Steel frame shaped building formwork system

A technology of building formwork and system, applied in the direction of construction, building structure, and on-site preparation of building components, can solve the problems of increasing the working strength of the formwork and the difficulty of dismantling, poor connection fastening, and low formwork utilization rate, etc., to achieve The effect of small quantity, good fastening and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A preferred embodiment of the present invention will be described below in conjunction with the accompanying drawings, and the technical solution in a preferred embodiment of the present invention will be clearly and completely described.

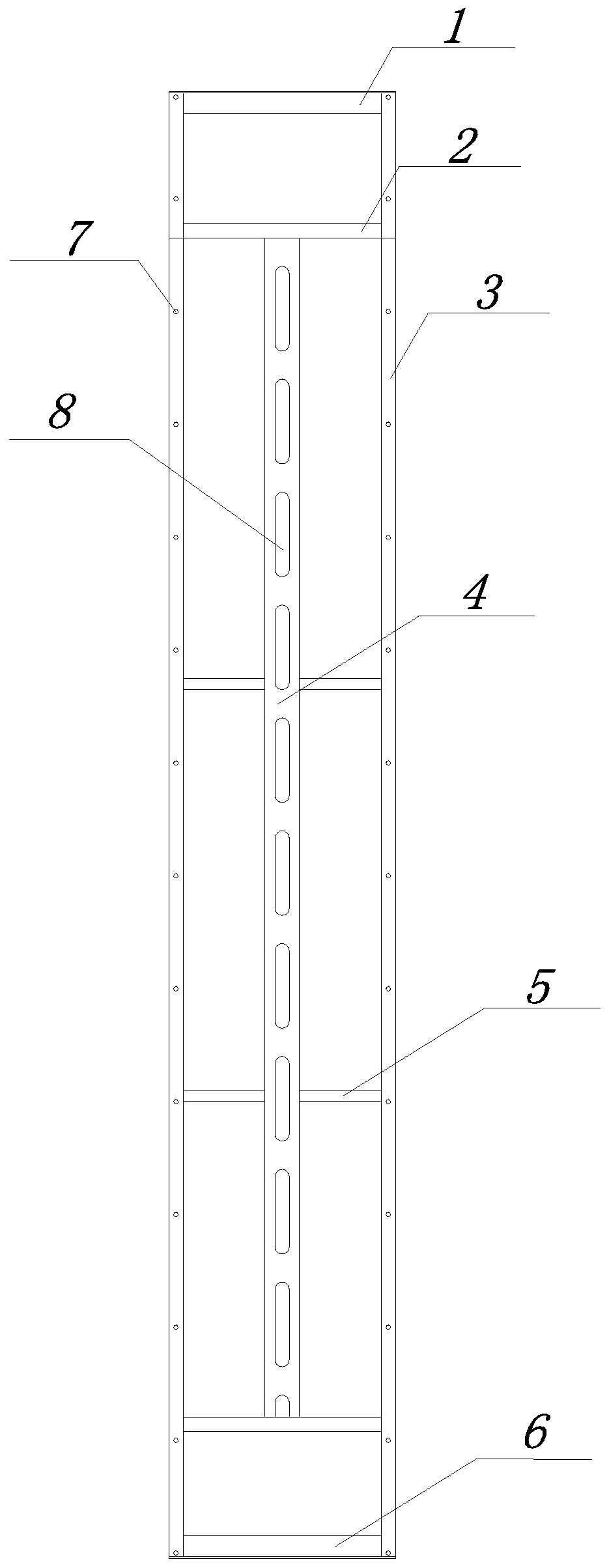

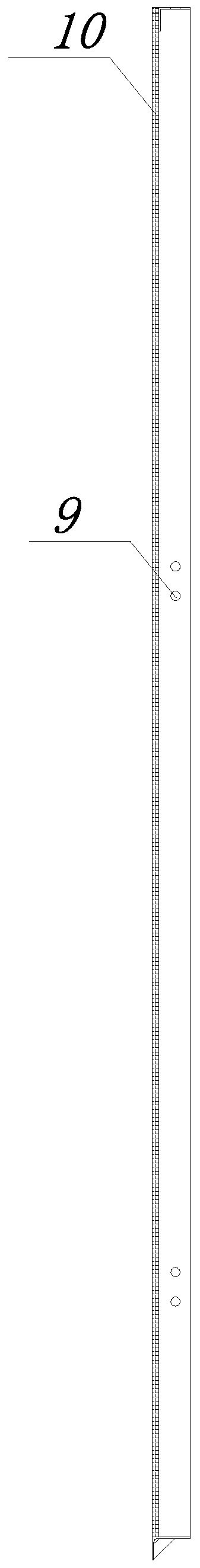

