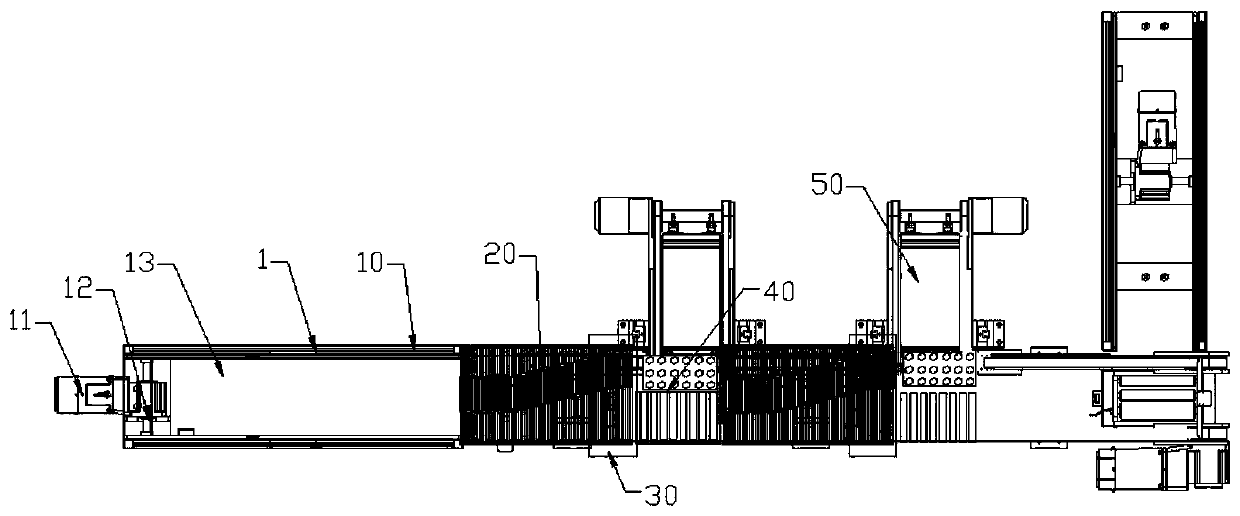

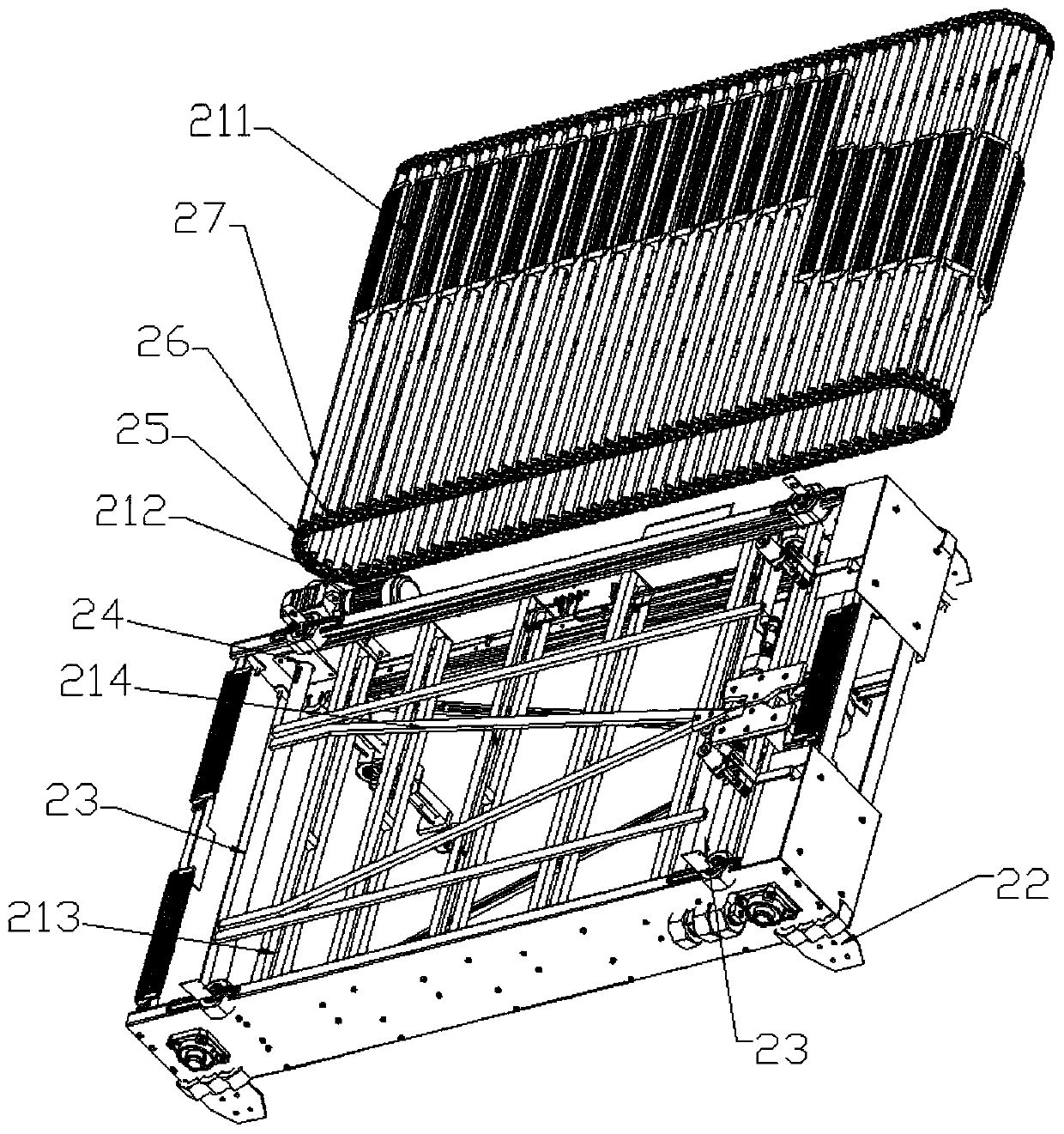

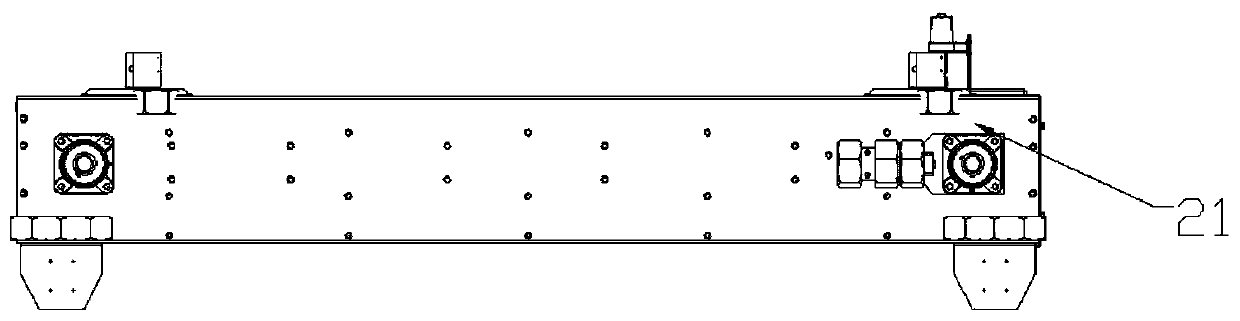

Distribution sorting system and sorting method for cartons of various sizes

A sorting system and carton technology, applied in chemical instruments and methods, grading, solid separation, etc., can solve the problems of slow sorting process, can not meet the palletizing requirements of the palletizing line, etc., achieve fast response speed, accurate positioning, The effect of reducing labor and labor management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In the following description, numerous specific details are given in order to provide a more thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without one or more of these details. In other examples, some technical features known in the art are not described in order to avoid confusion with the present invention.

[0040] The applicant found that most of the existing sorting systems use the model of visual sorting system to identify the size and shape of static items, so as to screen out the items that can be sorted by the sorting robot, so the existing sorting devices can only Suitable for static sorting of single items. When cartons of various sizes and specifications are dynamically advancing on the transportation line, the existing sorting device cannot respond quickly and meet the batch sorting of cartons of various specifications on the production line or logistics ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com