High-efficiency and low-loss multistage acceleration mechanism

A speed-increasing mechanism and low-loss technology, applied in mechanical equipment, transmission parts, friction transmission, etc., can solve the problems of low practical value, poor transmission efficiency, complex energy loss structure, etc., achieve good fixing effect and reduce wear and tear , the effect of increasing the effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

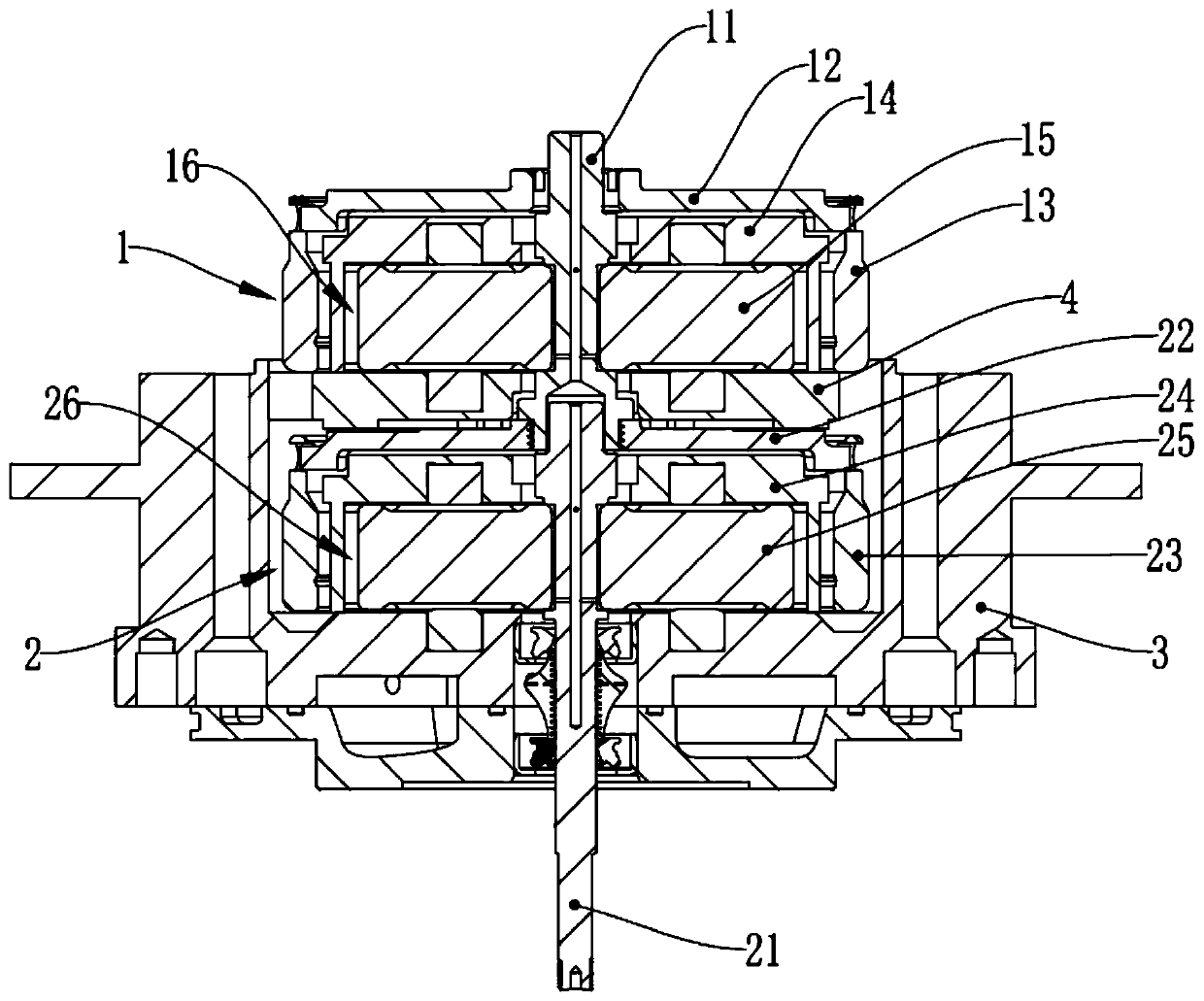

