A self-sealing manhole cover for underground engineering construction based on the principle of thermal evaporation

An underground engineering and thermal evaporation technology, which is applied in infrastructure engineering, water conservancy engineering, artificial islands, etc., can solve problems such as poor drainage, small stones or mud blockages in inspection well covers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

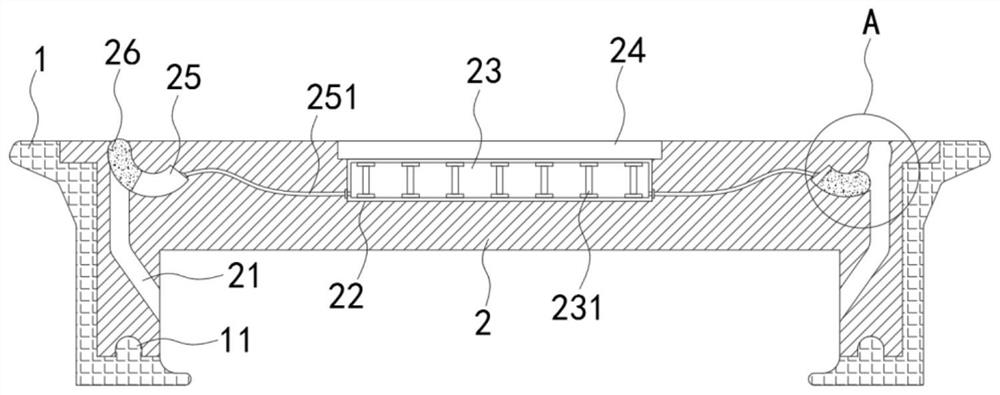

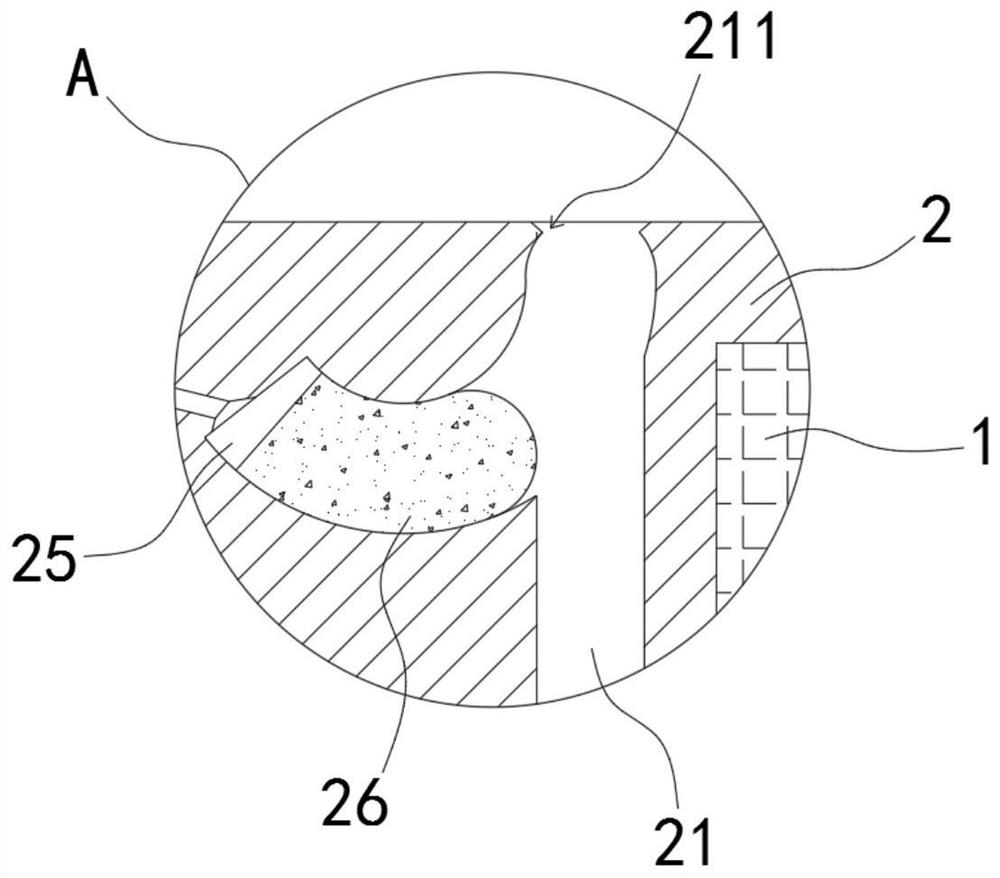

[0030] Such as Figure 1-3 As shown, a self-sealing manhole cover for underground engineering construction based on the principle of thermal evaporation includes a base 1 and a cover body 2. The lower edge of the base 1 extends inward to form a support seat, and the upper edge extends outward to form a snap seat. Specifically, the lower end of the cover body 2 is provided with an annular groove, and the support seat of the base 1 is provided with a limit ring 11 corresponding to the annular groove; the edge of the cover body 2 fits the base 1 so that the base 1 and the cover The degree of fit between body 2 is higher, and under load-bearing conditions, the two are less likely to deviate, which improves stability.

