Single-spindle double-wheel belt combined structure false-twisting compact spinning device with broken end and breakpoint control

A technology of combined structure and concentrated spinning, applied in textiles and papermaking, etc., can solve the problems of increasing energy consumption, generating large energy consumption, and different mechanism settings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

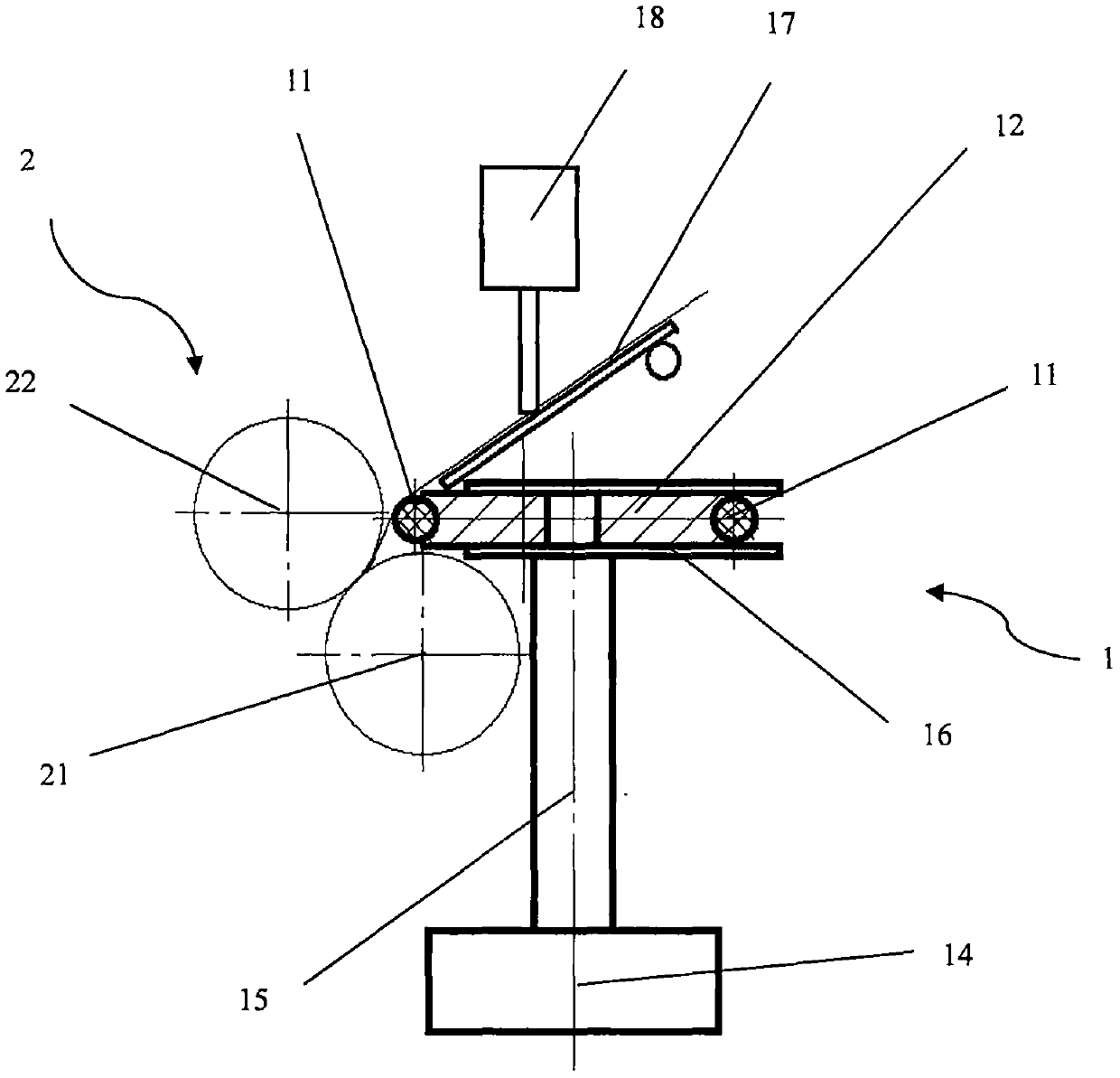

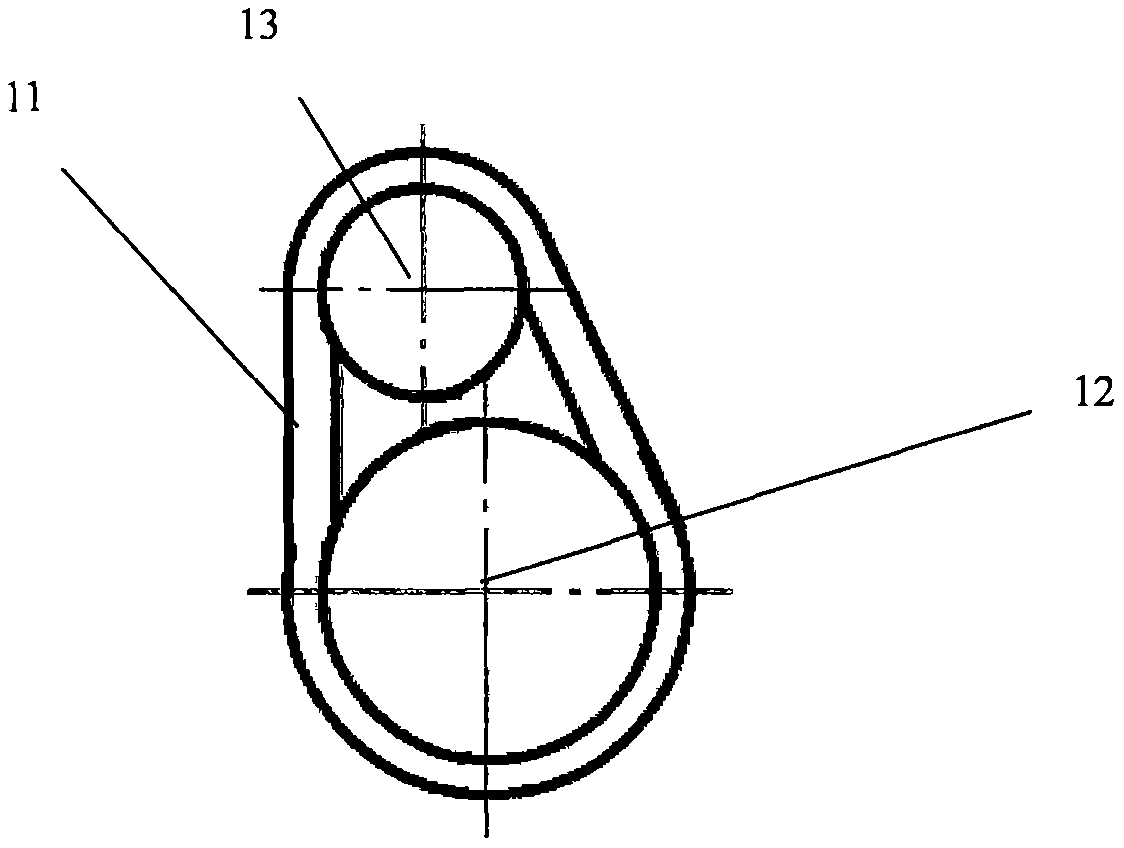

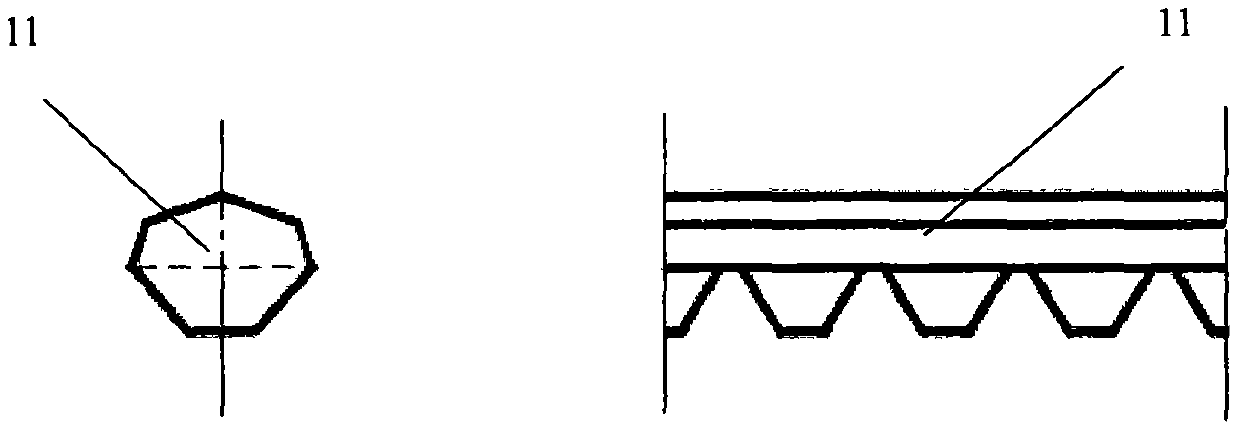

[0021] figure 1 As shown, a single-spindle double-pulley combined structure false twist compact spinning device with end-break point control, the device includes a friction belt 11, a driving wheel 12, a driven wheel 13, a driving wheel 14, a driving shaft 15, and a base 16. Hairiness suppressor 17, end break point control mechanism 18, single-spindle double-pulley combined structure false twist compact spinning device with end break point control 1 is located between the lead-out roller 2 and the front roller of the drafting mechanism of the spinning frame In between, the lead-out roller includes a lead-out bottom roller 21 and a lead-out top roller 22. The driving pulley 12 and the driven pulley 13 in the single-spindle double-pulley combined structure false-twisting compact spinning device are installed on the same base 16, and the friction belt 11 is set on the driving pulley. On the wheel 12 and the driven wheel 13, the driving wheel 12 and the driving wheel 14 are instal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com