A plastic light-changing agricultural film with long-lasting light-changing effect and preparation method thereof

A light-converting agricultural film and long-lasting technology, applied in the field of plastic light-converting agricultural film and its preparation, can solve the problems of affecting the appearance and smoothness of the product, reducing the light-conversion efficiency of the film, and poor uniformity of the film, so as to achieve a lasting light-conversion effect and a good appearance finish. , excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

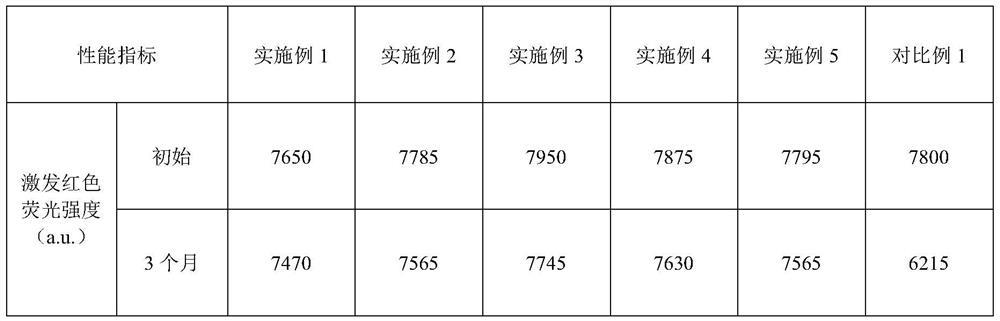

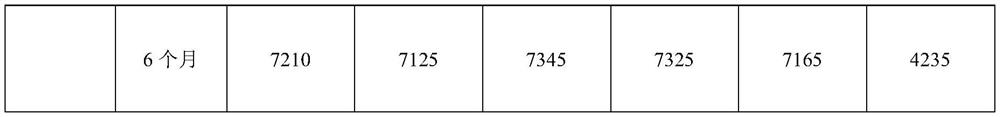

Examples

Embodiment 1

[0028] (1) Mix liquid glass and deionized water, stir well to form a uniform system, then add inorganic rare earth light conversion agent and ceramic microspheres into the system and soak for 1.5h, stir evenly to prepare a slurry, and then move the slurry into a pressure spray In the spray granulation of the dryer, the particles were collected and washed with absolute ethanol for 3 times, then heated and dried at 110°C for 1.5h, and the inorganic rare earth light conversion agent was fixed on the surface of the ceramic microspheres through the solidification process of liquid glass to obtain Composite inorganic rare earth light conversion agent; the inorganic rare earth light conversion agent is yttrium-europium oxysulfide; the ceramic microspheres are alumina ceramic microspheres; during the spray granulation process, the heat source temperature of the pressure spray dryer is 185°C, and the outlet temperature is 150℃, the pump pressure is 1.5MPa;

[0029] The raw material com...

Embodiment 2

[0033] (1) Mix liquid glass and deionized water, stir well to form a uniform system, then add inorganic rare earth light conversion agent and ceramic microspheres into the system and soak for 1 hour, stir evenly to prepare slurry, and then move the slurry into pressure spray drying In the spray granulation of the machine, the particles are collected and washed twice with absolute ethanol, and then heated and dried at 105°C for 2 hours, and the inorganic rare earth light conversion agent is fixed on the surface of the ceramic microsphere through the solidification process of the liquid glass to obtain a composite inorganic Rare earth light conversion agent; the inorganic rare earth light conversion agent is yttrium-europium oxysulfide; the ceramic microspheres are silica ceramic microspheres; during the spray granulation process, the heat source temperature of the pressure spray dryer is 185°C, and the outlet temperature is 130°C ℃, the pump pressure is 1.2MPa;

[0034] The raw...

Embodiment 3

[0038] (1) Mix liquid glass and deionized water, stir well to form a uniform system, then add inorganic rare earth light conversion agent and ceramic microspheres into the system and soak for 2 hours, stir evenly to prepare slurry, and then move the slurry into pressure spray drying In the spray granulation of the machine, the particles were collected and washed with absolute ethanol four times, and then heated and dried at 115°C for 1 hour, and the inorganic rare earth light conversion agent was fixed on the surface of the ceramic microsphere through the solidification process of the liquid glass to obtain a composite inorganic Rare earth light conversion agent; inorganic rare earth light conversion agent is yttrium-europium oxysulfide; ceramic microspheres are silicon carbide ceramic microspheres; during the spray granulation process, the heat source temperature of the pressure spray dryer is 195°C, and the outlet temperature is 150°C , the pump pressure is 1.8MPa;

[0039] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com