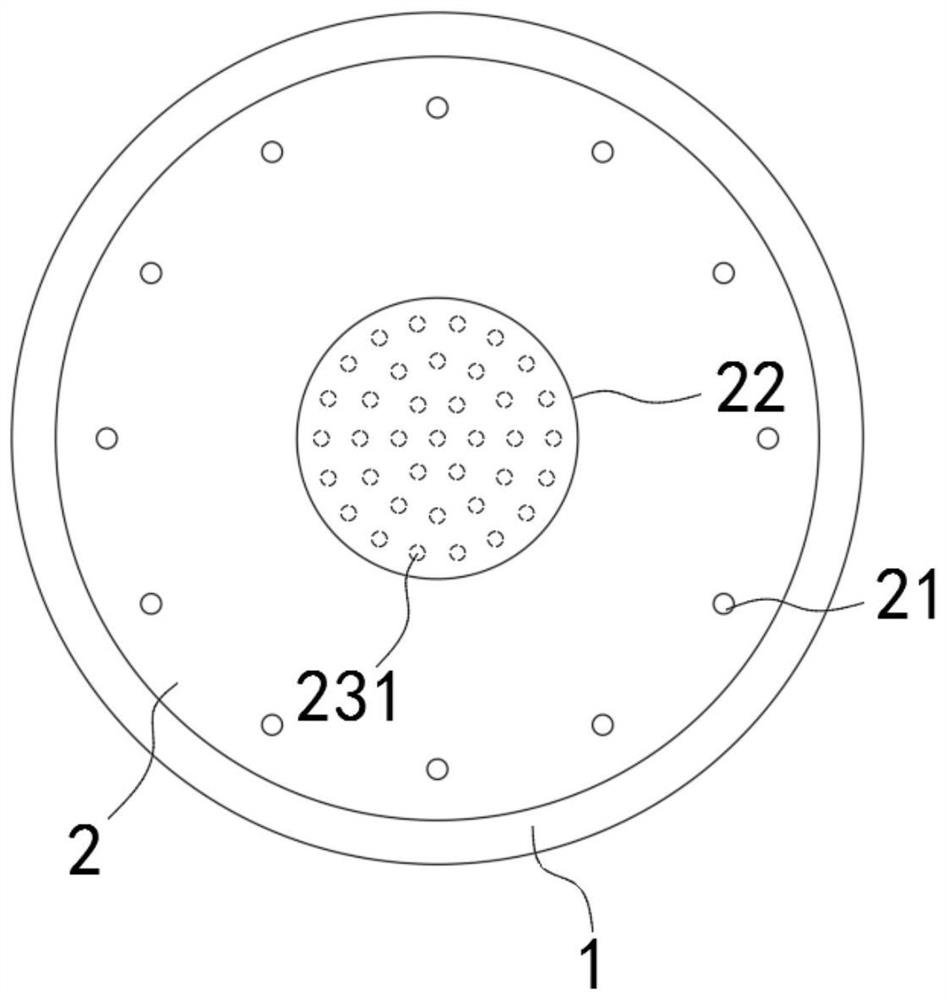

[0031] The cover body 2 is provided with: a plurality of drain holes 21, the upper end of the drain hole 21 is arranged on the upper surface of the cover body 2, the lower end of the drain hole 21 is arranged on the inner side wall of the lower end of the cover body...

Embodiment 2

[0041] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the heat conduction plate 24 includes a spherical plate 241 and an annular reflector 242, the spherical plate 241 is fixedly connected to the center of the liquid storage box 23, and the annular reflector 242 is fixedly connected to the Outside the spherical plate 241 , the upper surface of the annular reflector 242 is a concave surface with a focus on the spherical plate 241 .

[0042] In this embodiment, the annular reflector 242 focuses on the spherical panel 241 after receiving light, which can make the spherical panel 241 heat up rapidly, making the evaporating liquid easier to be heated and vaporized; The downward depression makes it easier to collect rainwater and make the evaporative liquid more likely to be liquefied when it is cold. Therefore, the sensitivity of the entire device to the weather is greatly improved, so that it has a faster response speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com