High-accuracy microbial detection chip

A microbial detection, high-precision technology, applied in enzymology/microbiology devices, biomass post-processing, biomass pre-treatment, etc., can solve the problems of fluorescence signal interference, mixing, exceeding the photosensitive range, etc., to achieve fluorescence detection Accurate results, good wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

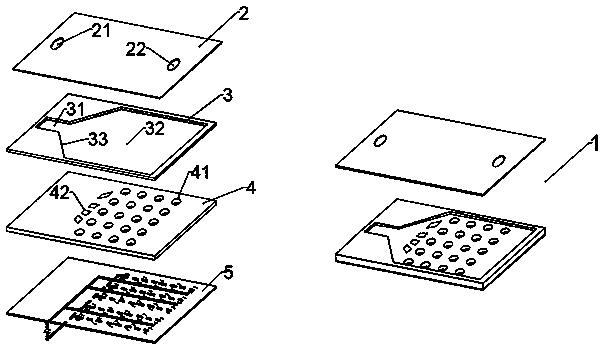

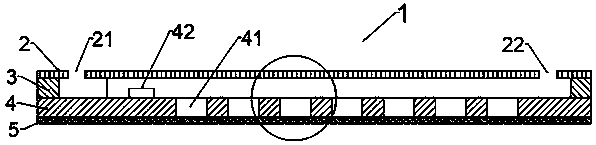

[0032] Such as figure 2 As shown, a high-precision microbial detection chip includes a cover layer 2, a microchannel layer 3, a microreaction chamber layer 4 and a base layer 5 stacked sequentially from top to bottom; the left and right sides of the cover layer 2 are respectively A sample inlet 21 and an outlet 22 are provided; the microchannel layer 3 has a receiving channel 31 and a distribution channel 32 and a gradually expanding channel 33 connecting the two; the receiving channel 31 communicates with the sample inlet 21, and the The distribution channel 32 communicates with the outlet 22; the micro-reaction chamber layer 4 is arranged with arrayed micro-reaction chambers 41, and the size of the distribution channel 32 can at least cover the array of micro-reaction chambers 41; the micro-reaction chamber layer 4 The lower part is provided with a base layer 5 .

[0033] Preferably, on the micro-reaction chamber layer 4, corresponding to the diverging channel 33, a number...

Embodiment 2

[0039] The difference from Example 1 is that the micro-reaction chamber layer 4 is made of hydrophobic material. First, attach or coat a peelable protective film layer on the upper and lower surfaces of the hydrophobic micro-reaction chamber layer 4 and cure the protective film layer; Form an array of micro-reaction chambers 41 on 4; carry out hydrophilic modification on the micro-reaction chamber layer 4 by coating a hydrophilic coating or acid corrosion; tear off the protective film layer to obtain micro-reaction chambers 41 with hydrophilic side walls And a micro-reaction chamber layer 4 with hydrophobic upper and lower surfaces.

Embodiment 3

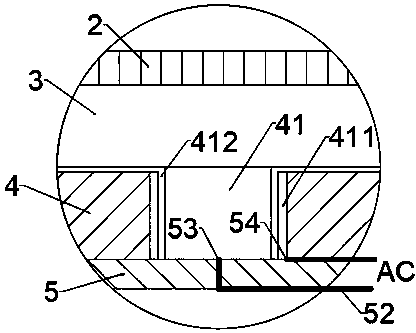

[0041] Such as figure 1 , 3 As shown in -6, the difference from Embodiments 1 and 2 is that the wall surface of the micro-reaction chamber 41 has variable surface properties.

[0042] Wherein, there is an annular electrode 411 corresponding to the periphery of the micro reaction chamber 41 on the sidewall of the micro reaction chamber 41 and the lower surface of the micro reaction chamber layer 4; the annular electrodes 411 of any two adjacent micro reaction chambers 41 411 are disconnected from each other; the ring electrode 411 surrounds the side wall of the whole micro reaction chamber 41; the upper surface of the ring electrode 411 and the micro reaction chamber layer 4 has a hydrophobic coating 412; the hydrophobic coating 412 Sealing the peripheral wall and top of the ring electrode 411, but not sealing the lower surface of the micro reaction chamber layer 4, so that the ring electrode 411 is exposed at the lower surface of the micro reaction chamber layer 4; Base laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com