Environment-friendly treatment method based on printing and dyeing wastewater

A technology for the treatment of printing and dyeing wastewater and environmental protection, which is applied in the textile industry wastewater treatment, water/sewage treatment, neutralization water/sewage treatment, etc. Removal of problems such as poor effect, to achieve the effect of less investment, energy saving and consumption reduction, and improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

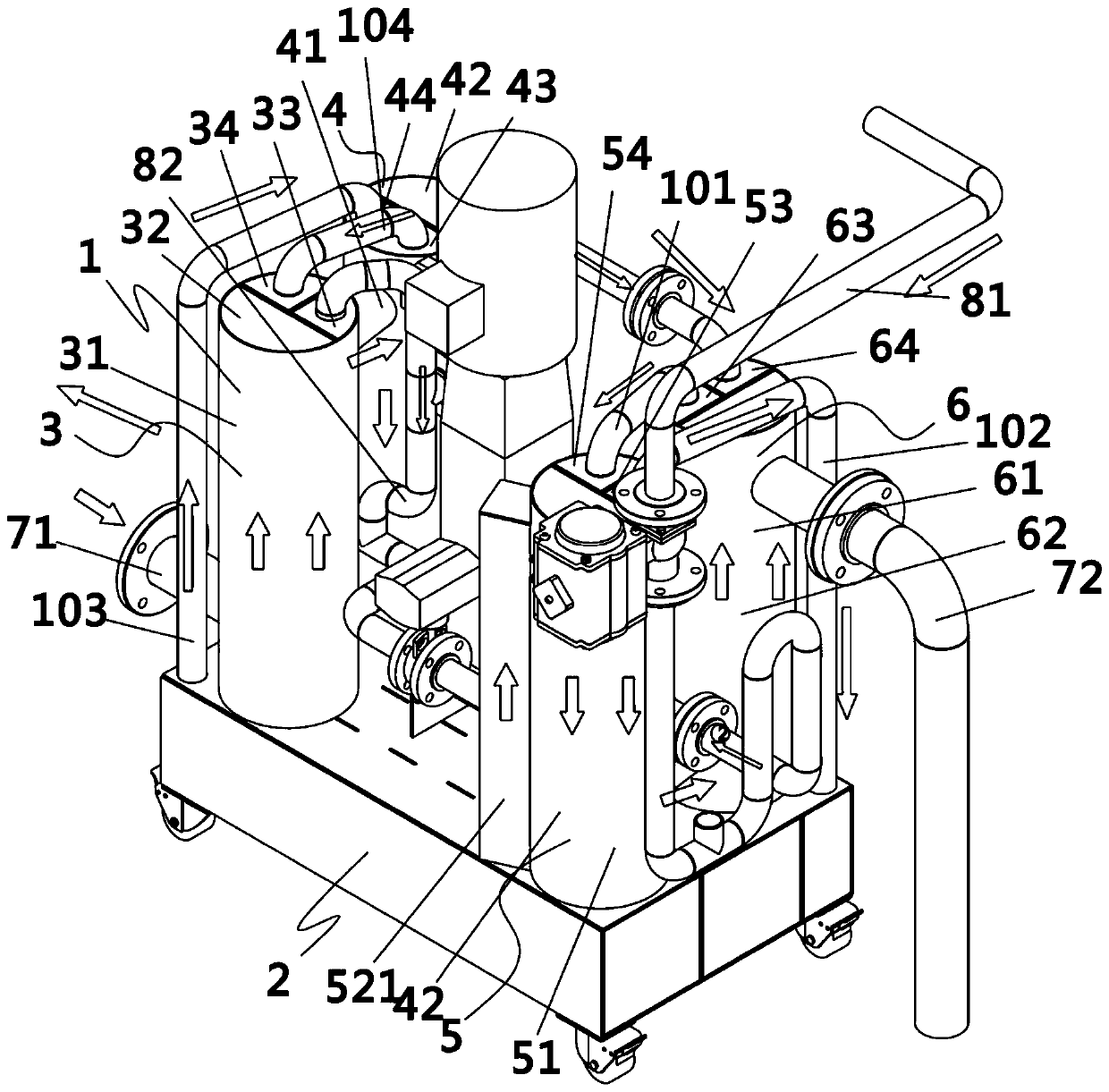

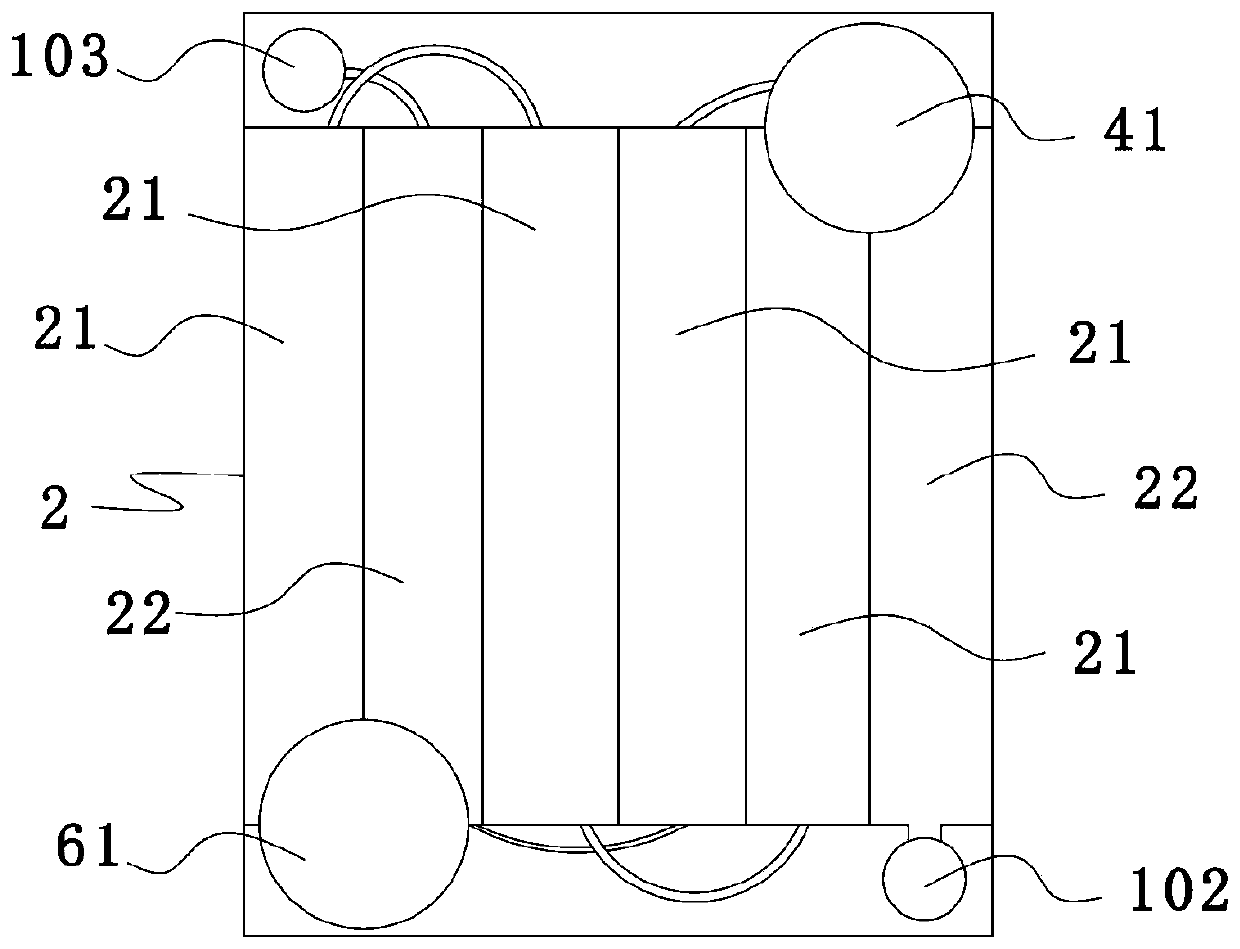

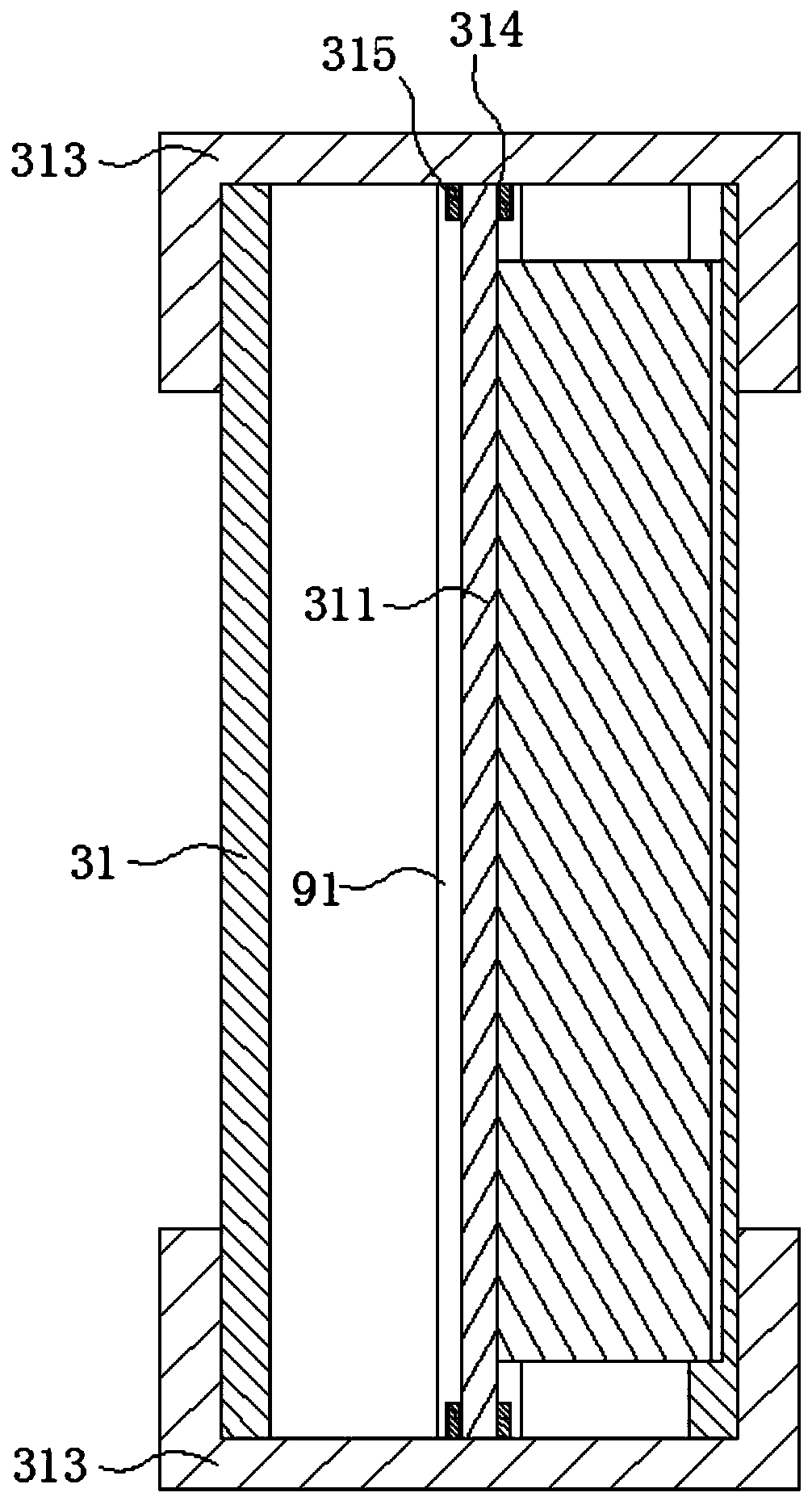

[0025] A method based on the environmental protection treatment of printing and dyeing wastewater includes the following steps: (1) After the printing and dyeing wastewater is heat-exchanged through a heat exchange device, it is passed into a regulating tank; the temperature of the printing and dyeing wastewater after heat exchange is 30°C; Add an acid-base regulator to the adjustment tank to adjust the pH to 8.5, and the COD to 300mg / L; specifically, the acid-base regulator includes the following components by weight: 25 parts of citric acid, 2 parts of sodium hydroxide, and 1 of hydrochloric acid