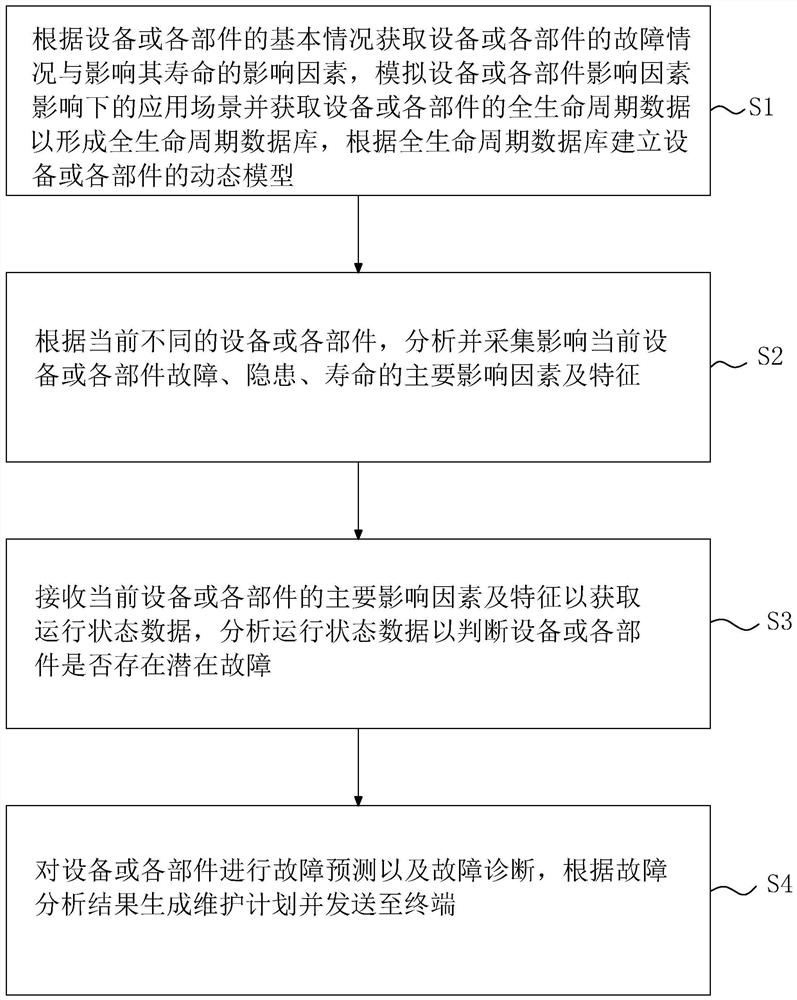

[0065] Embodiment two: refer to figure 2 , the embodiment of the present invention discloses a method for detecting and maintaining the status of rail transit equipment, comprising the following steps:

[0066] Step S1: According to the basic situation of the equipment or each component, obtain the fault condition of the equipment or each component and the influencing factors affecting its life, simulate the application scenario under the influence of the influencing factors of the equipment or each component, and obtain the full life cycle data of the equipment or each component To form a full life cycle database, and establish a dynamic model of equipment or components based on the full life cycle database;

[0067] Step S2: According to the current different equipment or components, analyze and collect the main influencing factors and characteristics that affect the failure, hidden danger and life of the current equipment or components;

[0068] Step S3: Receive the data ...

Embodiment 3

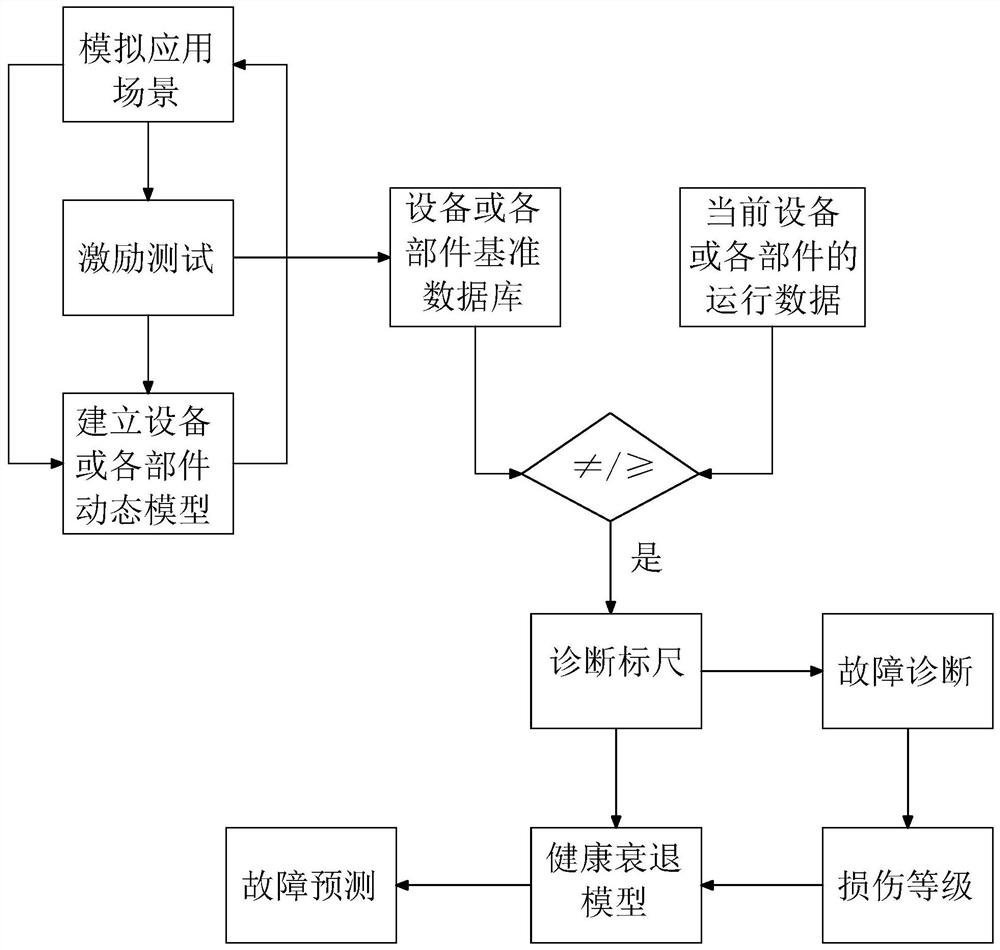

[0091] Embodiment three: as image 3 As shown, after analyzing the failure conditions and influencing factors of the equipment or each component, simulate the real application scene, take the stimulus test equipment or each component, and then establish the dynamic model of the equipment or each component, and continuously improve the equipment or each component through repeated simulation and testing. The dynamic model of each component, while collecting the benchmark database of the equipment or each component in continuous simulation and testing, that is, the temperature alarm threshold and voltage alarm threshold of the equipment or each component, and then measure the equipment or each component in the current system To collect the corresponding measurement data, and compare the measurement data with the alarm threshold in the equipment or each component database, if the measurement data exceeds the alarm threshold, start to judge the fault condition of the equipment or ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com