Treatment device and treatment method for aquaculture wastewater

A technology for wastewater treatment and aquaculture, which is applied in water/sewage treatment, animal husbandry wastewater treatment, light water/sewage treatment, etc. Reduce the labor intensity of manual operation, realize mechanized operation, and improve the effect of breeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

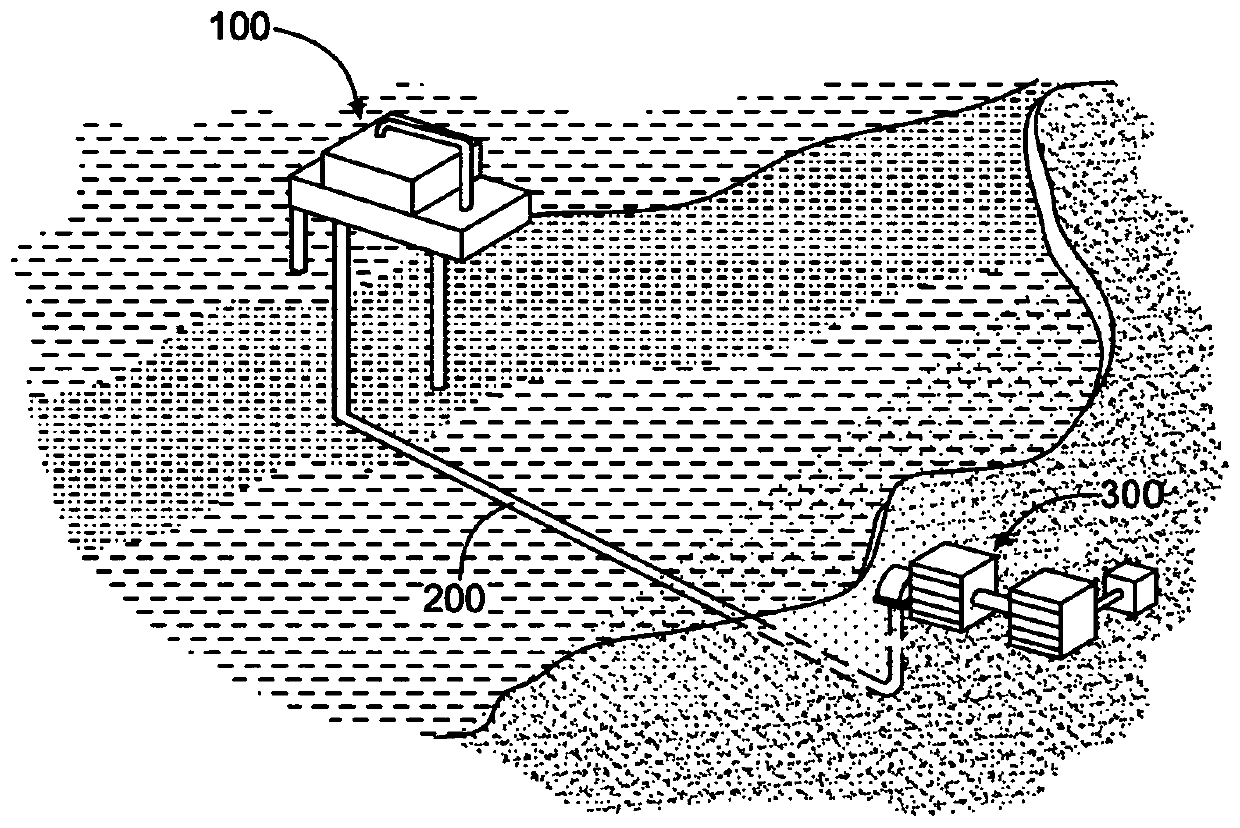

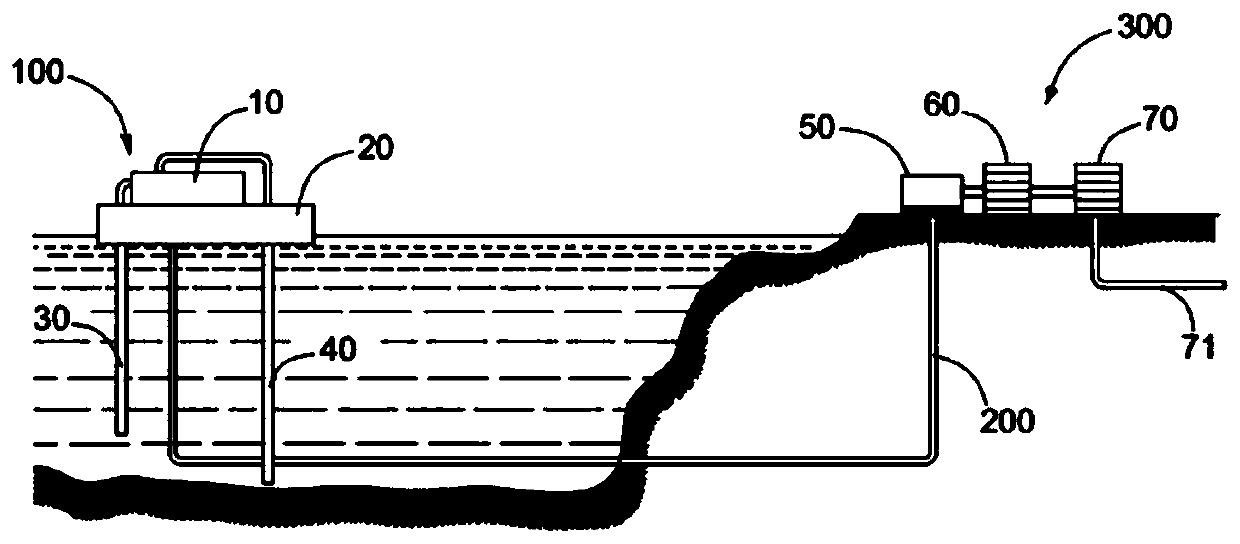

[0040] see Figure 1-7 As shown, the aquaculture wastewater treatment device includes:

