Safe treatment method for fly ash

A technology for safe disposal of fly ash, applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of limited use and high price, and achieve the effects of reduced processing cost, short processing time and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

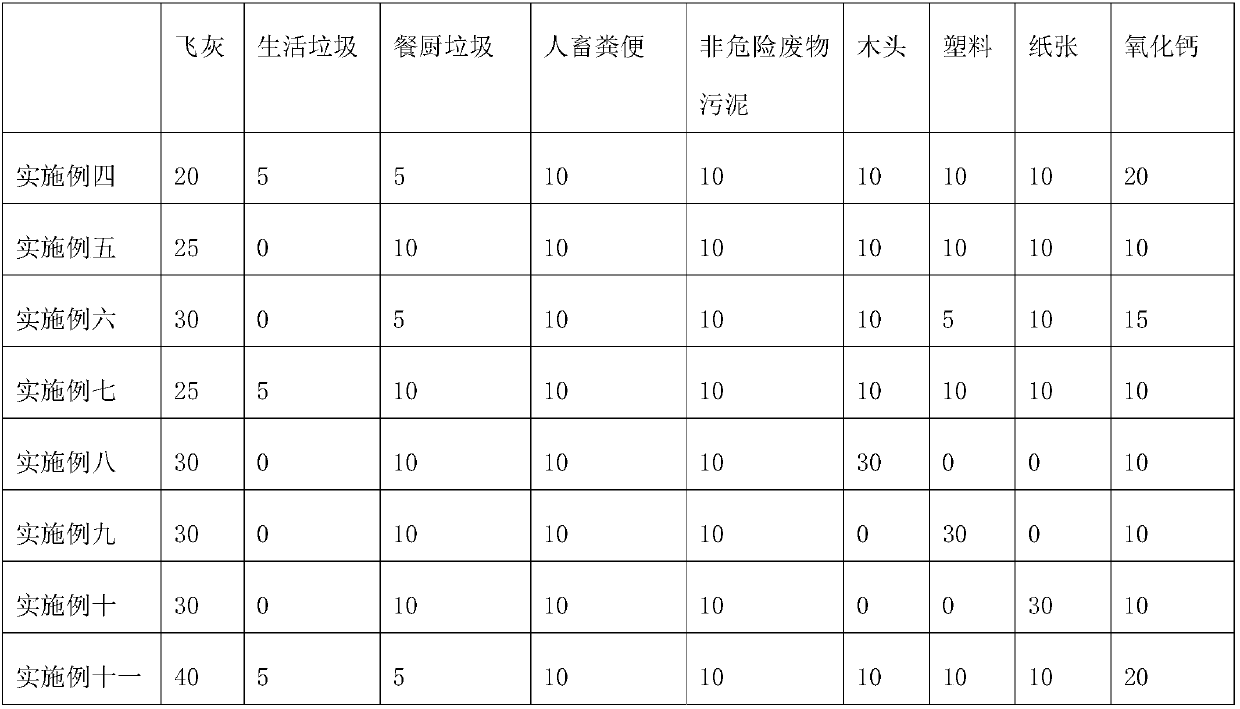

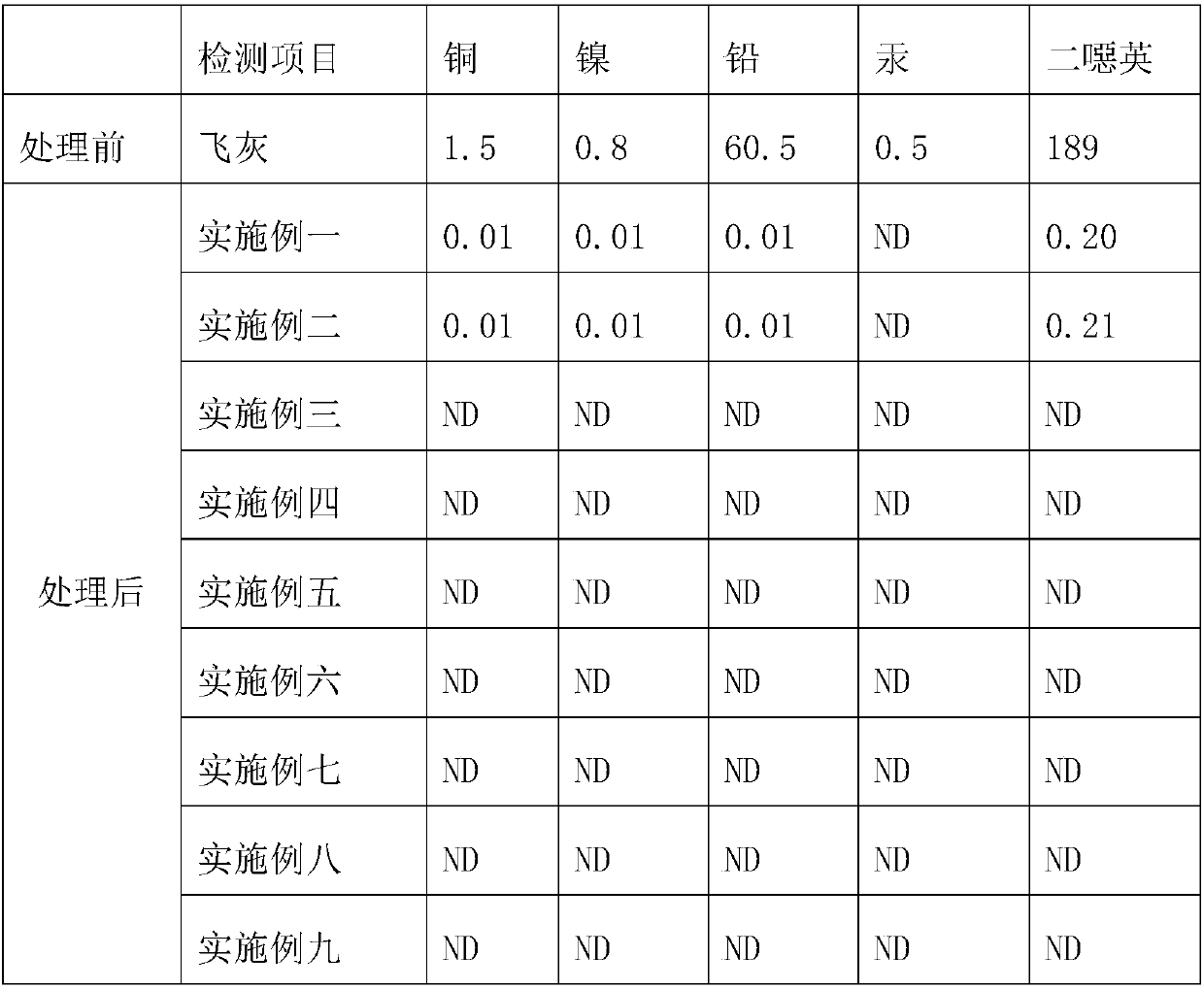

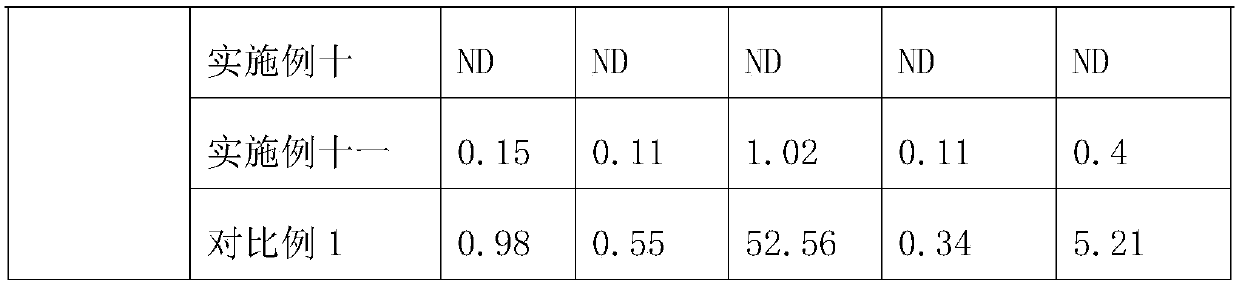

Examples

Embodiment 1

[0050] A method for safely handling fly ash, comprising the following steps:

[0051] (1) Deodorize and sterilize 10Kg of kitchen waste, 10Kg of domestic waste and 10Kg of human and animal manure;

[0052] (2) Sorting at least domestic waste and kitchen waste to remove plastic and rigid substances, and crushing and pre-processing each raw material after sorting, and the particle size of the crushed material is below 50mm;

[0053] (3) 30Kg of fly ash is mixed with domestic garbage, kitchen waste and human and animal excrement, and finally 10Kg of calcium oxide is added to mix evenly to obtain a mixture;

[0054] (4) Add the mixture to the kneading device and knead at least once;

[0055] (5) Add the kneaded material to the molding equipment to form a molded body, and then dry the molded body;

[0056] (6) Incinerate the dried molded body in a furnace at a temperature of 1000-1600° C., and obtain a harmless product after sufficient combustion.

[0057] Wherein, the fly ash i...

Embodiment 2

[0060] A method for safely handling fly ash, comprising the following steps:

[0061] (1) Deodorize and sterilize a total of 10Kg of kitchen waste and domestic waste, 10Kg of non-hazardous waste sludge and 10Kg of human and animal manure;

