Synchronous reluctance motor

A synchronous reluctance motor, the same technology, applied in synchronous machines, magnetic circuits, electromechanical devices, etc., can solve the problem of difficulty in designing torque ripple suppression means, achieve torque ripple suppression, reduce rotational noise, and improve motor performance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

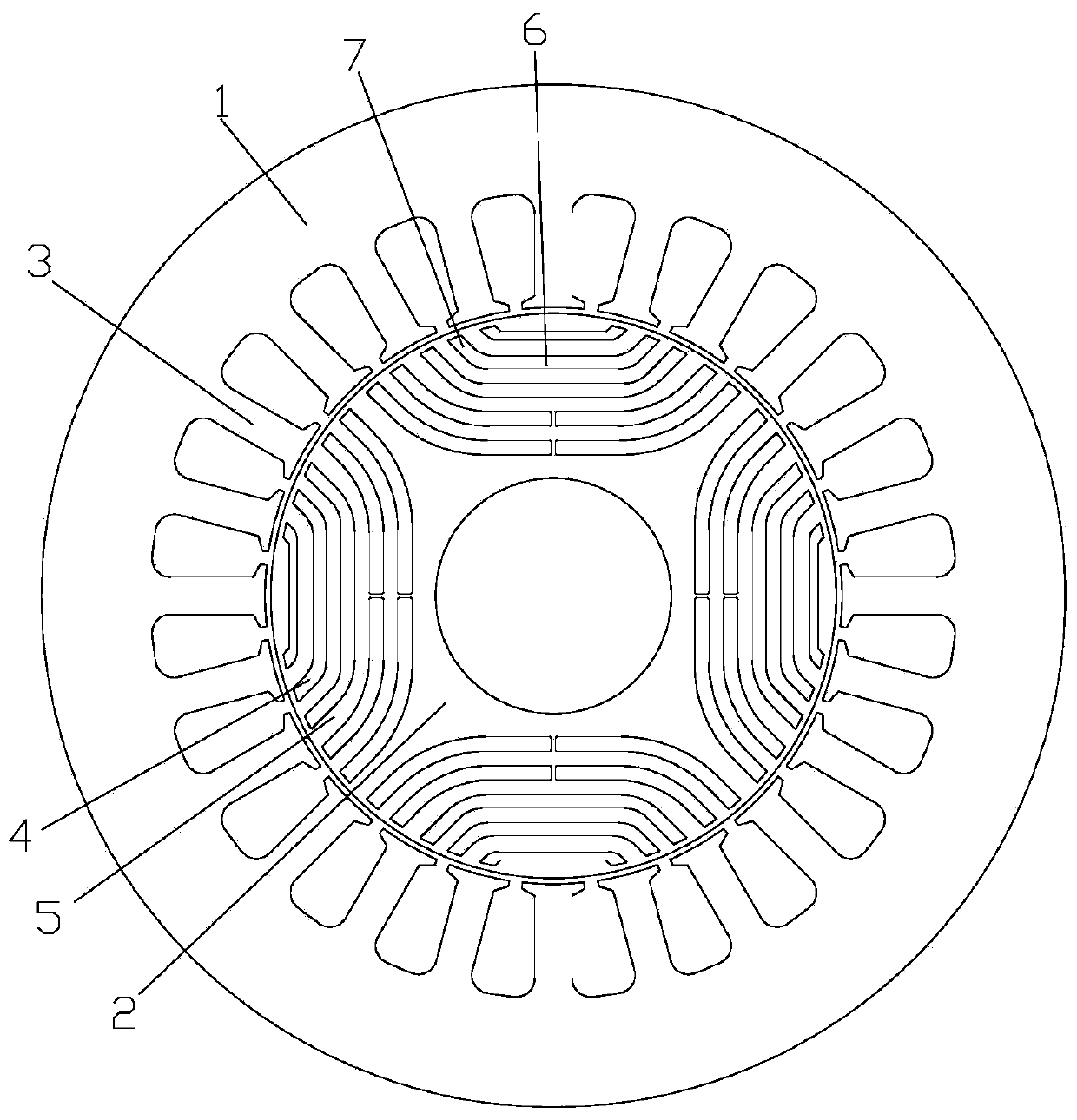

[0026] see in conjunction Figure 1 to Figure 6 As shown, according to the embodiment of the present application, the synchronous reluctance motor includes a stator core 1 and a rotor core 2, the stator core 1 includes stator teeth 3, and the rotor core 2 includes a plurality of magnetic barrier groups arranged in the circumferential direction , each magnetic barrier group includes a plurality of magnetic flux barriers 4 arranged at intervals in the radial direction, and a magnetic conduction channel 5 is formed between adjacent magnetic flux barriers 4 under the same pole, wherein the number of stator teeth N s , The number of magnetic flux barrier layers under each pole B s and the number of rotor poles 2p have the following relationship: N s / 2p=B s +1.

[0027] The number of stator teeth, the number of layers of magnetic flux barriers and the number of rotor poles are related to each other. This relationship affects the performance of the motor. This application uses th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com