Method for determining total output of hydrogen sulfide in oil well

A determination method and technology of hydrogen sulfide, applied in the direction of material analysis, measuring device, color/spectral characteristic measurement through observation of the influence on chemical indicators, etc., can solve the problems of low wellhead compliance rate, potential safety hazards, and high treatment costs , to achieve the effect of reducing potential safety hazards, increasing the compliance rate, and reducing the amount of dosing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A typical oil well A in a block of Shengli Oilfield, with a daily fluid production of 30m 3 , water content 86%, associated gas volume 66Nm 3 / d, the wellhead temperature is 55°C, and the pressure is 0.55MPa.

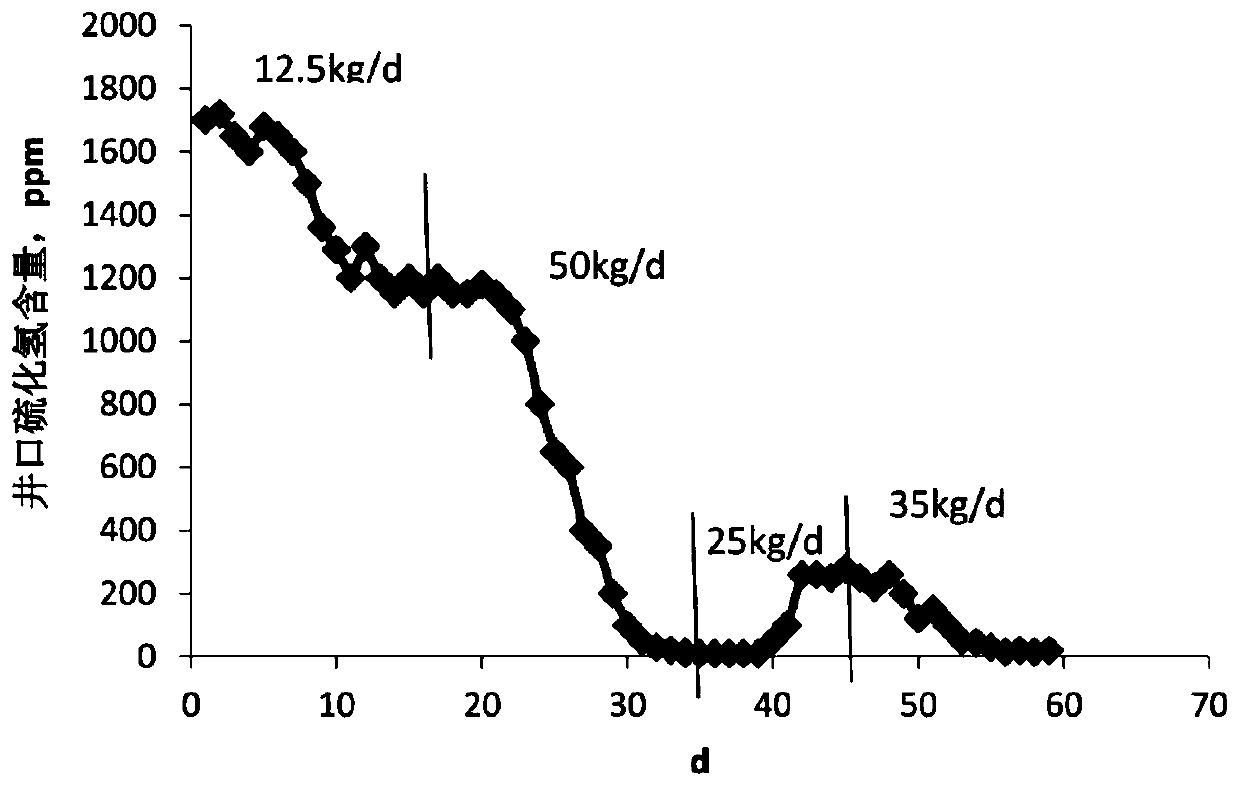

[0050] The traditional method is used to estimate the hydrogen sulfide production of the well, which is the product of gas volume and gas phase hydrogen sulfide content = 1700*60*1.5 / 1000000=0.15kg / d, if the sulfur capacity of the desulfurizer is 1.2%, then the desulfurizer of the well The theoretical dosage is 0.15 / 1.2%=12.5kg / d. Initially, the desulfurizer is added at 12.5kg / d. After 10 days of adding, the hydrogen sulfide content drops to 1200ppm and no longer drops. In order to achieve the standard, increase the dosage to 50kg / d, after 10 days, the hydrogen sulfide content dropped below 20ppm. In order to save the dosage, the dosage was reduced to 25kg / d. After 5 days, the hydrogen sulfide content rose to 300ppm, indicating that the dosage was insufficient, ...

Embodiment 2

[0091] Oil well B in a block of Shengli Oilfield, with a daily fluid production of 30m 3, moisture content 90%, associated gas volume 90Nm 3 / d, the wellhead temperature is 65°C, and the pressure is 0.7MPa.

[0092] The traditional method is used to estimate the hydrogen sulfide production of the well, which is the product of gas volume and gas phase hydrogen sulfide content = 2500*90*1.5 / 1000000=0.34kg / d, if the sulfur capacity of the desulfurizer is 1.2%, then the well desulfurizer The theoretical dosage is 0.34 / 1.2%=28.3kg / d. After adding the desulfurizer at the initial rate of 28.3kg / d for 12 days, the hydrogen sulfide content drops to 900ppm and no longer drops. In order to achieve the standard, increase the dosage to 60kg / d After 13 days, the hydrogen sulfide content dropped to about 400ppm and did not continue to drop. Increase the dosage again to 80kg / d. After 9 days, the hydrogen sulfide content reached 20ppm, which met the safety requirements. This process took abou...

Embodiment 3

[0132] Well C in a certain block of Shengli Oilfield, with a daily fluid production of 60m 3 , water content 94%, associated gas volume 110Nm 3 / d, the wellhead temperature is 85°C, and the pressure is 1.0MPa.

[0133] The hydrogen sulfide production of this well is estimated by the traditional method, which is the product of gas volume and gas phase hydrogen sulfide content = 20000*110*1.5 / 1000000=3.3kg / d, if the sulfur capacity of the desulfurizer is 1.2%, then the well desulfurizer The theoretical dosage is 3.3 / 1.2%=275kg / d, according to the dosage of the desulfurizer, the hydrogen sulfide can only be treated to 17000ppm, and then after 3 rounds of adjustment, the dosage will be increased to 1800kg It takes 55 days for the hydrogen sulfide to be stably controlled below 20ppm, of which 40 days are not up to standard.

[0134] Utilize the method of the present invention to determine the total output of oil well hydrogen sulfide, concrete steps are as follows:

[0135] (1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com