Production process for preparing cold-rolled thin-wall sleeve

A production process and thin-wall sleeve technology, applied in the field of cold-rolled sleeves, can solve the problems of low production efficiency, difficult processing, high raw material cost, etc., and achieve the effects of high production efficiency, low production cost and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

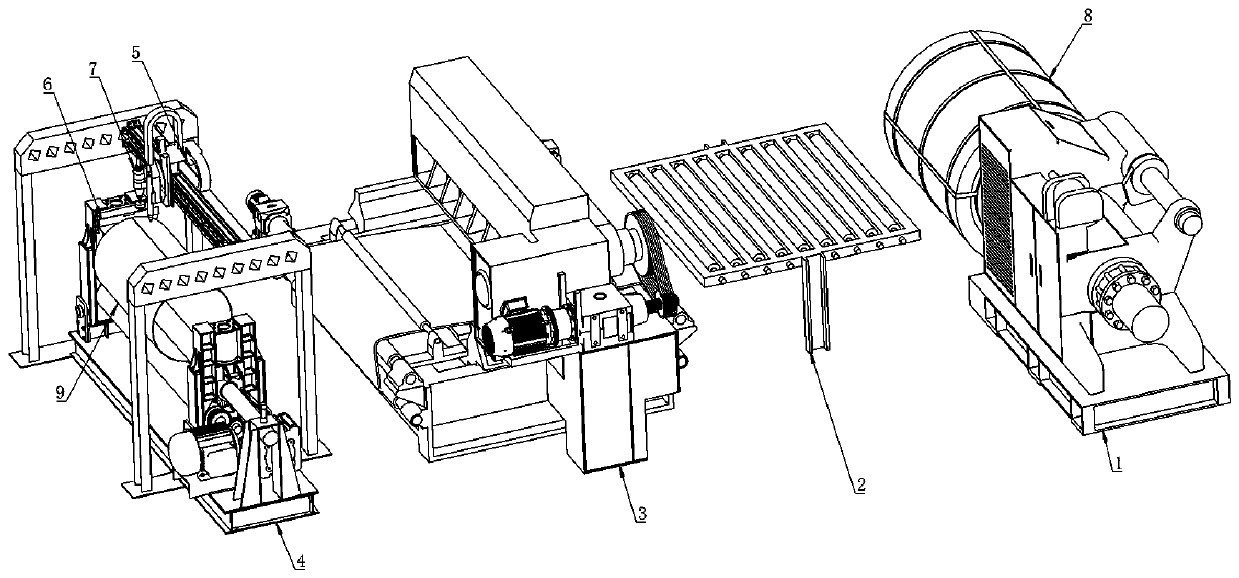

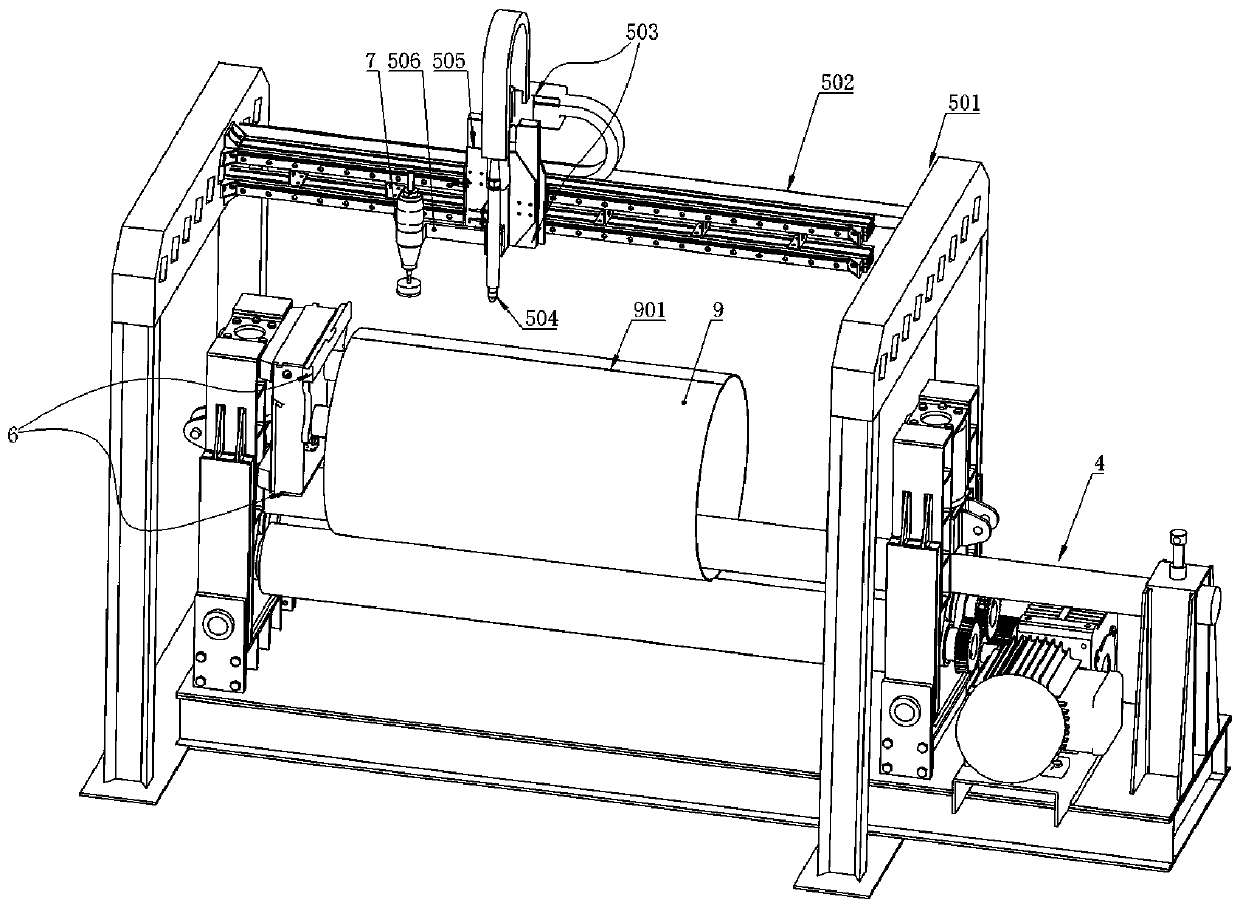

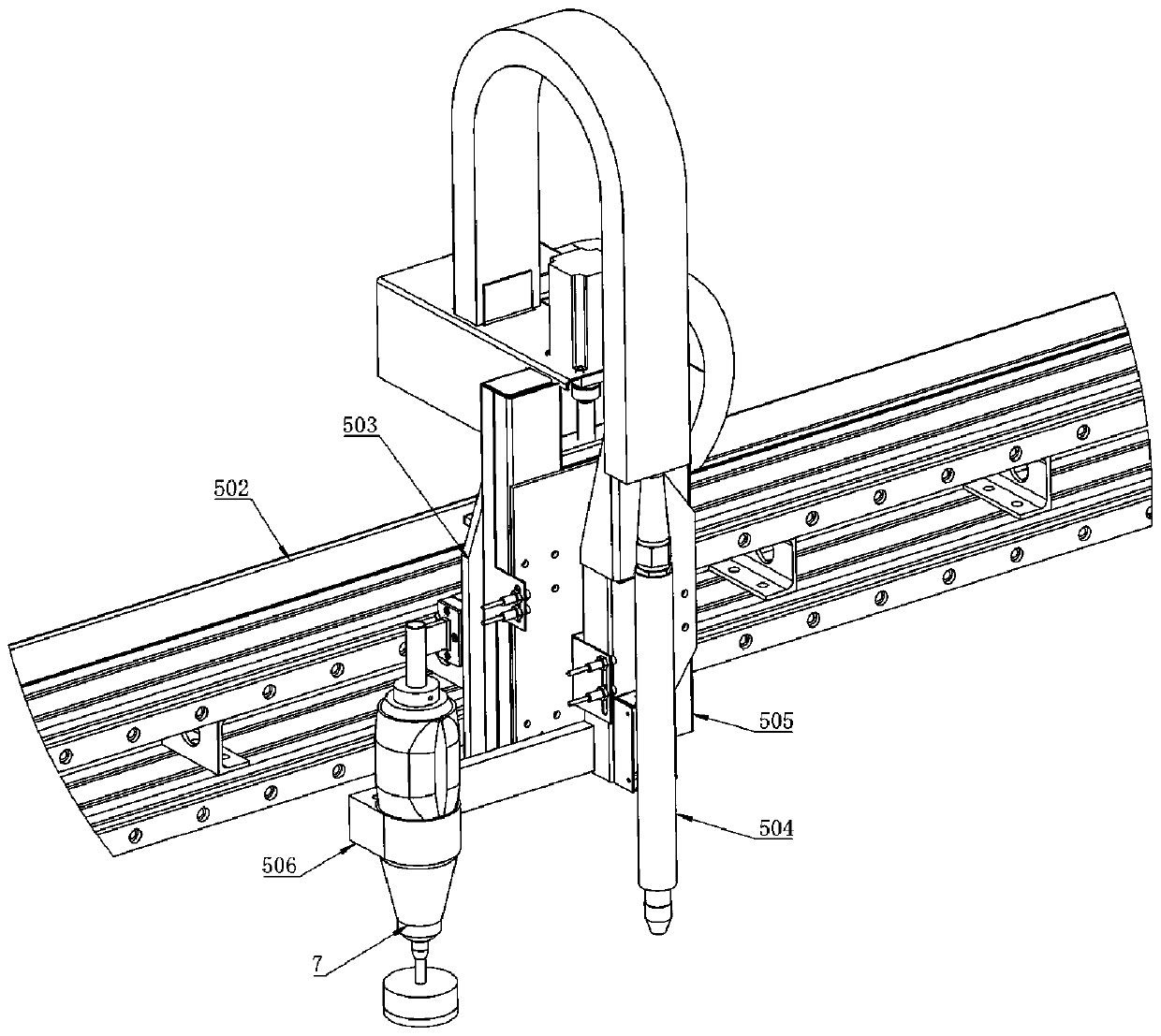

[0037] Specific embodiment one: combination Figure 1-5 As shown, a production process for preparing cold-rolled thin-walled sleeves is characterized by: including: uncoiler 1, conveying roller 2, shearing machine 3, special leadless two-roller coiling machine 4, special straight seam Automatic welding machine 5, self-made hydraulic calibration machine 6, automatic polishing machine 7, steel strip 8 and sleeve 9; the processing steps of preparing cold-rolled thin-wall sleeve 9 are as follows:

[0038] i) Selection of raw materials, material Q345-B, cold-rolled sheet with thickness 3-8mm, tensile strength of material 550-600 Mpa;

[0039] j) Blanking: Uncoiler 1 feeds and adopts shear 3 for blanking, controlling blanking tolerance, length and width tolerance ≤ 1.5mm;

[0040] k) Rolling plate: use a special headless two-roller plate rolling machine with 4 rolls;

[0041] l) Automatic welding: use a dedicated straight seam automatic welding machine 5 to surfacing butt weld 901;

[0042] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com