[0041] The waste collection assembly 100 is arranged above the aquaculture water body,

[0042] The land-based water purification unit 300 is located on the ground, and the land-based water purification unit 300 is connected to the waste collection unit 100 through the sewage pipe 200,

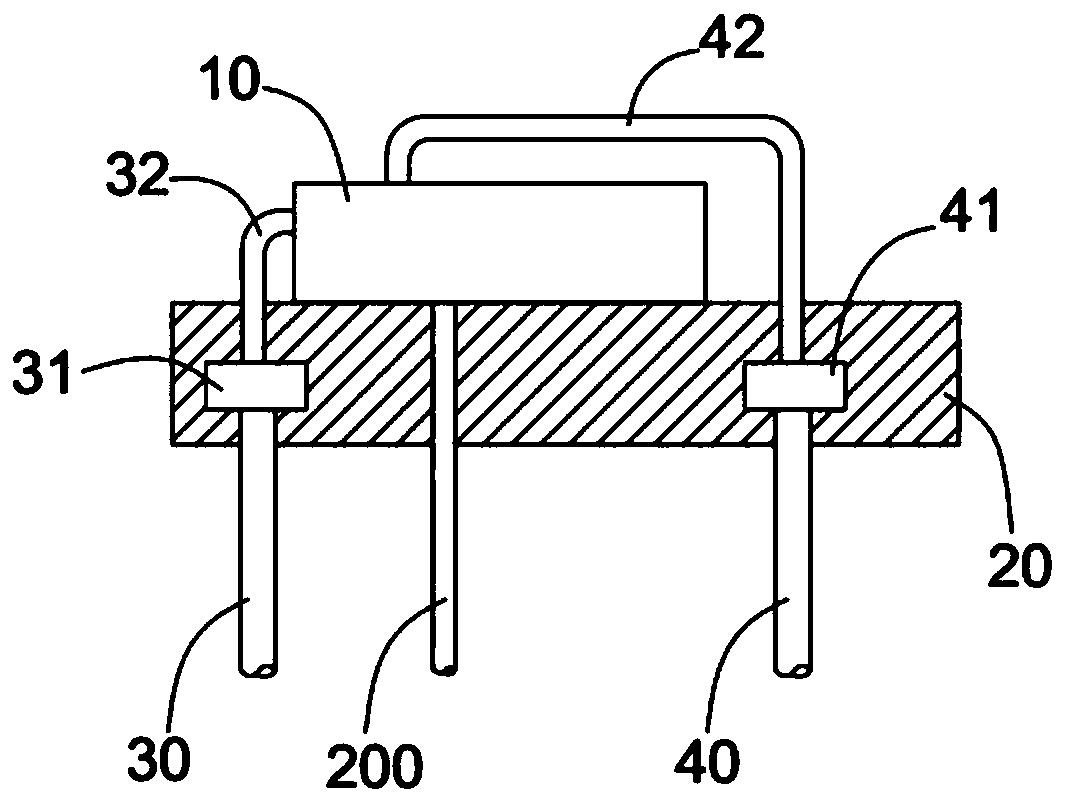

[0043] Wherein, the waste collection assembly 100 includes a floating body 20, a separation box 10 is arranged on the floating body 20, a first mud pump 41 and a second mud pump 31 are respectively arranged in the floating body 20, and the first mud pump 41 is connected with a second extraction pipe 40 Extract the waste at the bottom of the culture water, the second mud pump 31 is connected with the first extraction pipe 30, the length of the first extraction pipe 30 is shorter than the second extraction pipe 40, the first mud pump 41 and the second mud pump 31 are respectively connected with the separati...

Embodiment 2

[0058] A kind of aquaculture wastewater treatment method:

[0059] The second extraction pipe 40 and the first extraction pipe 30 of different lengths are used to extract the wastes at different heights of the bottom layer of the aquaculture water respectively, and obtain the wastes of different water layers;

[0060] Through the first mud pump 41 and the second mud pump 31, the obtained waste and water mixture are sent into the separation tank 10 to perform solid-liquid separation on the extracted waste, and the separated solid is intercepted by the sieve plate 14, and the water is separated for water filtration For treatment, the water body falls to the space at the bottom of the sieve plate 14, and the sewage pipe 200 sends the separated sewage to the land-based water purification module 300 on the bottom surface for water filtration treatment;

[0061] After the sewage enters the land-based water purification unit 300, it first enters the water filter tank 60 for water fil...

Embodiment 3

[0064] Sink test:

[0065] Utilize the indoor water tank, lay sediment at the bottom of the water, utilize the device of example 1 of the present invention to carry out sediment extraction in the water tank, as experimental group 1, observe the process of sediment resuspension, and remove the first extraction pipe 30 of embodiment 1 Then carry out the sediment extraction work again to observe the sediment suspension process, as the experimental group 2.

[0066] The water tank used in the test is 10 meters long, 0.5 meters wide, and 1 meter high. The sediment at the bottom of the water tank is about 4 meters long, 0.5 meters wide, and 0.35 meters high. The particle diameter of the sediment is about 0.036mm, of which the particle size of less than 0.02mm accounts for about 25%. After the sediment in the tank is placed, it needs to be left for 5 days and then slowly injected with fresh water.

[0067] The distance between the second extraction pipe 40 and the sediment of the ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com