A water retaining cofferdam structure and its construction technology

A construction technique and cofferdam technology, applied in infrastructure engineering, construction, etc., can solve problems affecting construction progress, troubles, etc., and achieve the effect of improving stability and reducing the possibility of rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

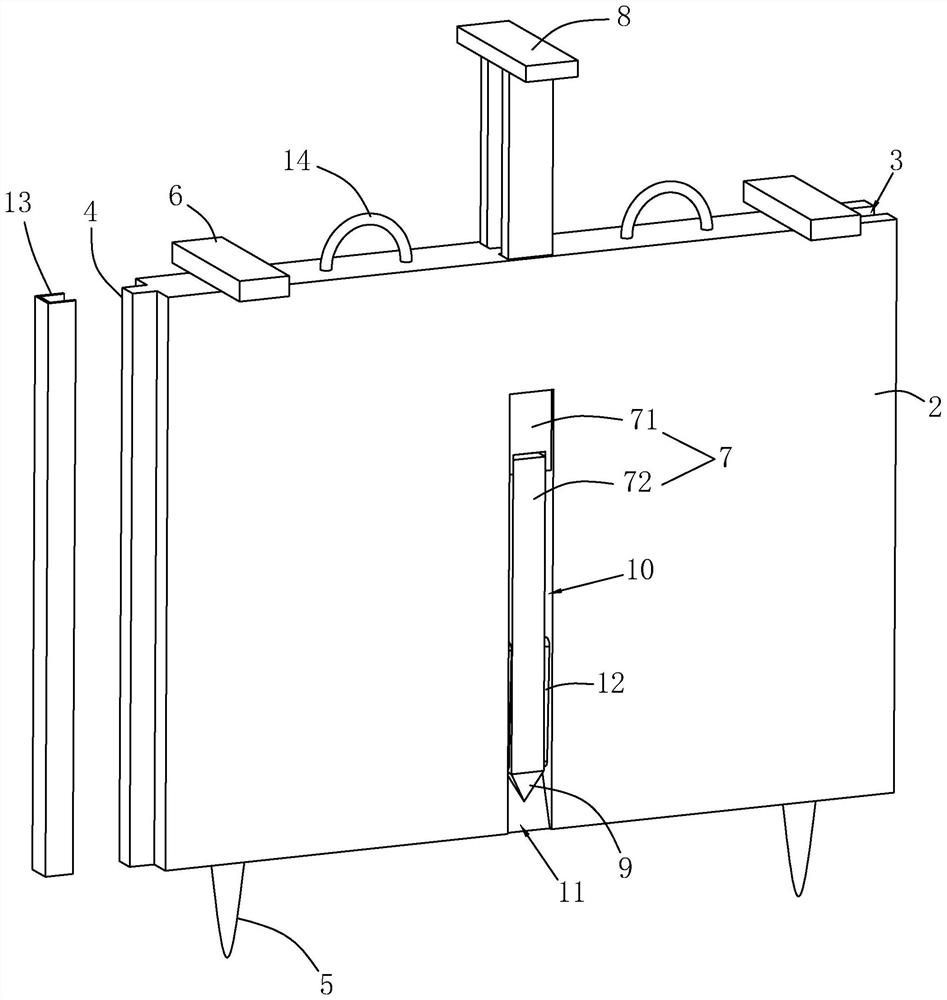

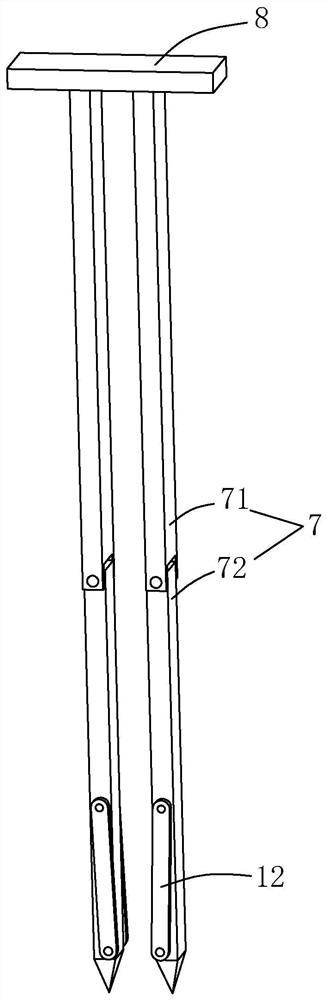

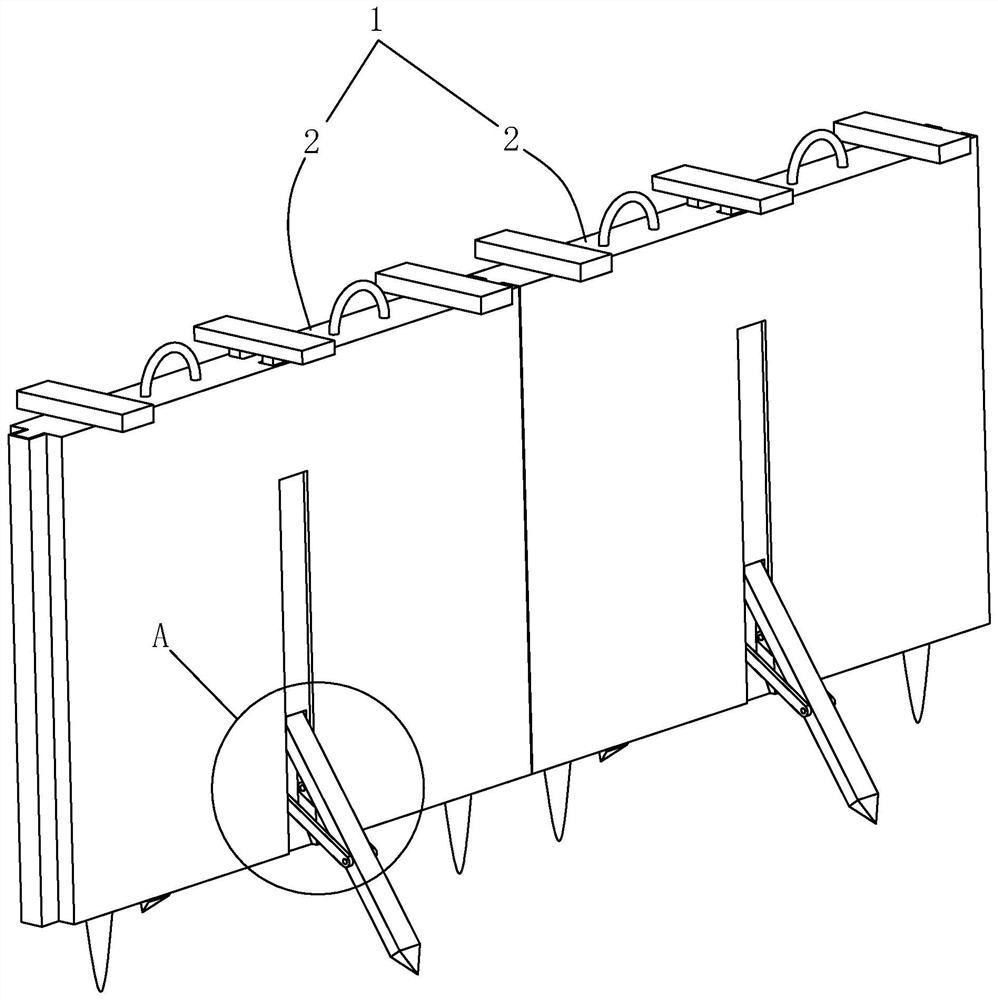

[0041] combine figure 1 and image 3 , a water-retaining cofferdam structure, comprising a water-retaining cofferdam 1 arranged along the movement direction of a river. The water retaining cofferdam 1 includes a plurality of water retaining boards 2, and the water retaining cofferdam 1 formed by splicing the plurality of water retaining boards 2 is arc-shaped. The upper end of water retaining plate 2 is welded with two handles 14, is convenient to it is hoisted. The water retaining plate 2 is provided with slots 3 and welded blocks 4 on both sides of the water retaining plate 2 along the installation direction toward the river bed. catch. Each block 4 is coated with a water-stop strip 13 at its edge along its length direction. After the slot 3 is engaged with the block 4, the water-stop strip 13 expands when it encounters water, and the slot 3 and the block can be connected together. The installation gap of 4 is filled to reduce the inflow of river water from the gap betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com