Ethylene-propylene rubber cable insulation aging simulation and evaluation method

A technology of cable insulation and ethylene-propylene rubber, which is applied in the field of ethylene-propylene rubber cable insulation aging simulation and evaluation, and can solve problems such as accelerated cable aging, shortened cable life, and no evaluation of cable aging status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

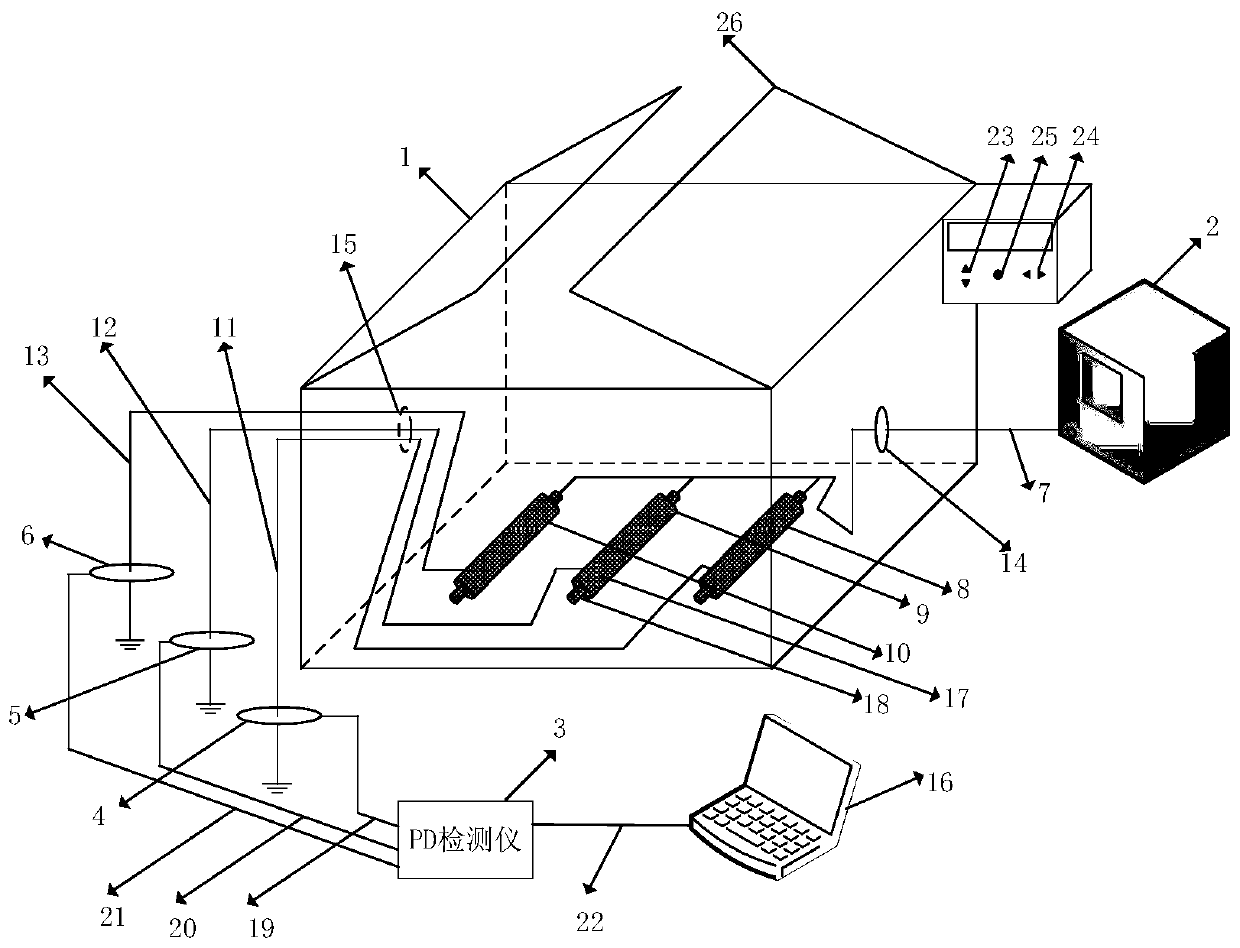

[0047] Step 1: Build a cable insulation aging test platform

[0048] Build a cable insulation aging test platform, which is mainly composed of a constant temperature aging box (1), a high-voltage power generator (2), a PD detector (3), a No. 1 high-frequency current transformer (4), and a No. 2 high-frequency current transformer. device (5), No. 3 high-frequency current transformer (6), high-voltage test line (7), No. 1 aging sample (8), No. 2 aging sample (9), No. 3 aging sample (10), No. 1 ground wire (11), No. 2 ground wire (12), No. 3 ground wire (13), high-voltage test line inlet hole (14), ground wire outlet hole (15), host computer (16), No. 1 Composed of optical fiber (19), No. 2 optical fiber (20), No. 3 optical fiber (21), and high-frequency signal transmission line (22), the high-voltage test line (7) is connected to the high-voltage power g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com