Belt tensioning mechanism, clothes dryer and belt tensioning method of clothes dryer

The technology of a tensioning mechanism and a clothes dryer, which is applied in the field of clothes dryers, can solve the problems of a complex tensioning mechanism structure, a complex overall structure, and a large space occupation, and achieve the effect of simple structure, simple operation, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

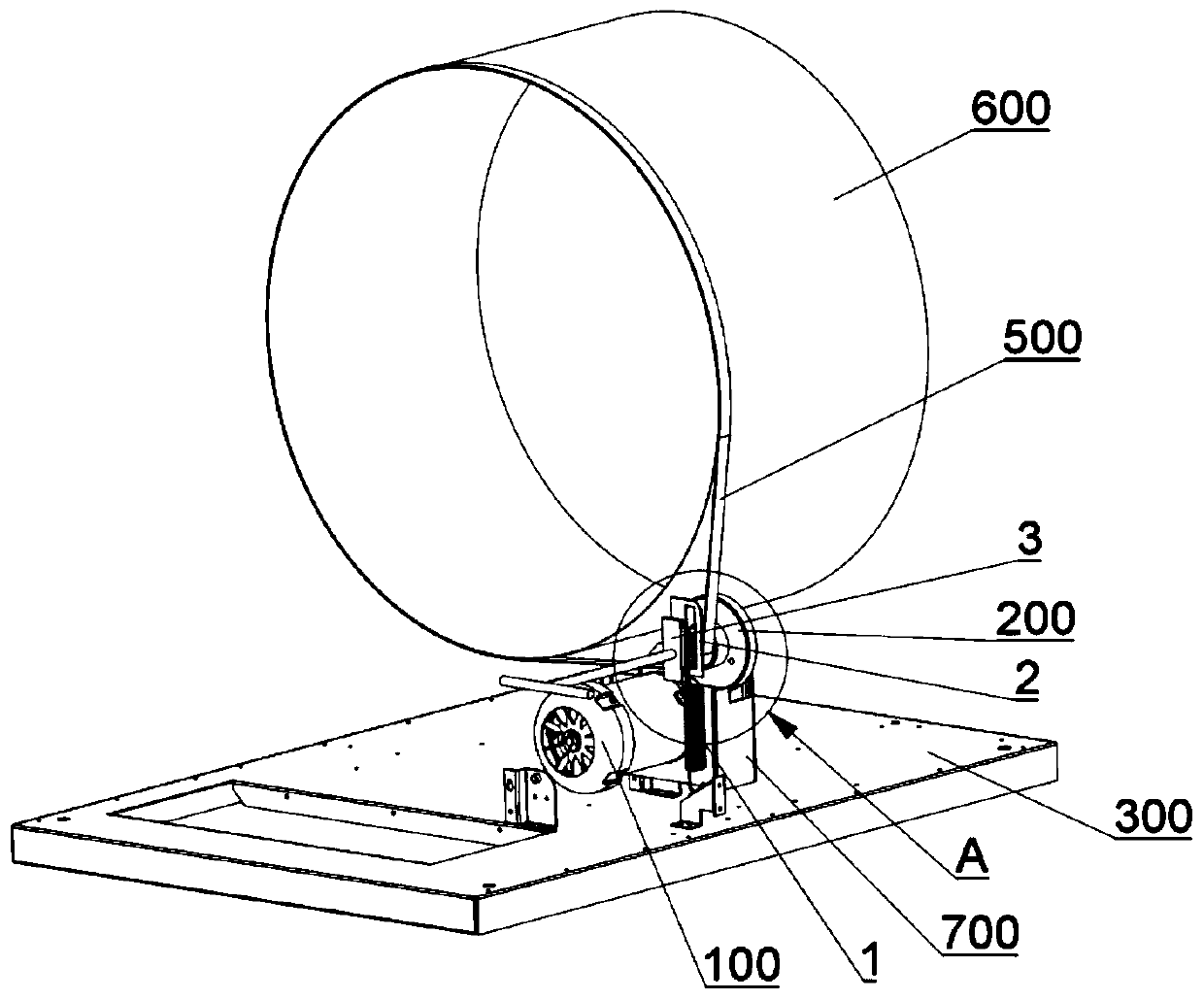

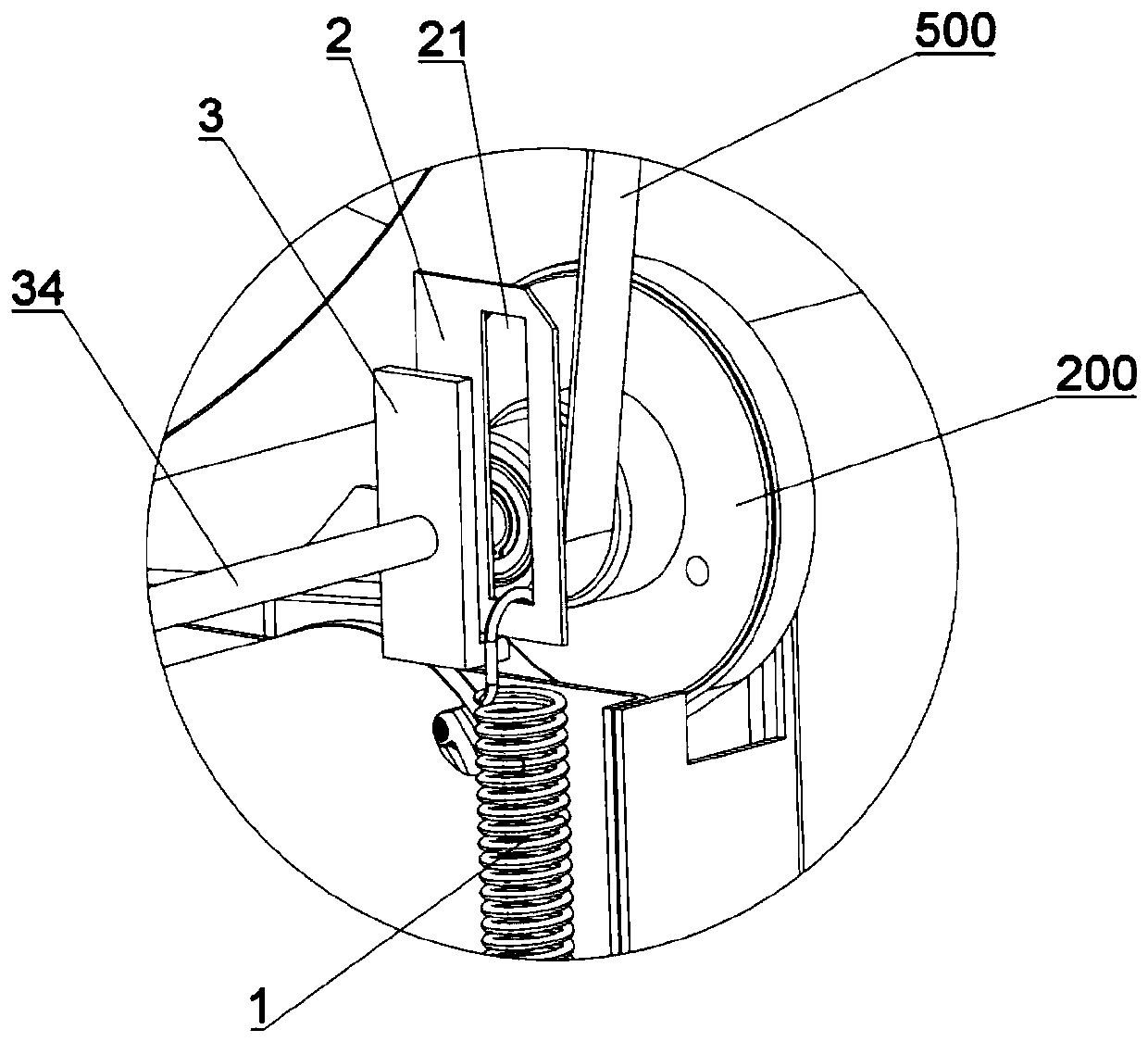

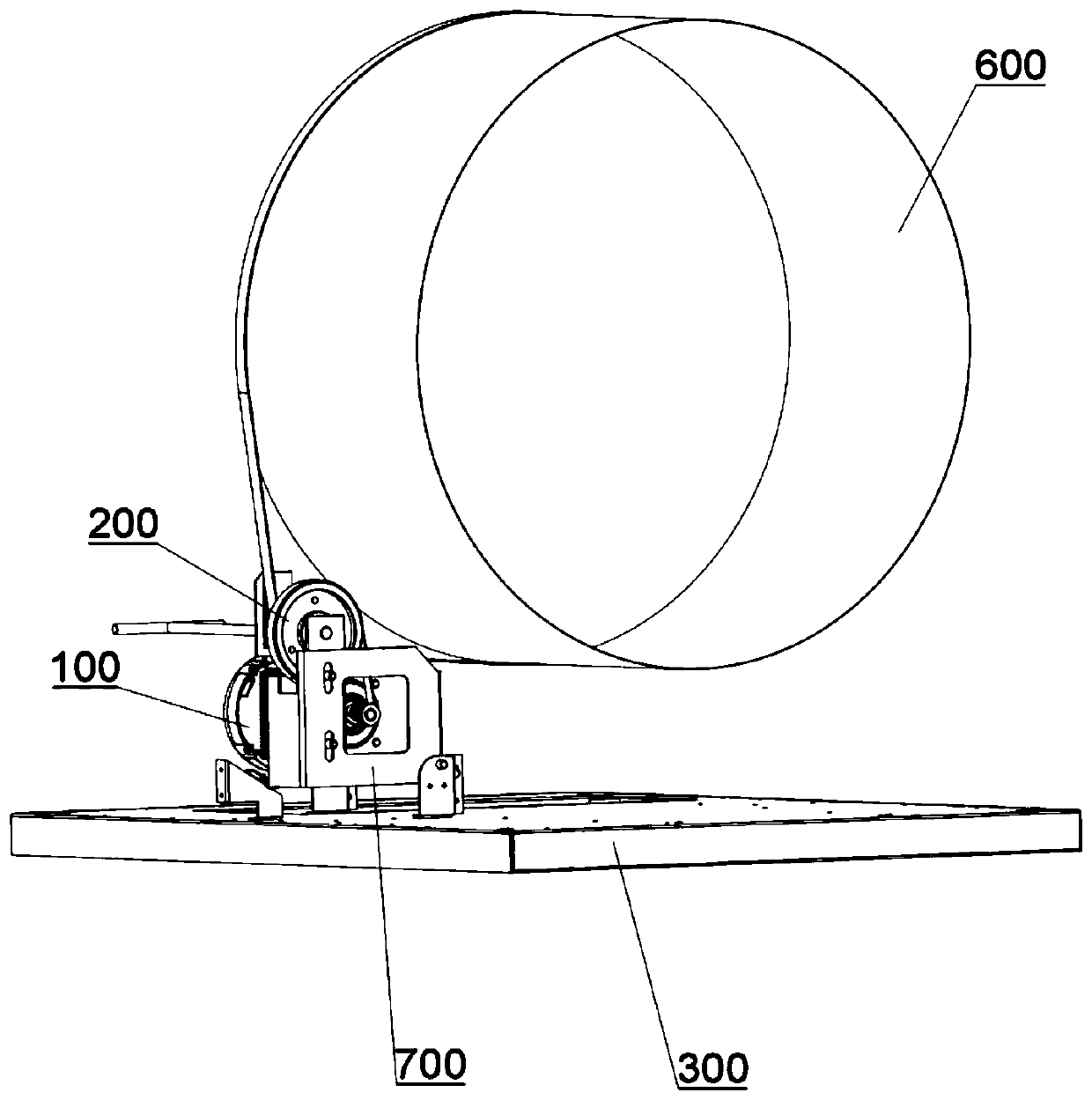

[0044] This embodiment provides a clothes dryer, such as Figure 1-Figure 4 As shown, it includes a motor 100, a motor reduction device 200, a base 300, a belt 500, a transmission belt, and a belt tensioning mechanism. Wherein, the output end of the motor 100 is connected to the motor reduction device 200 through a transmission belt, the motor reduction device 200 is connected to the outer cylinder 600 through a belt 500 , and the support frame 700 on the base 300 is used to support the motor reduction device 200 . The motor reduction device 200 is installed on the support frame 700, and the height of the motor reduction device 200 can be adjusted according to actual needs.