[0062] (2) Sorting at least domestic waste and kitchen waste to remove plastic and rigid substances, and crushing and pre-processing each raw material after sorting, and the particle size of the crushed material is below 50mm;

[0063] (3) After mixing 30Kg of fly ash and non-hazardous waste sludge evenly, then add domestic garbage, kitchen waste and human and animal manure to it for mixing, and finally add 10Kg of calcium oxide and mix evenly to obtain a mixture;

[0064] (4) Add the mixture to the kneading device and knead at least once;

[0065] (5) Add the kneaded material to the molding equipment to form a molded body, and then dry the molded body;

[0066] (6) Incinerate the dried molded body in a furnace at a temperature of 1000-16...

Embodiment 3

[0072] A method for safely handling fly ash, comprising the following steps:

[0073] (1) Deodorize and sterilize a total of 10Kg of kitchen waste and domestic waste, 10Kg of non-hazardous waste sludge, and 10Kg of human and animal manure. and pine leaves are collected, pulverized, mixed, heated to 140°C, and the steamed high-temperature turpentine steam is passed from the bottom of the collection tank to the collection tanks of domestic garbage, kitchen waste, non-hazardous waste sludge and human and animal manure to remove them. Odor sterilization treatment, the treatment time for domestic waste, kitchen waste, non-hazardous waste sludge and human and animal manure is 24-28 hours, 32-34 hours, 32-42 hours and 42-48 hours respectively;

[0074] (2) Sorting at least domestic waste and kitchen waste, removing plastic and rigid substances, and crushing each raw material for pretreatment after sorting. The particle size of the crushed material is below 50mm, and its moisture cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com