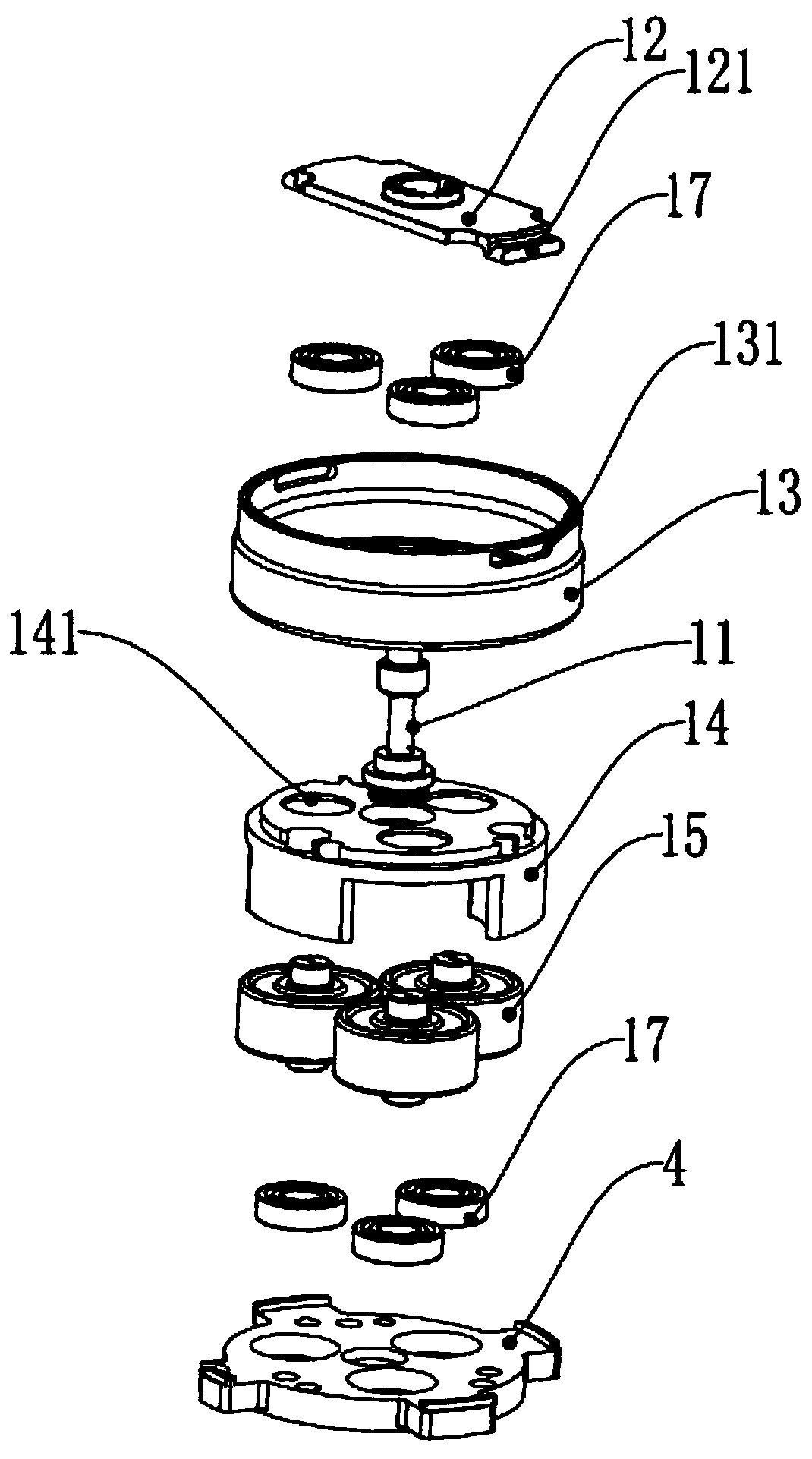

[0042] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

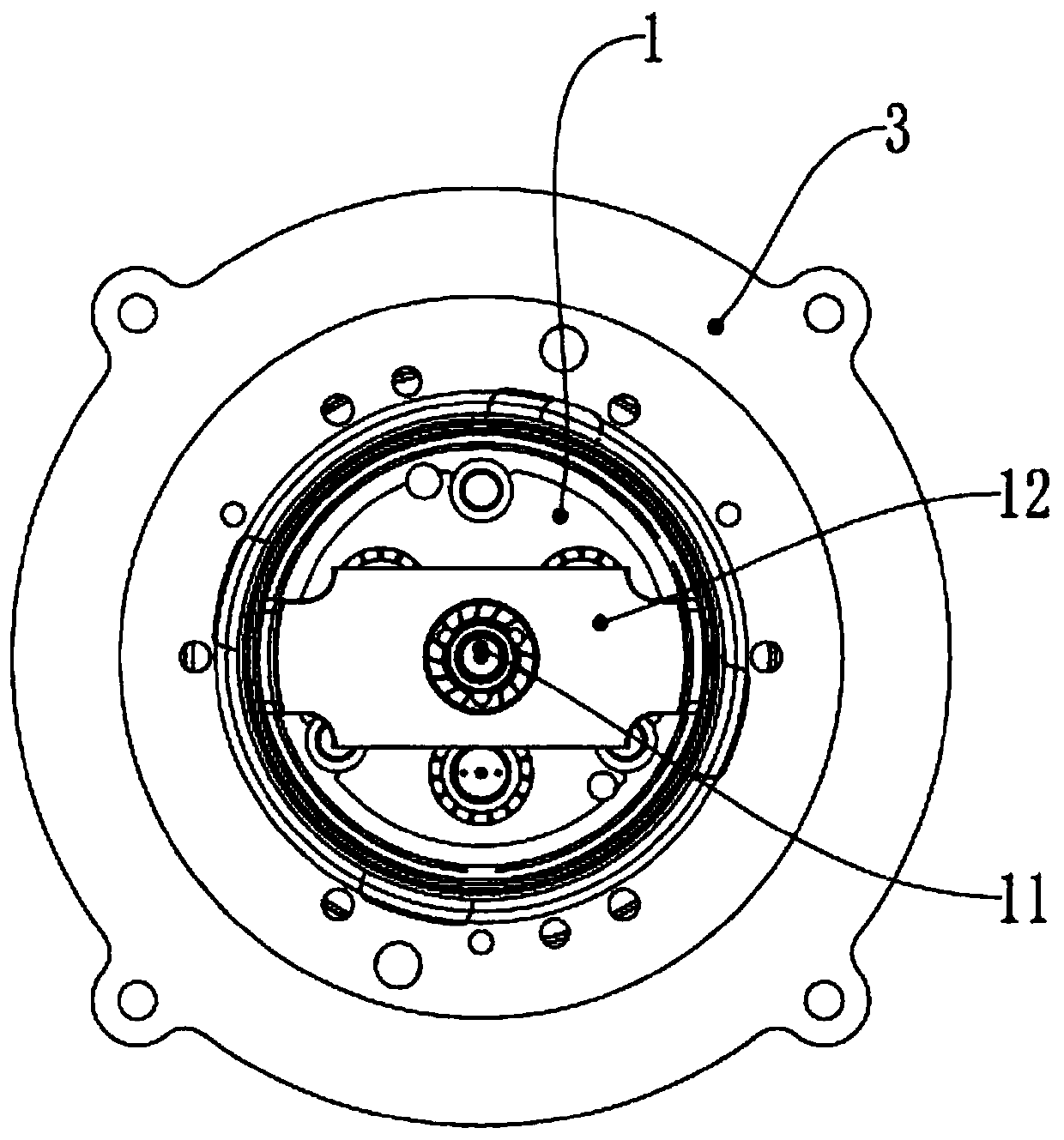

[0043] A high-efficiency and low-loss multi-stage speed-up mechanism in this embodiment includes a first-stage planetary gear component 1, a secondary planetary gear component 2, a top cover 3 and a fixed plate 4;

[0044] The first-stage planetary wheel part 1 and the second-stage planetary wheel part 2 are set up and down, and the top cover 3 is set on the outside of the second-stage planetary wheel part 2. The first-stage planetary wheel part 1 is provided with a first transmission shaft 11, and the second-stage planetary wheel The component 2 is provided with a second transmission shaft 21, and the first transmission shaft 11 is in transmission cooperation with the second transmission shaft 21;

[0045] The fixed plate 4 is arranged between the primary planetary wheel component 1 and the seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com