[0045]Specifically, adjustment holes may be provided on the support frame 700 along the height direction, and the height of the motor reduction device 200 may be adjusted by installing the motor reduction device 200 at different positions through the adjustment holes. Preferably, in this embodiment, a wa...

Embodiment 2

[0061] This embodiment provides a belt tensioning mechanism. The difference between this embodiment and the belt tensioning mechanism in Embodiment 1 lies in the connection structure between the mounting part 2 and the driving part 3. The second connection on the mounting part 2 in this embodiment The part 23 includes a first hole and a second hole connected together, the first hole is a semicircular hole, and the second hole is a rectangular hole, that is, the second connecting part 23 is a "horseshoe" shaped structure. The second hole limits the degree of freedom of movement in three directions, and the first hole limits the degree of freedom of movement in one direction. The two parts cooperate to achieve full positioning and prevent the first connecting part 31 from slipping in the second connecting part 23 .

[0062] Of course, the second connecting part 23 can also be of other structures, as long as the driving part 3 drives the installation part 2 to rotate through the c...

Embodiment 3

[0064] This embodiment provides a method for tensioning the belt of a clothes dryer, which is used for tensioning the belt 500 connected to the outer cylinder 600 of the clothes dryer in the first or second embodiment above, including the following steps:

[0065] S1. Install the mounting part 2 on the drive shaft of the belt 500 to be tensioned and connect one end of the elastic part 1 to the base 300 , and slide the other end into the slideway 21 of the mounting part 2 .

[0066] The installation part 2 is sleeved on the drive shaft of the belt 500 through the installation hole 22 to install the installation part 2 on the motor reduction gear 200 . Connect the first end of the elastic component 1 to the base 300, and hang the second end of the elastic component 1 in the elongated hole.

[0067] S2. Drive the installation part 2 to move through the drive part 3, so as to change the length of the elastic part 1 and drive the drive shaft to move so as to tension the belt 500. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com