Rapid construction method for U-shaped groove crossing existing culvert

A construction method and technology of U-shaped grooves, which are applied in excavation, infrastructure engineering, roads, etc., can solve the problems of prolonging the construction period and prolonging the construction light period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

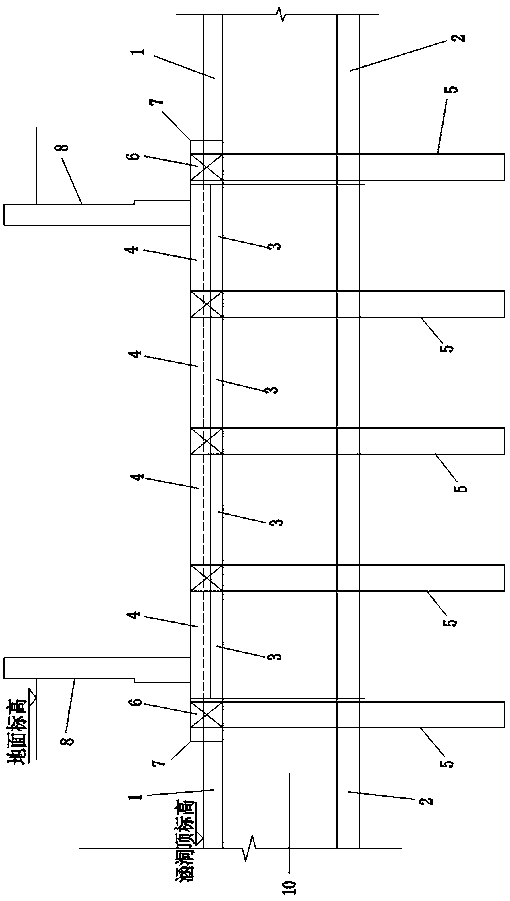

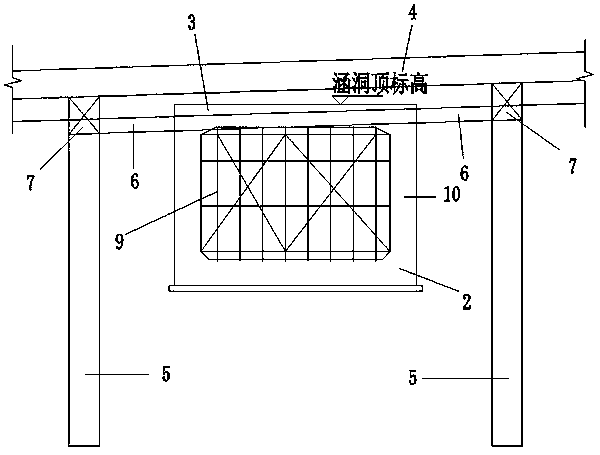

[0026] This embodiment provides a rapid construction method for the U-shaped groove of an existing culvert, which includes the following steps:

[0027] S1, according to the depth and position of the U-shaped groove foundation pit, adopt the traditional sloping excavation technology, first use sloping excavation, the earthwork will be excavated by vertical slope and flowing water, and horizontal layered sloping excavation, after the excavation is completed The slope bolts are set, and after the construction of the bolts is completed, the slopes are hung with nets and sprayed with concrete, and excavated to the bottom of the U-shaped groove foundation pit at one time;

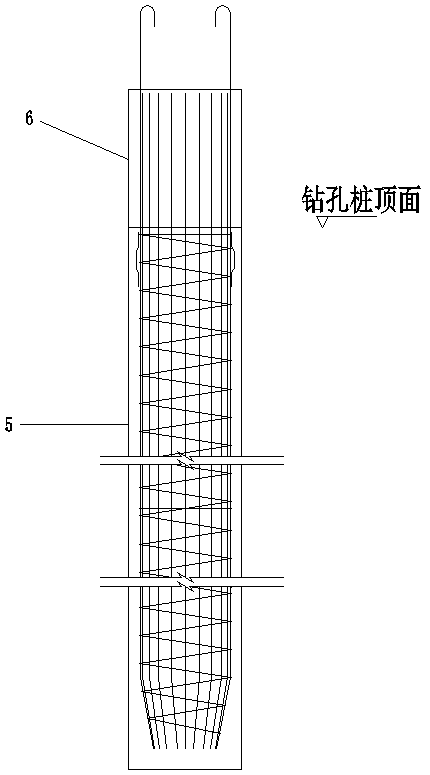

[0028] S2. After the U-shaped groove foundation pit is excavated to the specified elevation, support piles 5 shall be installed on both sides of the culvert. The distance between the support piles 5 and the side beams of the culvert shall not be less than 1 meter. The steel bars are reserved and anchored into th...

Embodiment 2

[0034] The entrance and exit line of Longdongzhuang Parking Lot of Jinan Rail Transit R3 Line is drawn from Mengjiazhuang Xiaolicheng, and is laid southward along Longding Avenue. 1736.151m, in which the top plate of the box culvert of the Daxin East tributary ditch conflicts with the bottom plate of the U-shaped trough in the open excavation section. The river branch ditches are responsible for the confluence of rainwater and flood diversion in the southern mountainous area, and the construction cannot be cut off. The drainage in the box culvert is continuous. The specific steps of adopting a rapid construction method for the U-shaped groove of an existing culvert spanning above are as follows.

[0035] S1, according to the depth and position of the U-shaped groove foundation pit, excavation by sloping is adopted first, the earthwork is excavated longitudinally by pulling the slope and running water, and the excavation is excavated by sloping horizontally in layers. The first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com