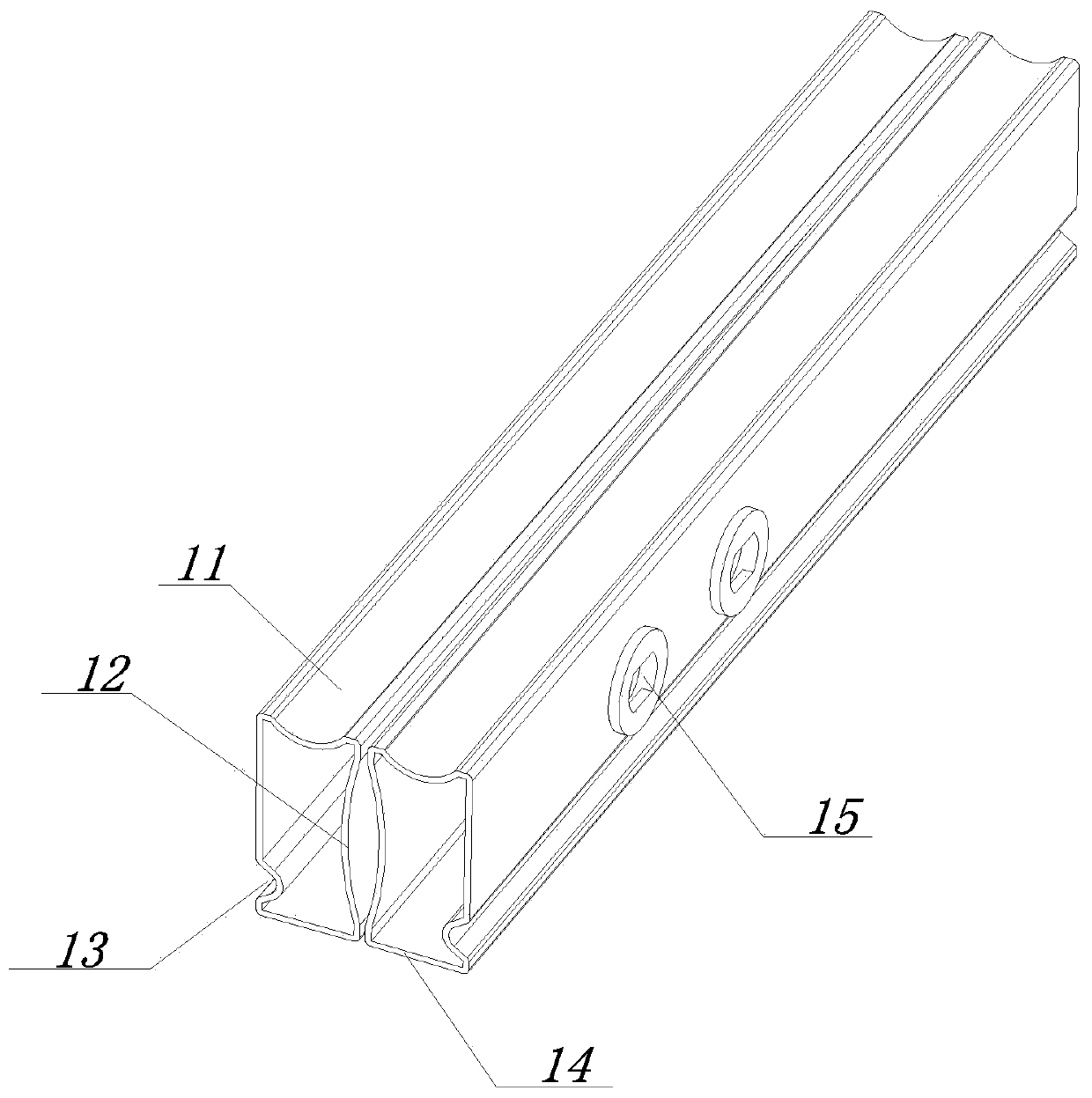

[0026] See Figure 1-Figure 6 , the present invention includes a number of frames, a number of frames, a number of templates 10 and a number of fixtures used in conjunction with each other.

[0027] The frame includes two main keels 3 arranged longitudinally, the upper ends of the two main keels 3 are fixedly connected by the upper frame 1, the lower ends of the two main keels 3 are fixedly connected by the lower frame 6, the two main keels 3, the upper The frame 1 and the lower frame 6 surround and form a closed rectangular frame structure; at least one secondary keel 4 is fixedly arranged between the two main keels 3, and the secondary keel 4 and the main keel 3 are parallel to each other; the front of the main keel 3 A number of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com