Automatic and efficient surrounding edge disassembling device for multi-layer foamed ceramic tunnel kiln

A technology of foam ceramics and tunnel kiln, which is applied in the direction of furnace type, furnace, charge composition/state, etc. It can solve the problems of low disassembly efficiency, high labor intensity, and increased production cost of foam ceramics, so as to reduce production costs and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings. It is only stated here that the words for directions such as up, down, left, right, front, back, inside, and outside that appear or will appear in the text of the present invention are only based on the accompanying drawings of the present invention, and are not specific to the present invention. limited.

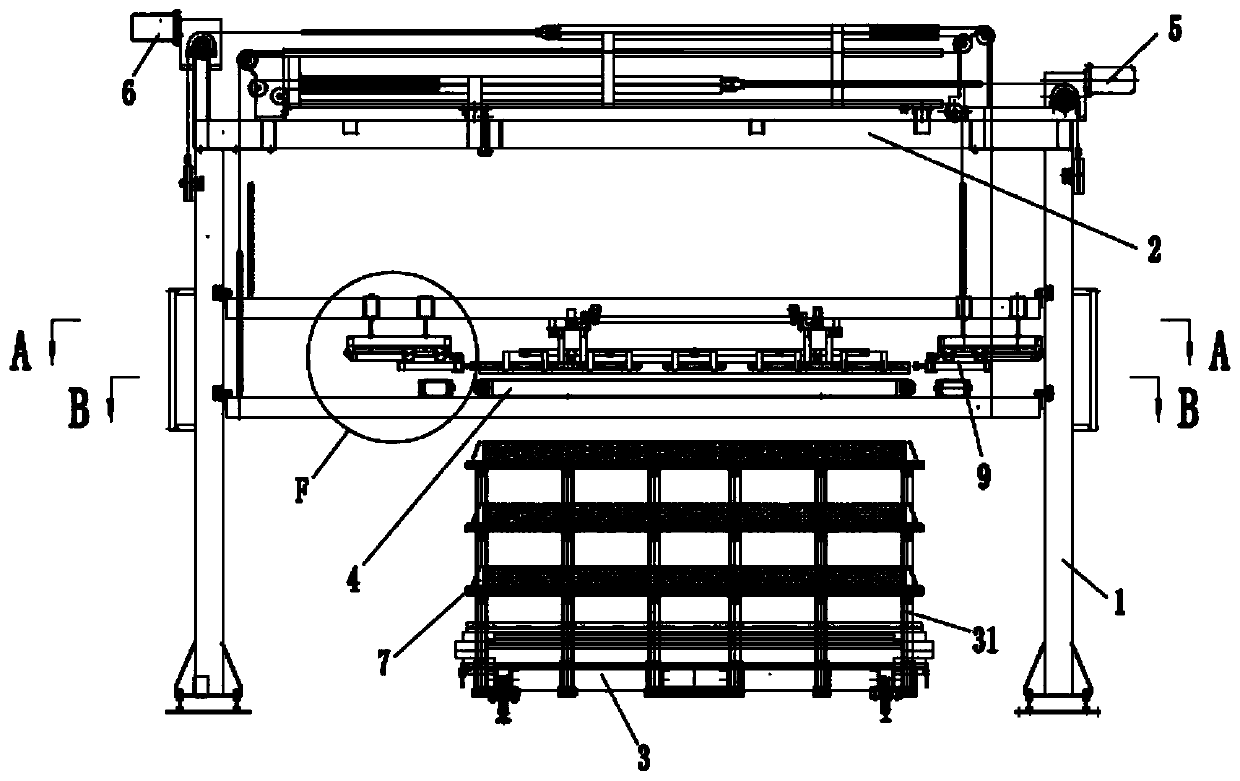

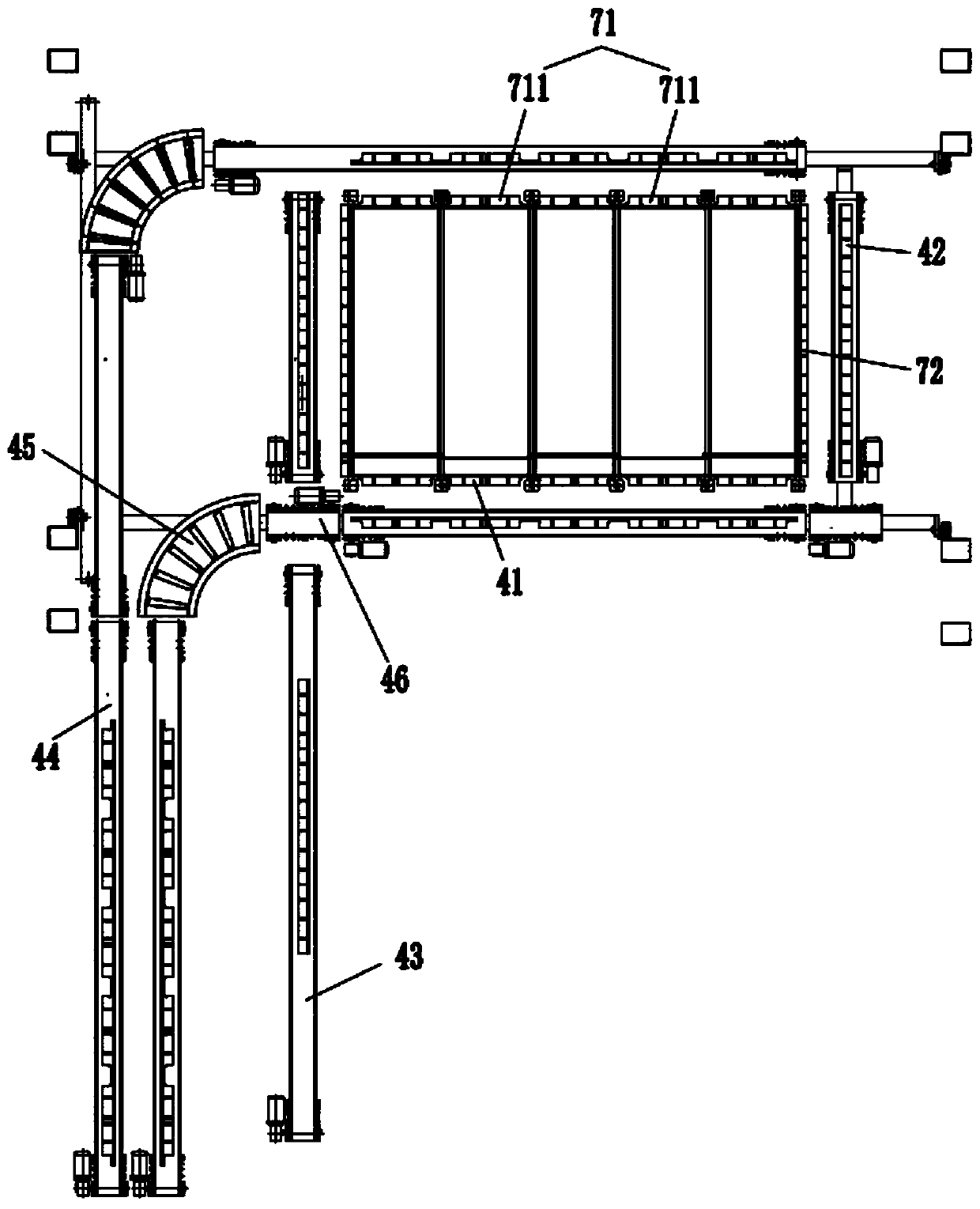

[0046] like Figure 1-3 As shown, the multi-layer foam ceramic tunnel kiln automatic and efficient unloading device of the present invention includes a frame 1, a crossbeam 2, a kiln car 3 for conveying ceramic raw materials, a suction mechanism for dismounting the rim, and a The dismantled edge is transported to the conveying mechanism 4 of the next station, the upper lifting mechanism 5 that drives the suction mechanism up and down, and the lower lifting mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com