Electric heating simulation heat source for general purpose isotope heat source

An electric heating and isotope technology, which is applied in the direction of ohmic resistance heating, ohmic resistance heating parts, and thermometers using electric/magnetic elements that are directly sensitive to heat, can solve the problems of poor equivalence and achieve the effect of ensuring effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described below based on examples, but the present invention is not limited to these examples. In the following detailed description of the present invention, some specific details are described in detail. Those skilled in the art can fully understand the present invention without the description of these details. In order to avoid obscuring the essence of the present invention, well-known methods, processes, procedures, and components are not described in detail.

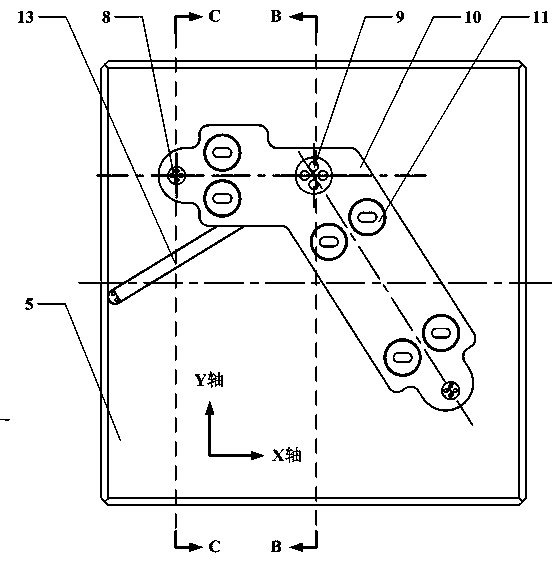

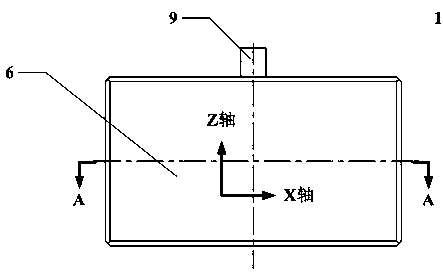

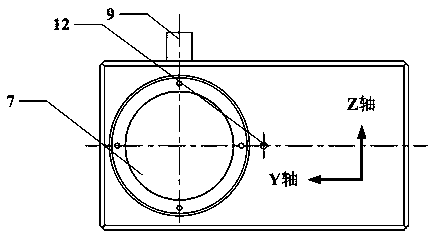

[0028] Refer below Figure 1a to Figure 3b The embodiment of the electric heating simulation heat source of the present invention is described.

[0029] A general-purpose isotope heat source electric heating simulation heat source, which is characterized in that it includes a heating element 1, an electrical insulation layer 2, a sealing layer 3, an impact buffer layer 4, a thermal insulation layer 5, an atmospheric ablation layer 6, and a loading channel 7 , Junction terminal 9, tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com