Fan-shaped slice one die double punch device and double punch technology thereof

A technology of one-die double punching and fan-shaped sheet, applied in the field of fan-shaped sheet, can solve the problems of low stamping efficiency and poor stamping effect, and achieve the effect of improving work efficiency, preventing shaking and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

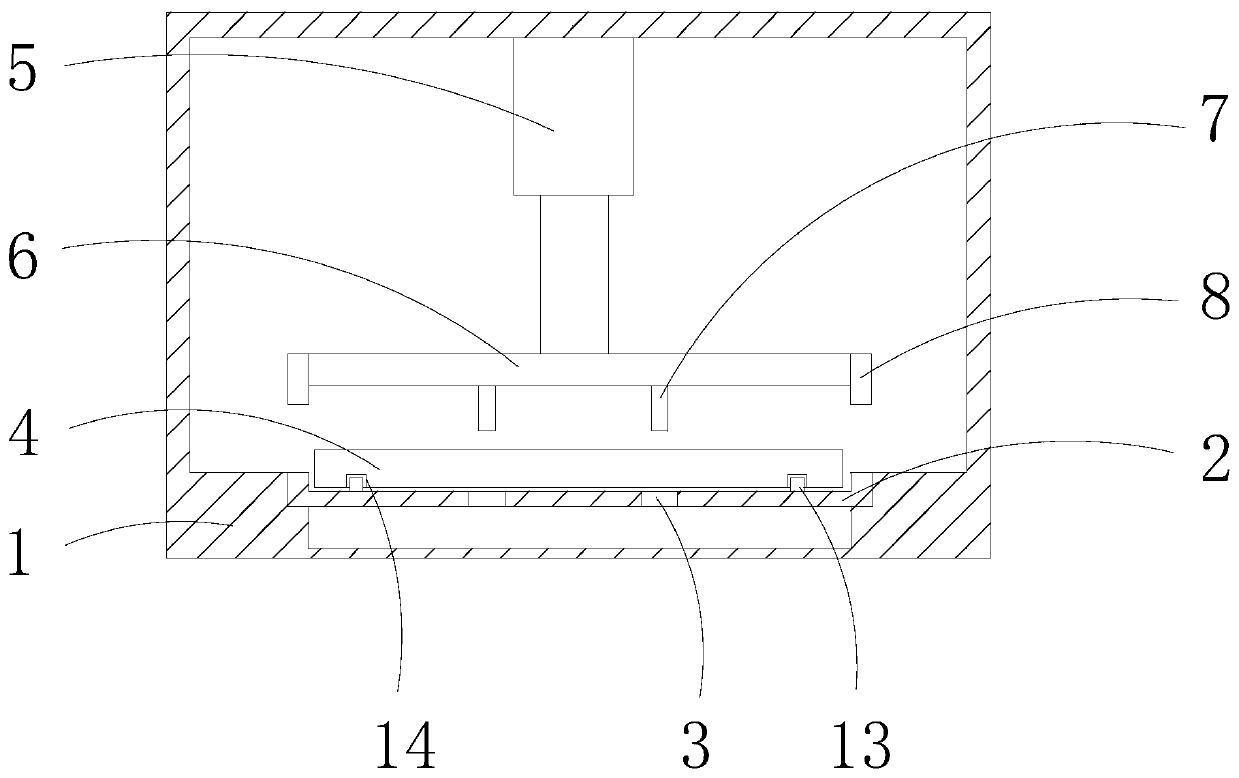

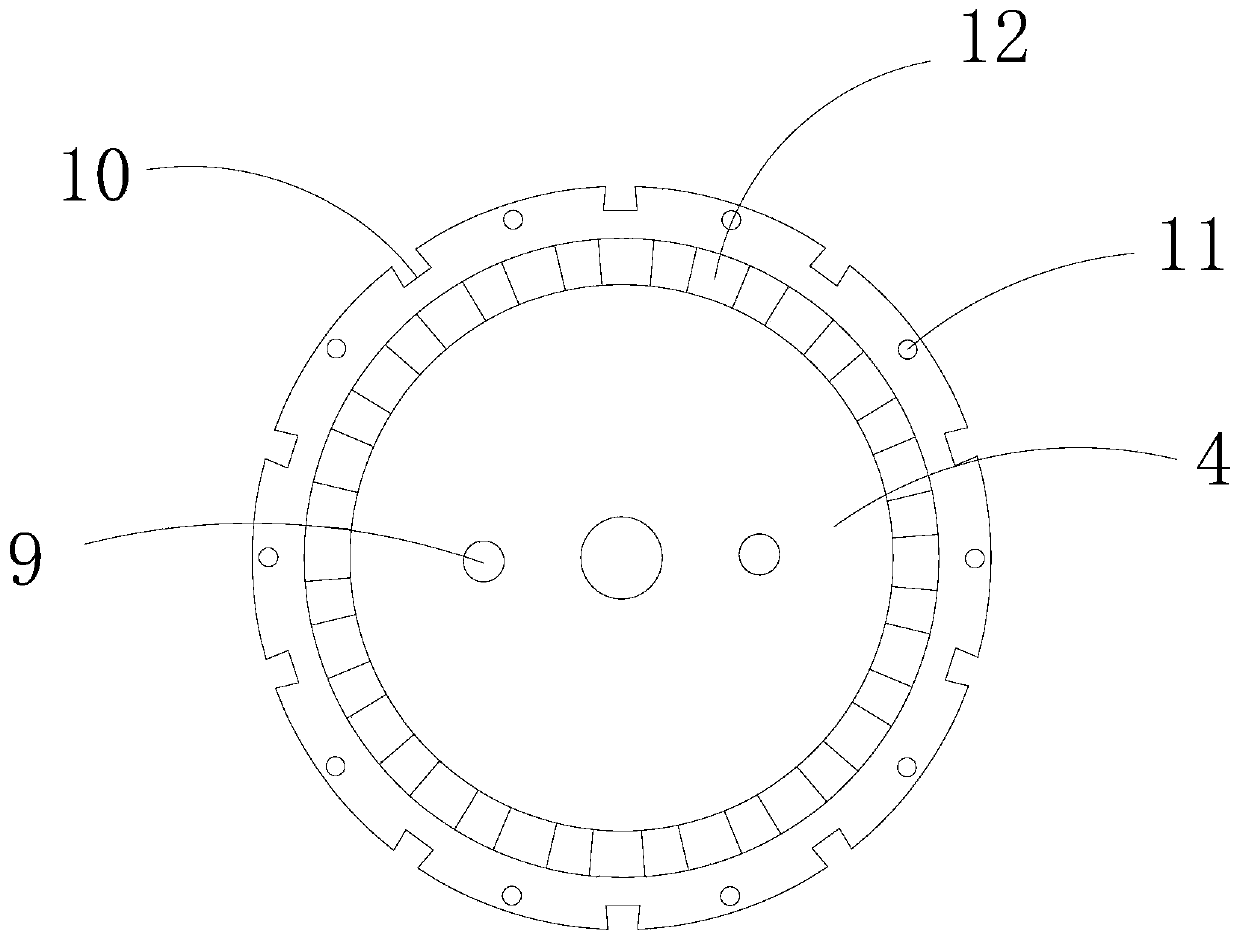

[0023] See Figure 1-Figure 2 , A fan-shaped one-mold double-punching device, comprising a main body 1, the bottom inner wall of the main body 1 is provided with a groove plate 2, the inside of the groove plate 2 is provided with a leakage port 3, and the top of the groove plate 2 is provided with a fan plate 4. The top inner wall of the main body 1 is fixedly connected with a pressure cylinder 5, the bottom of the pressure cylinder 5 is fixedly connected with a punching plate 6, the bottom of the punching plate 6 is fixedly connected with a punching head 7, and both ends of the punching plate 6 are fixedly connected with a limit plate 8. , One side of the sector piece 4 is provided with a punching hole 9, one side of the sector piece 4 is provided with a heat dissipation groove 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com