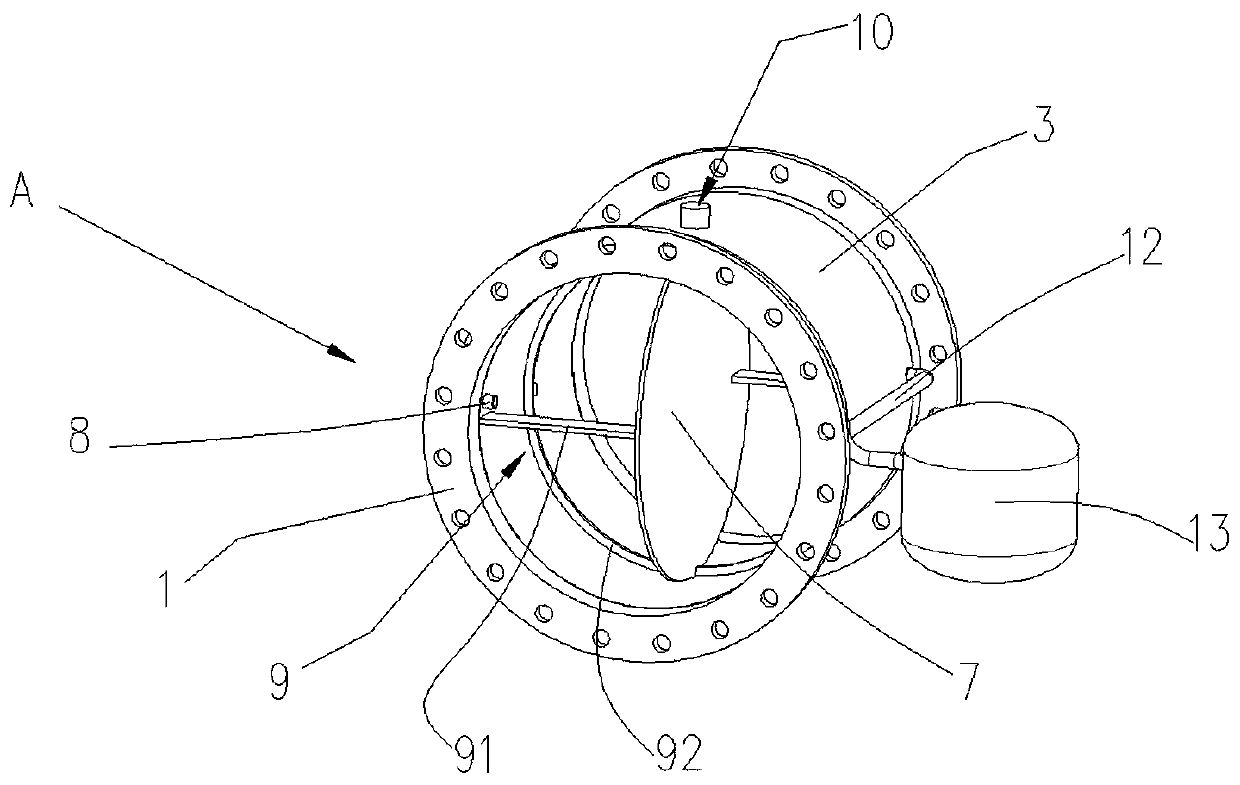

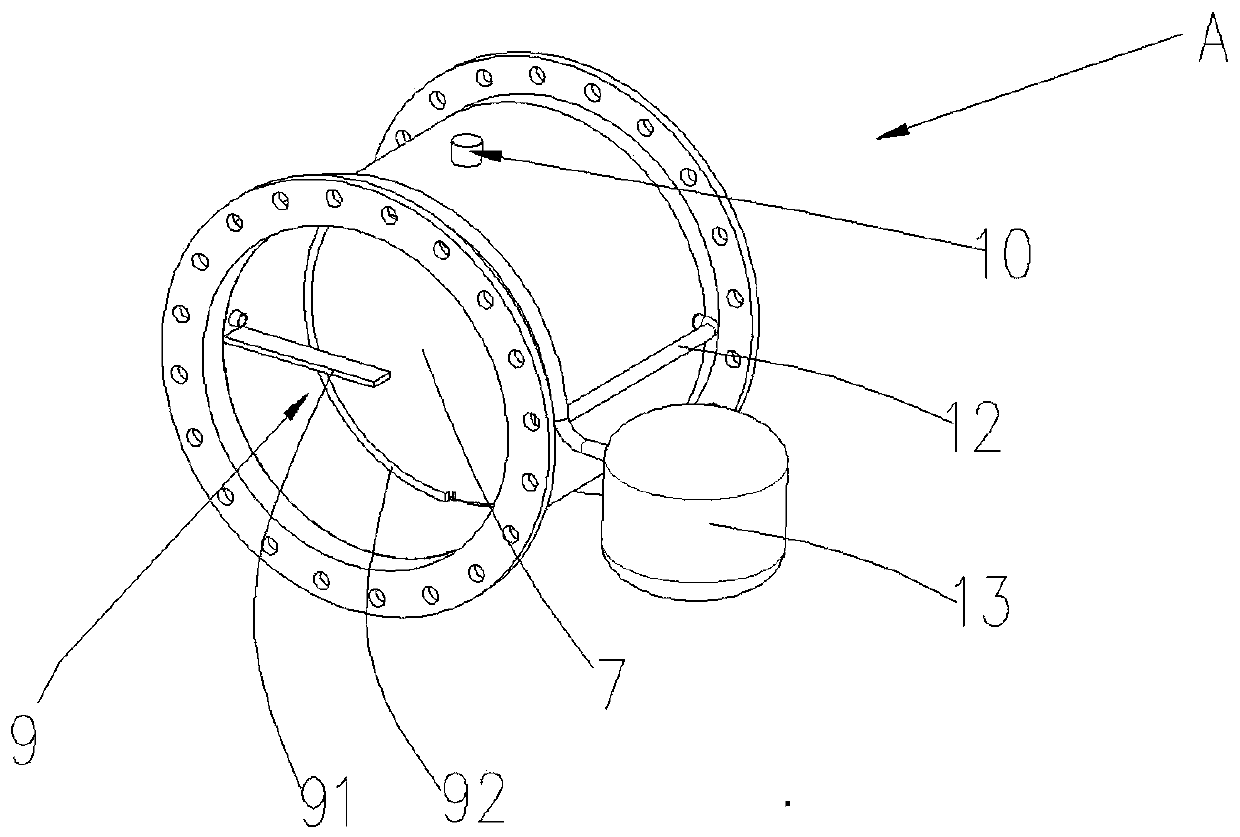

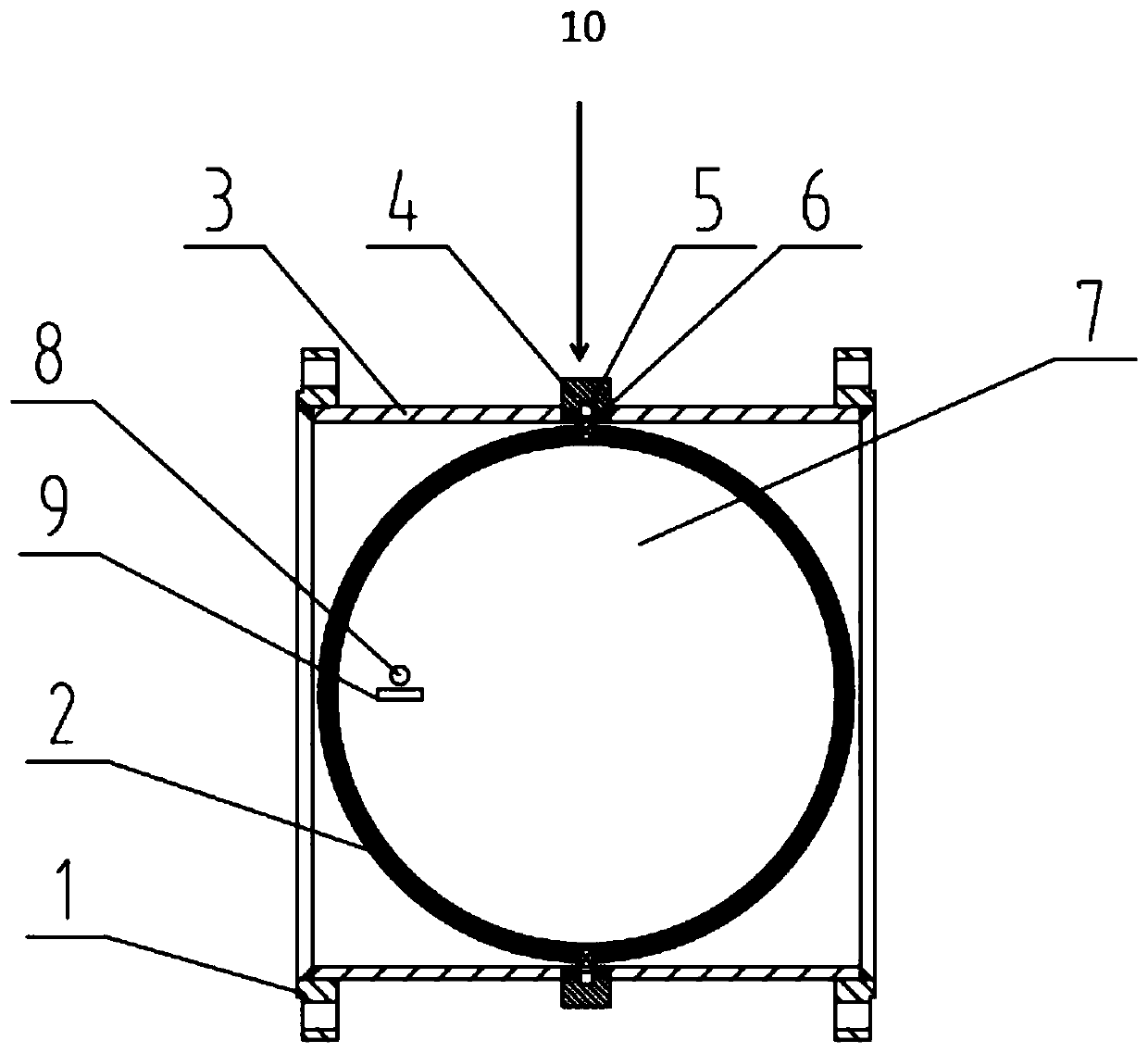

Two-way flame-proof valve and flame-proof system used for dust environment

An explosion-proof and environmental technology, applied in safety valves, balance valves, valve devices, etc., can solve the problems of limited use range, difficulty in reliable verification of explosion-proof performance, etc., and achieve the effects of high cost performance, simple structure and stable state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be noted that the described embodiments are only some of the embodiments of the present application, rather than all of the embodiments. The following description of at least one exemplary embodiment is actually only illustrative, and should not be used as the basis for the present application and limitations of its application.

[0024] In the present invention, the terms "first" and "second" are only used for descriptive purposes, and cannot be understood as indicating or implying relative importance; belonging to "plurality" refers to two or more than two, unless otherwise Clearly defined. The terms "installation", "connection", "connection", "fixed" and other terms should be understood in a broad sense, for example, "connection" can be fixed connection, detachable connection, or integral connection; "connection" can be It can be a direct connection or an indirect connection through an intermediary. The orientation or positional relationship indicated by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com