Full-automatic numerical control drilling machine for brake pad steel backing and power head assembly used in full-automatic numerical control drilling machine

A CNC drilling machine, fully automatic technology, applied in the direction of boring/drilling, large fixed members, drilling/drilling equipment, etc., can solve the problems of accuracy and efficiency, and the processing accuracy and processing efficiency can not meet the requirements, etc., to achieve Guaranteed drilling accuracy, wide range of parameter control and high drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

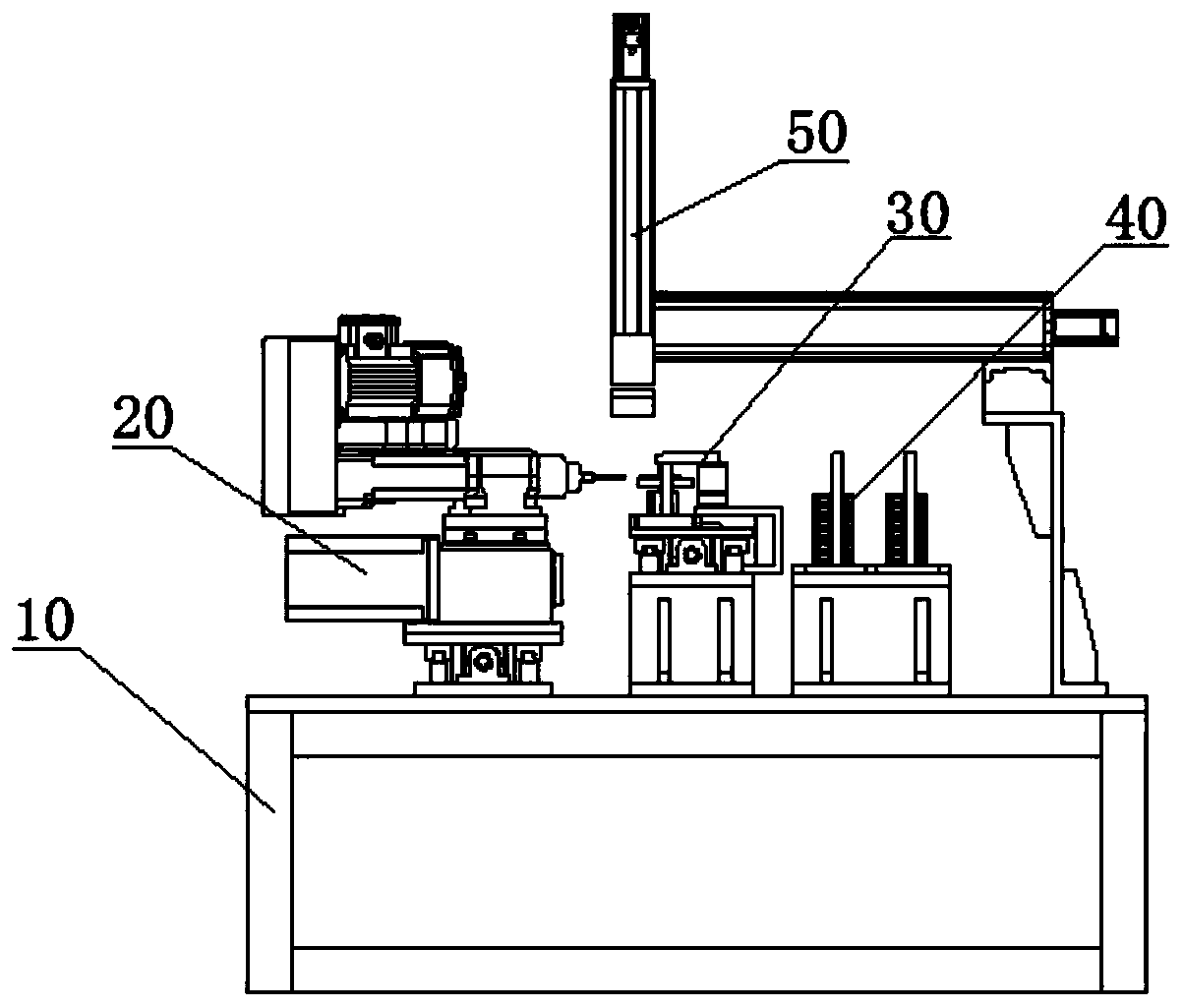

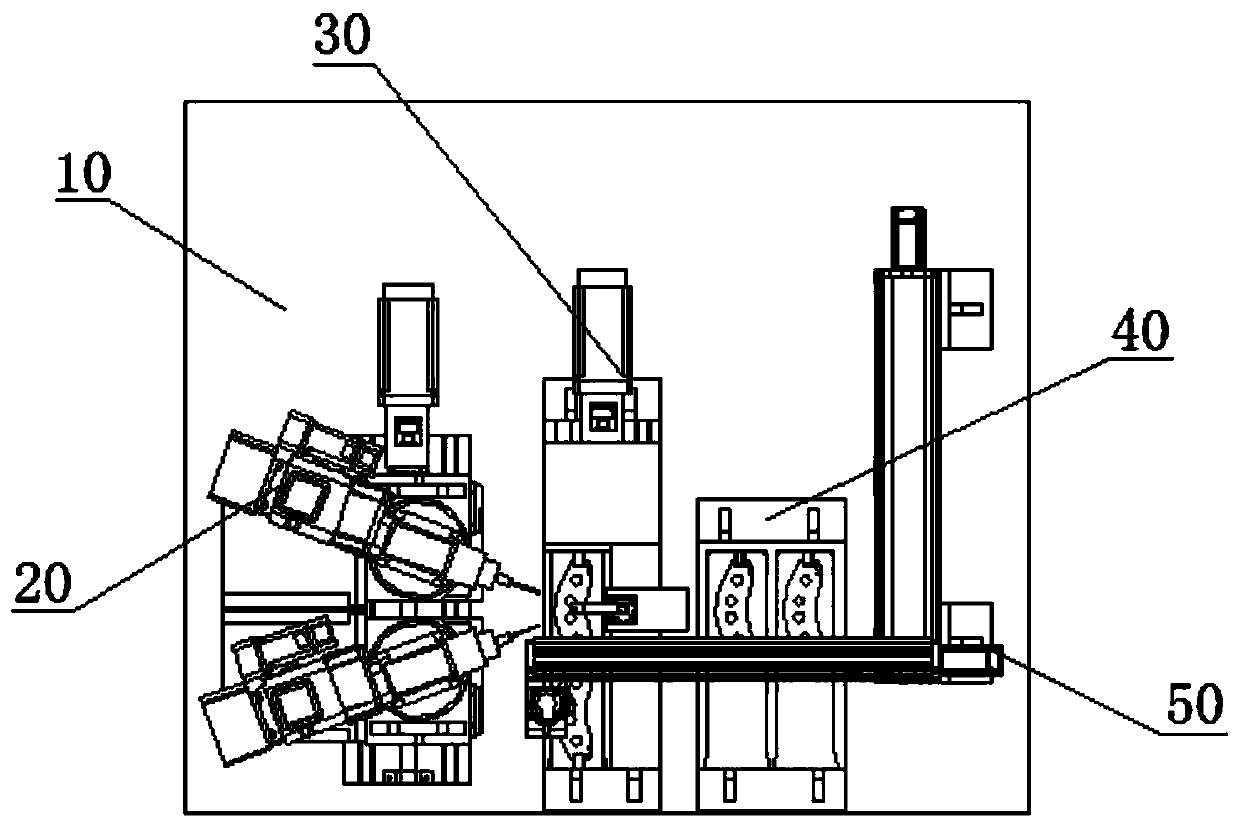

[0042] see Figure 1-Figure 10 , The brake pad steel back fully automatic CNC drilling machine provided by the present invention includes a frame assembly 10, a power head assembly 20, a station assembly 30, a bin assembly 40, a three-axis positioning robot arm 50 and an electric control system.

