Combined shoe with zipper and production process thereof

A production process and zipper technology, applied in the field of shoes, can solve the problems of high production cost, large amount of raw materials used, separation, etc., and achieve the effect of enhancing novelty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

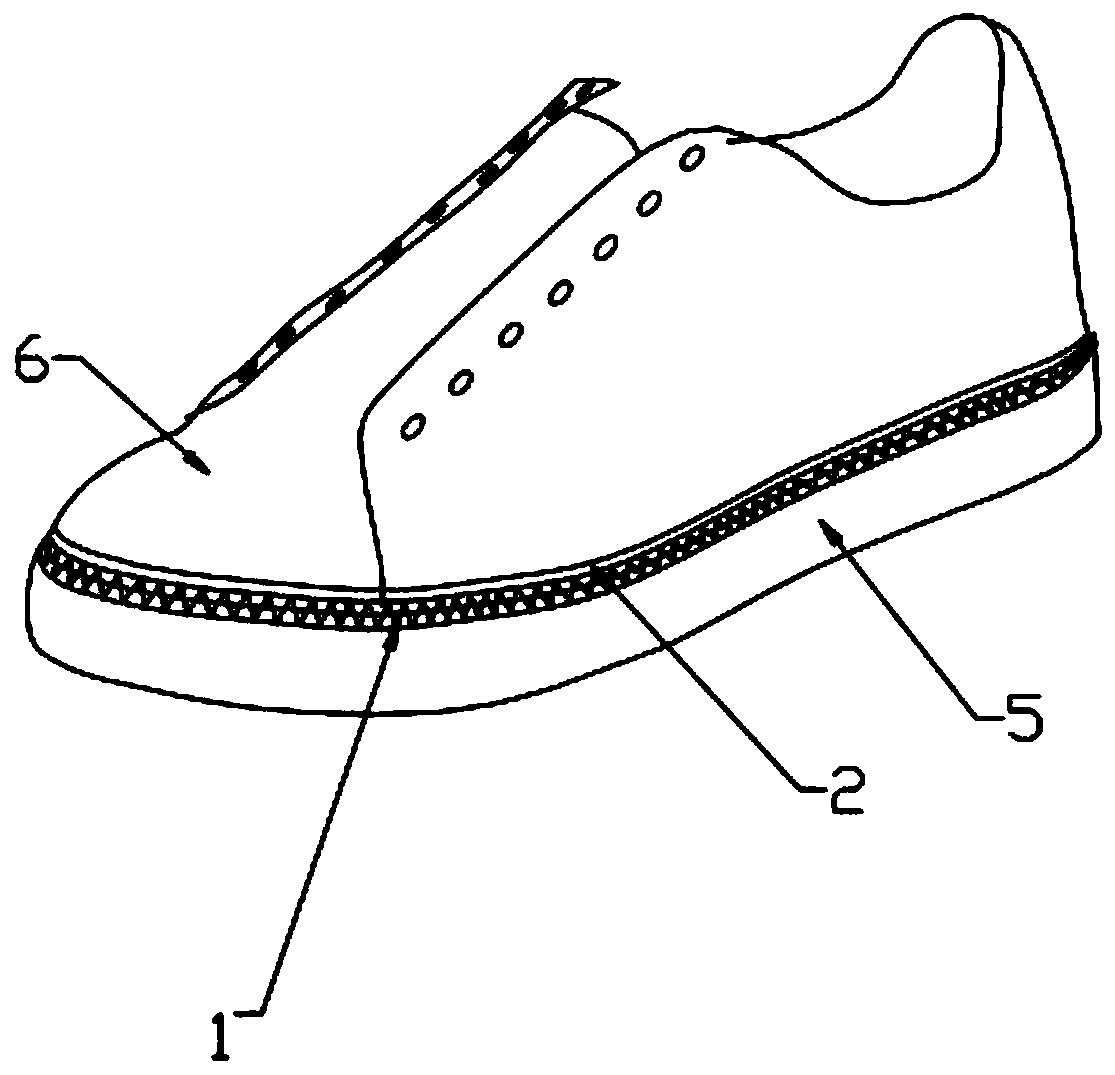

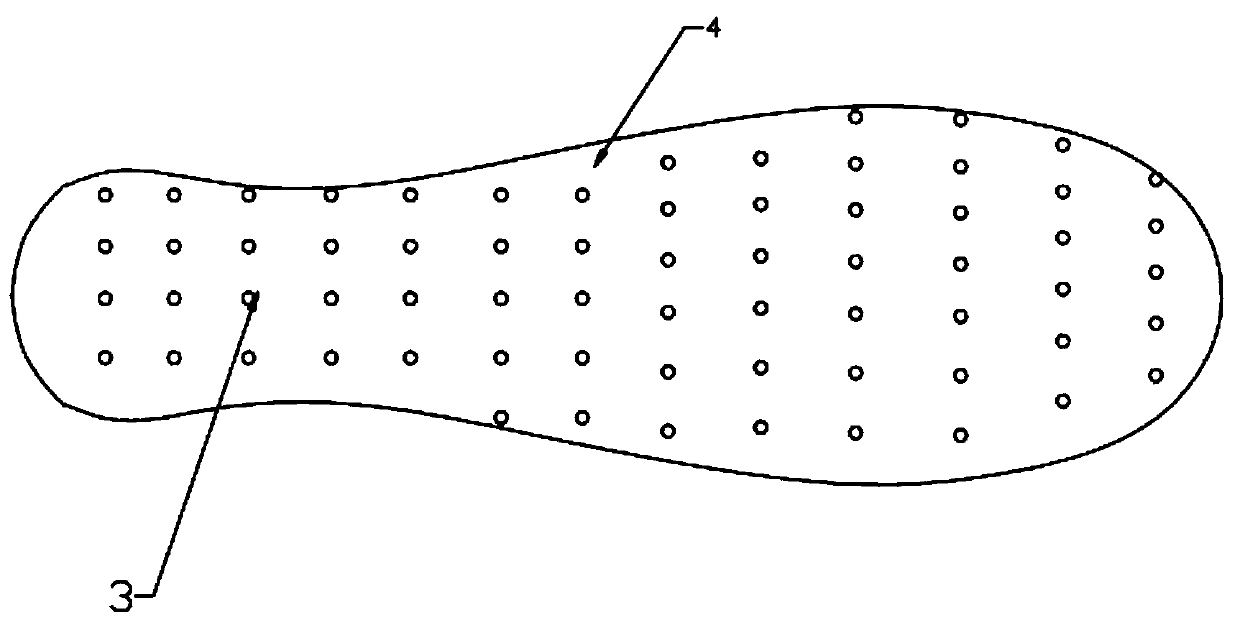

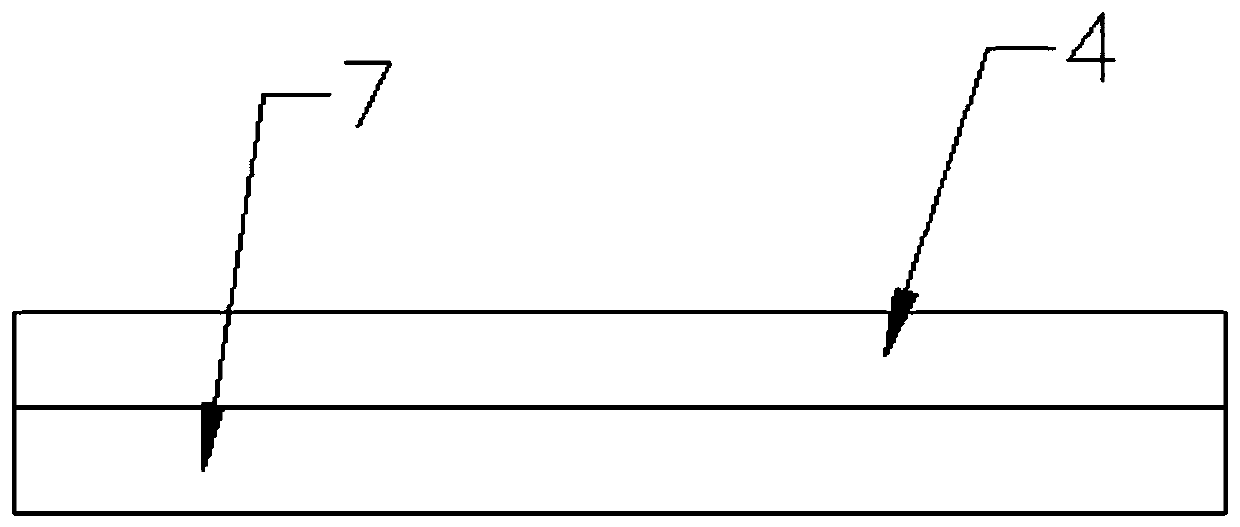

[0023] Embodiment 1: as Figure 1 to Figure 4 A combination shoe with a zipper 1 and its production process shown include a shoe body 6 and a sole 5, and it is characterized in that the bottom of the sole 5 and the upper edge of the sole 5 are provided with a matching zipper 1, so The outer edge of the sole 5 is provided with a rib 2, and the bottom of the shoe body 6 is provided with a lining layer 4;

[0024] The production process of the zipper 1 combined shoe includes the following steps: brush the inner side of the shoe body 6 (vamp) with white latex, put it into a sterilizing oven and bake it for about five minutes;

[0025] Brush a circle of white latex on the edge of the lining layer 4, put it in a sterilizing oven, and bake for about five minutes;

[0026] Take out the shoe pegs, put the shoe body 6 into the upper part of the shoe pegs, take out the lining layer 4 and put it into the bottom of the shoe pegs, and use the front upper machine to shape the upper of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com