solution; (2) The waste water is introduced into the reaction tank, and alkaline resin is added to the reaction tank. The reaction tank is a concrete tank, and the waste water is discharged after stirring and reacting for 1 hour; specifically, the alkaline resin is a strong alkaline anion exchange resin. The COD of the wastewater discharged after the reaction treatment is less than 50...

Embodiment 2

[0040] A method based on the environmental protection treatment of printing and dyeing wastewater, including the following steps: (1) After the printing and dyeing wastewater is heat-exchanged through a heat exchange device, it is passed into a regulating tank; the temperature of the printing and dyeing wastewater after heat exchange is 35°C; Add an acid-base regulator to the adjustment tank to adjust the pH to 9.5, and the COD to 500mg / L; specifically, the acid-base regulator includes the following components in parts by weight: 33 parts of citric acid, 4 parts of sodium hydroxide, and 3 parts of hydrochloric acid solution; (2) The waste water is introduced into the reaction tank, and alkaline resin is added to the reaction tank. The reaction tank is a concrete tank, and the waste water is discharged after stirring and reacting for 2 hours; specifically, the alkaline resin is a strong alkaline anion exchange resin, which is passed through The COD of the wastewater discharged af...

Embodiment 3

[0042] A method based on the environmental protection treatment of printing and dyeing wastewater includes the following steps: (1) After the printing and dyeing wastewater is heat-exchanged through a heat exchange device, it is passed into a regulating tank; the temperature of the printing and dyeing wastewater after heat exchange is 30°C; Add an acid-base regulator to the adjustment tank to adjust the pH to 8.5 and COD to 300mg / L; specifically, the acid-base regulator includes the following components by weight: 25 parts of citric acid, 4 parts of sodium hydroxide, and 1 of hydrochloric acid solution; (2) The waste water is passed into the reaction tank, and alkaline resin is added to the reaction tank. The reaction tank is a concrete tank, and the waste water is discharged after stirring and reacting for 1.5 hours; specifically, the alkaline resin is a strong alkaline anion exchange resin, The COD of the wastewater discharged after the reaction treatment is less than 50 mg / L;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com