[0043] The frame assembly 10 is mainly used for installing and carrying other components, and can be designed and processed into a suitable structure and size according to actual conditions.

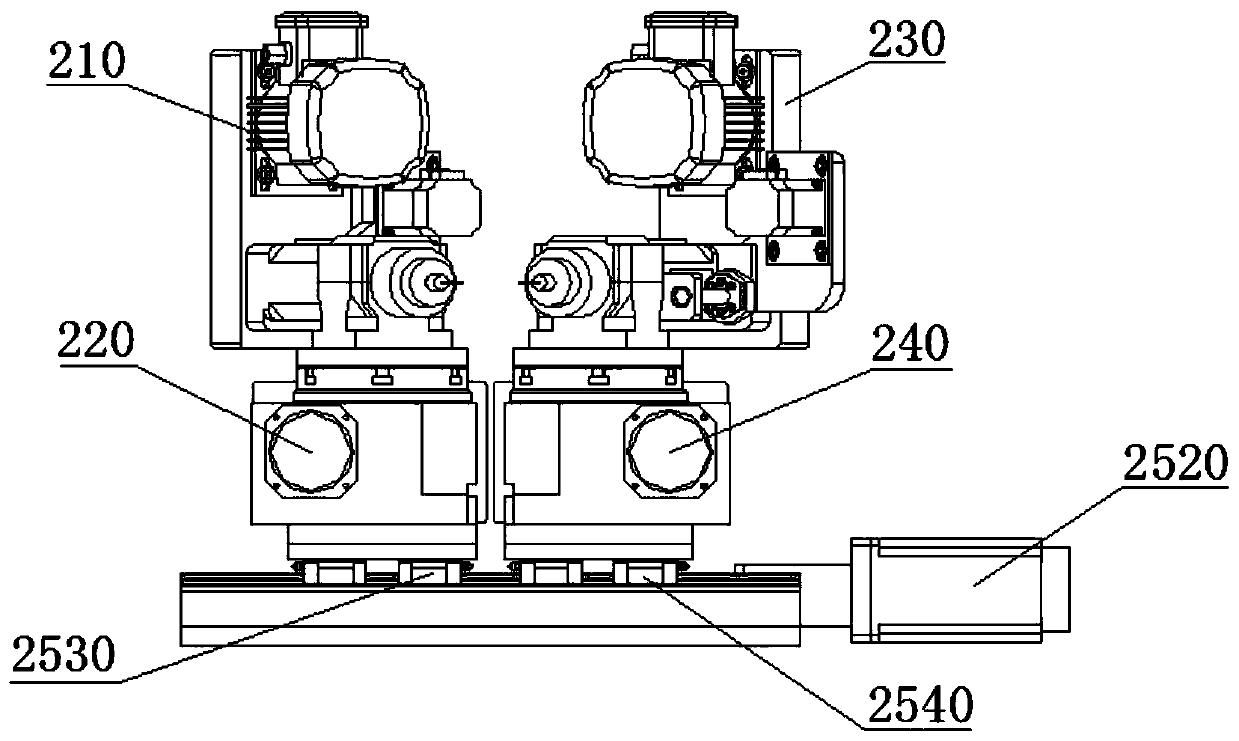

[0044] The power head assembly 20 is used to realize the automatic drilling of the steel back of the brake pad and the adjustment of the drilling angle and depth, which includes a front power head 210, a front electric indexing plate 220, a rear power head 230, and a rear electric indexing plate 240 And the two-way lead screw module 250, the two-way lead screw module 250 includes the two-way lead screw 2510, the two-way lead screw servo motor 2520 and the front slide table 2530 and the rear sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com