Method for preparing bacterial fertilizer from glutamic acid fermentation waste liquid and application of bacterial fertilizer

A technology for fermenting waste liquid and glutamic acid, applied in the application, preparation of organic fertilizer, nitrogen fertilizer and other directions, can solve the problems of low processing efficiency and high processing cost of vegetable straw waste, and meet the requirements of green production, low fermentation cost and degradation. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

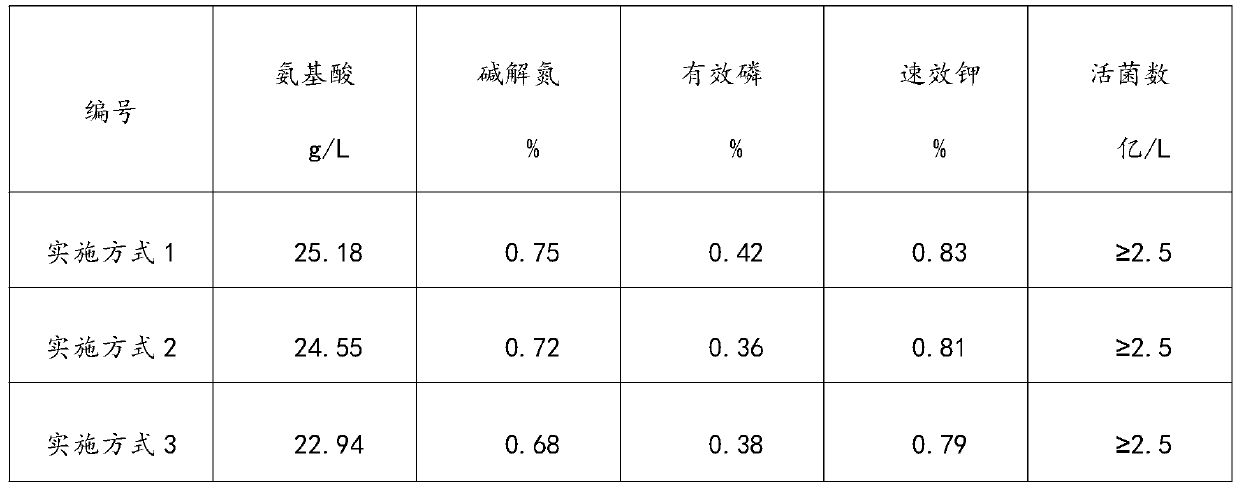

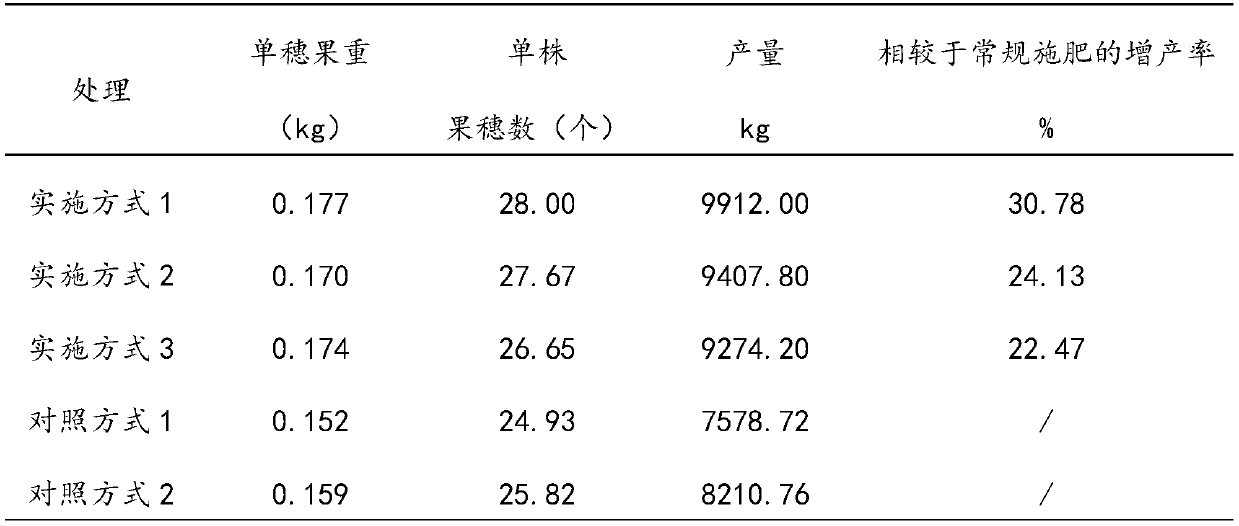

Embodiment approach 1

[0037] This embodiment provides a method for preparing bacterial fertilizer from glutamic acid fermentation waste liquid, comprising the following steps:

[0038] S1 collects vegetable straw waste, cuts and pulverizes, and obtains straw waste A with a length of ≤ 2 cm;

[0039] S2 Mix 200 parts by weight of glutamic acid fermentation waste liquid, 100 parts by weight of straw waste A obtained in step S1, and 1000 parts by weight of water, wherein the pH value of glutamic acid fermentation waste liquid is 5.5, and the water content is 32%. Obtain mixture A;

[0040] S3 adds 4 parts by weight of live saccharomyces preparations, 4 parts by weight of live lactic acid bacteria preparations, 2 parts by weight of live bacillus subtilis preparations and 2 parts by weight of live Trichoderma chrysanthemum preparations in the mixture A obtained in step S2 , wherein the number of effective viable bacteria in the live yeast preparation, the live lactic acid bacteria preparation, the live...

Embodiment approach 2

[0044] This embodiment provides a method for preparing bacterial fertilizer from glutamic acid fermentation waste liquid, which includes the following steps:

[0045] S1 collects vegetable straw waste, cuts and pulverizes, and obtains straw waste A with a length of ≤ 2 cm;

[0046] S2 Mix 260 parts by weight of glutamic acid fermentation waste liquid, 80 parts by weight of straw waste A obtained in step S1, and 900 parts by weight of water, wherein the pH value of glutamic acid fermentation waste liquid is 5, and the moisture content is 35%. Obtain mixture A;

[0047]S3 adds 2 parts by weight of live saccharomyces preparations, 4 parts by weight of live lactic acid bacteria preparations, 1 part by weight of live bacillus subtilis preparations and 1 part by weight of live Trichoderma chrysanthemum preparations in the mixture A obtained in step S2 , wherein the number of effective viable bacteria in the live yeast preparation, the live lactic acid bacteria preparation, the live...

Embodiment approach 3

[0051] This embodiment provides a method for preparing bacterial fertilizer from glutamic acid fermentation waste liquid, which includes the following steps:

[0052] S1 collects vegetable straw waste, cuts and pulverizes, and obtains straw waste A with a length of ≤ 2 cm;

[0053] S2 Mix 220 parts by weight of glutamic acid fermentation waste liquid, 120 parts by weight of straw waste A obtained in step S1, and 1050 parts by weight of water, wherein the pH value of glutamic acid fermentation waste liquid is 6.5, and the water content is 30%. Obtain mixture A;

[0054] S3 adds 2 parts by weight of live saccharomyces preparations, 2 parts by weight of live lactic acid bacteria preparations, 3 parts by weight of live bacillus subtilis preparations and 2 parts by weight of live Trichoderma chrysanthemum preparations in the mixture A obtained in step S2 , wherein the number of effective viable bacteria in the live yeast preparation, the live lactic acid bacteria preparation, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com