All gear stepless automatic transmission and speed ratio active control system

It is an active control system and automatic speed change technology, which is applied in the direction of gear transmission, belt/chain/gear, transmission device, etc. It can solve the problems of small range of speed ratio change, complicated shifting operation, and poor adaptability to the use environment. Large ratio change range, high efficiency, and the effect of realizing stepless automatic transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

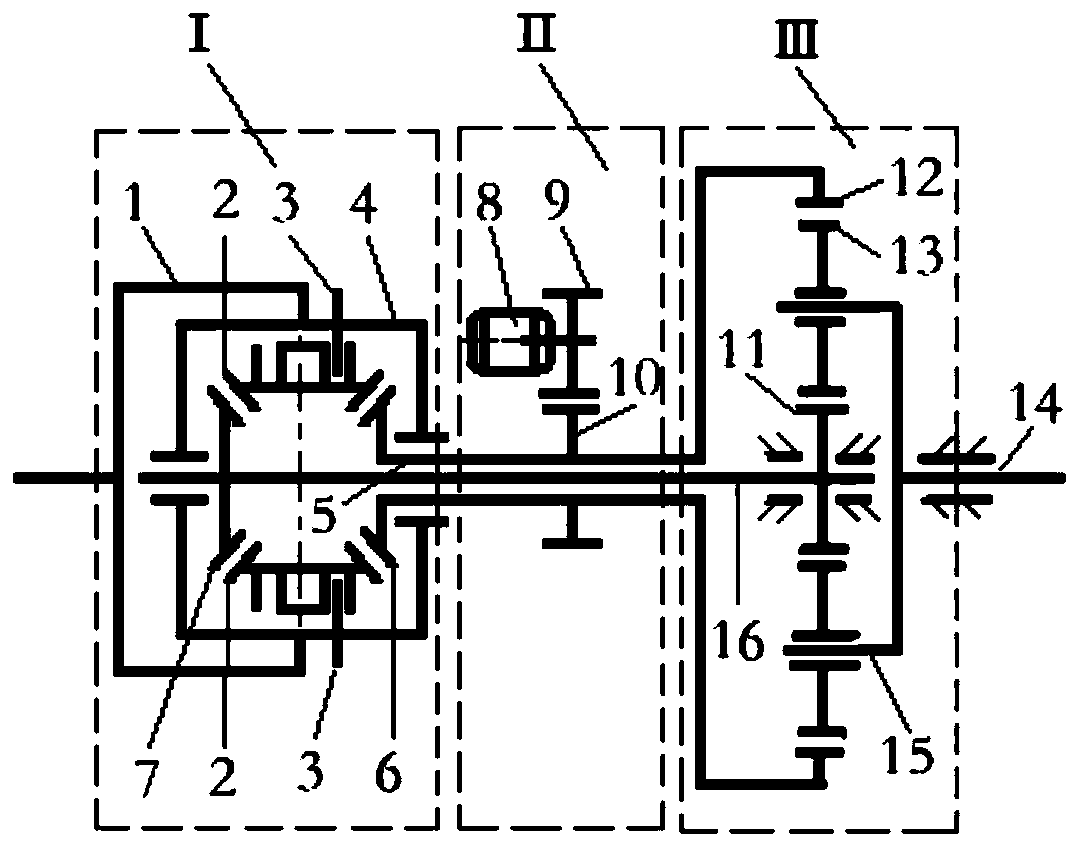

[0045] For the specific structure of the all-gear stepless automatic transmission and speed ratio active control system implemented according to the present invention, see figure 1 . The all-gear continuously variable automatic transmission and active ratio control system includes at least three parts connected in sequence: differential mechanism I for proportional torque distribution, active ratio control mechanism II, and planetary gear mechanism III.

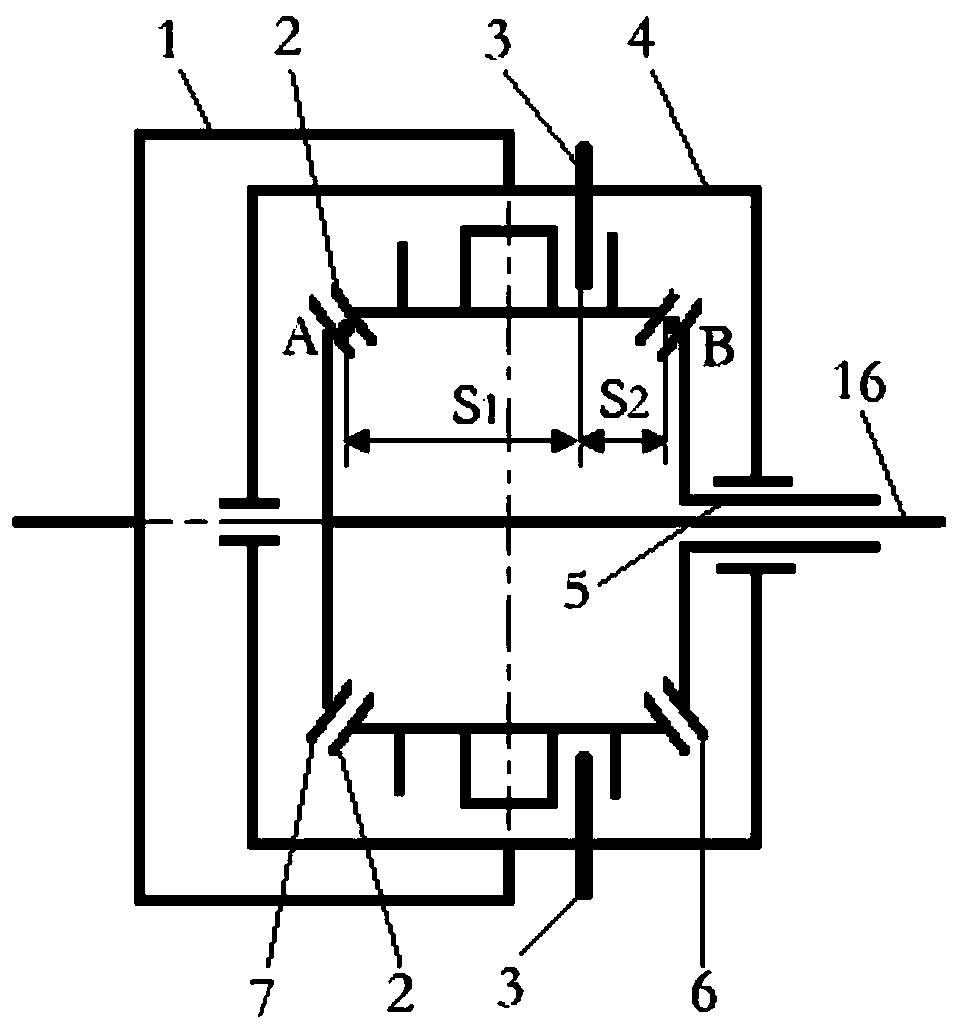

[0046] Among them, the differential mechanism I and the planetary gear mechanism III, which distribute the torque in proportion, together constitute the continuously variable automatic transmission device. The differential mechanism I that distributes torque in proportion includes two differential bevel gears at the output end of power and motion: the first differential bevel gear 6 and the second differential bevel gear 7; the first differential bevel gear 6 passes through the first differential The speed bevel gear shaft 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com