Anti-blocking feeding mechanism for textile elasticizer

A feeding mechanism and anti-blocking technology, applied in the field of textile production, can solve problems such as blocking the texturing machine and affecting the use, and achieve the effects of safe and convenient use, convenient assembly and installation, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

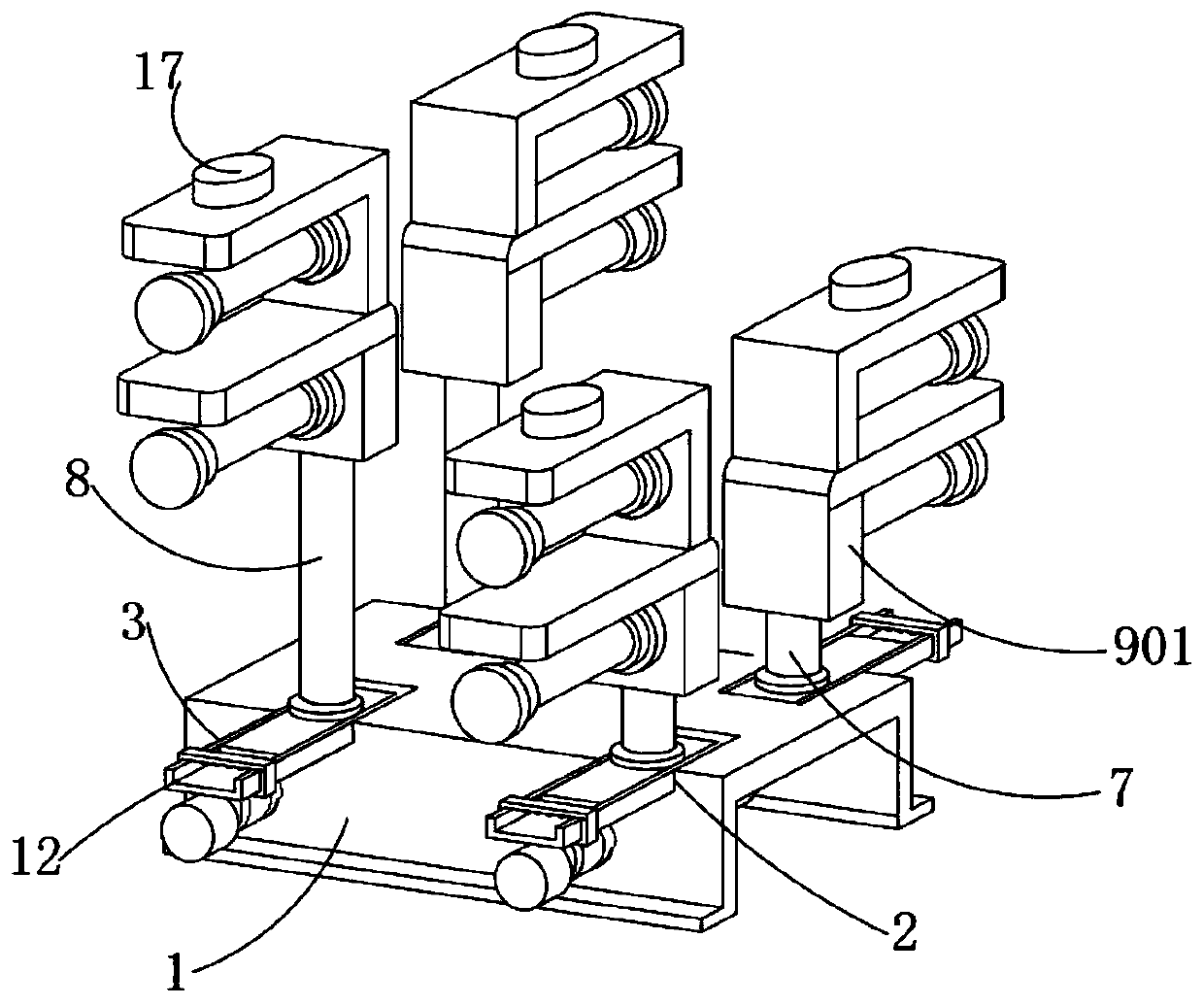

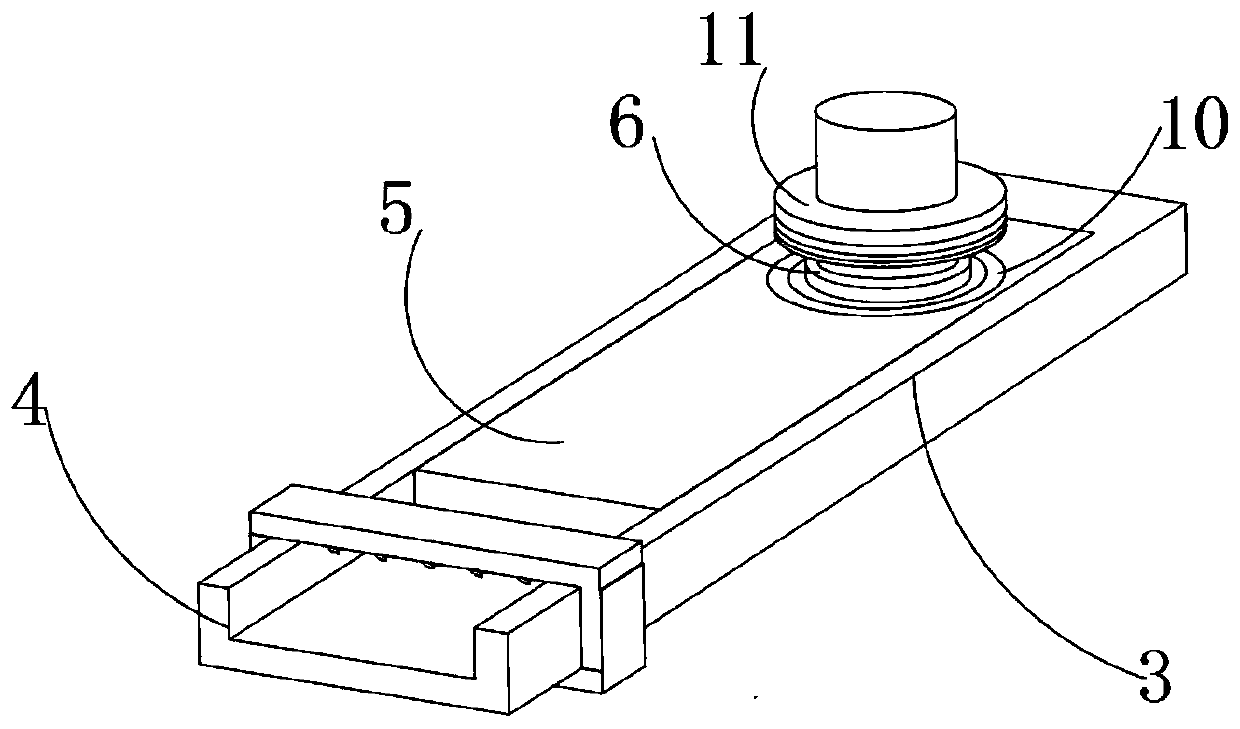

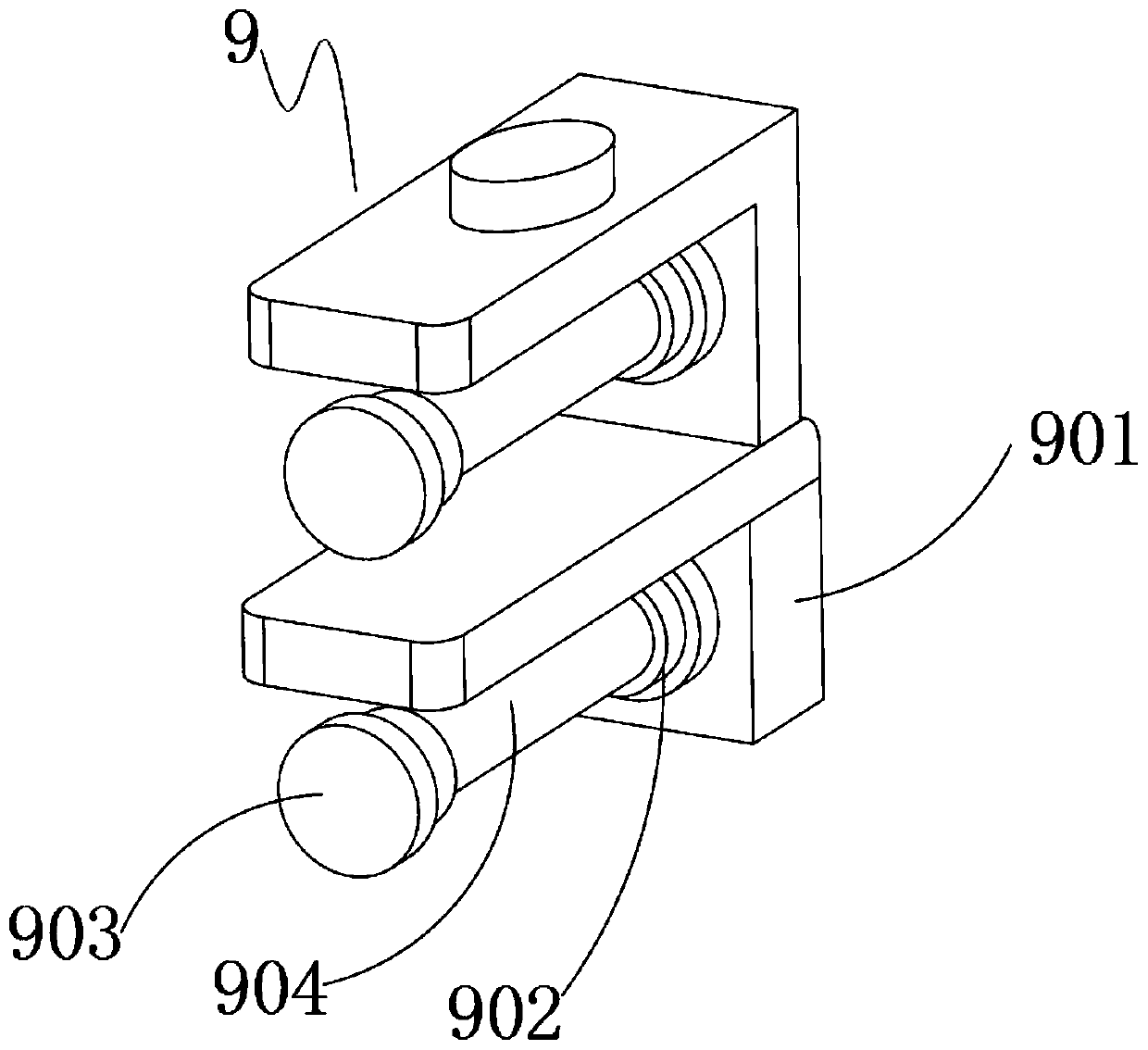

[0025] Example: such as Figure 1-5 As shown, the present invention provides a technical solution, an anti-clogging feeding mechanism for a textile texturing machine, including a support frame 1, grooves 2 are opened at the top four corners of the support frame 1, and the inner walls of the groove 2 are welded with fixed Plate 3, the top of the fixed plate 3 is provided with a chute 4, the inside of the chute 4 is slidably connected with a slider 5, the top edge of the slider 5 is embedded with a bearing 6, and the first support rod 7 is sleeved inside the two bearings 6 , the other two bearings 6 are sleeved with a second support rod 8, and the top ends of the first support rod 7 and the second support rod 8 are equipped with a dredging assembly 9, and the dredging assembly 9 includes an L-shaped connecting plate 901, a rotating shaft 902, Limiting block 903 and guide groove 904;

[0026] The top of the first support rod 7 and the second support rod 8 are both sleeved with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com