a load template

A formwork and support technology, which is applied to formwork/formwork components, connection parts of formwork/formwork/work frame, and on-site preparation of building components, can solve problems such as the inability of building formwork bearing strength to support temporary model structures. , to achieve the effect of simple structure, improving cycle efficiency and reducing utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

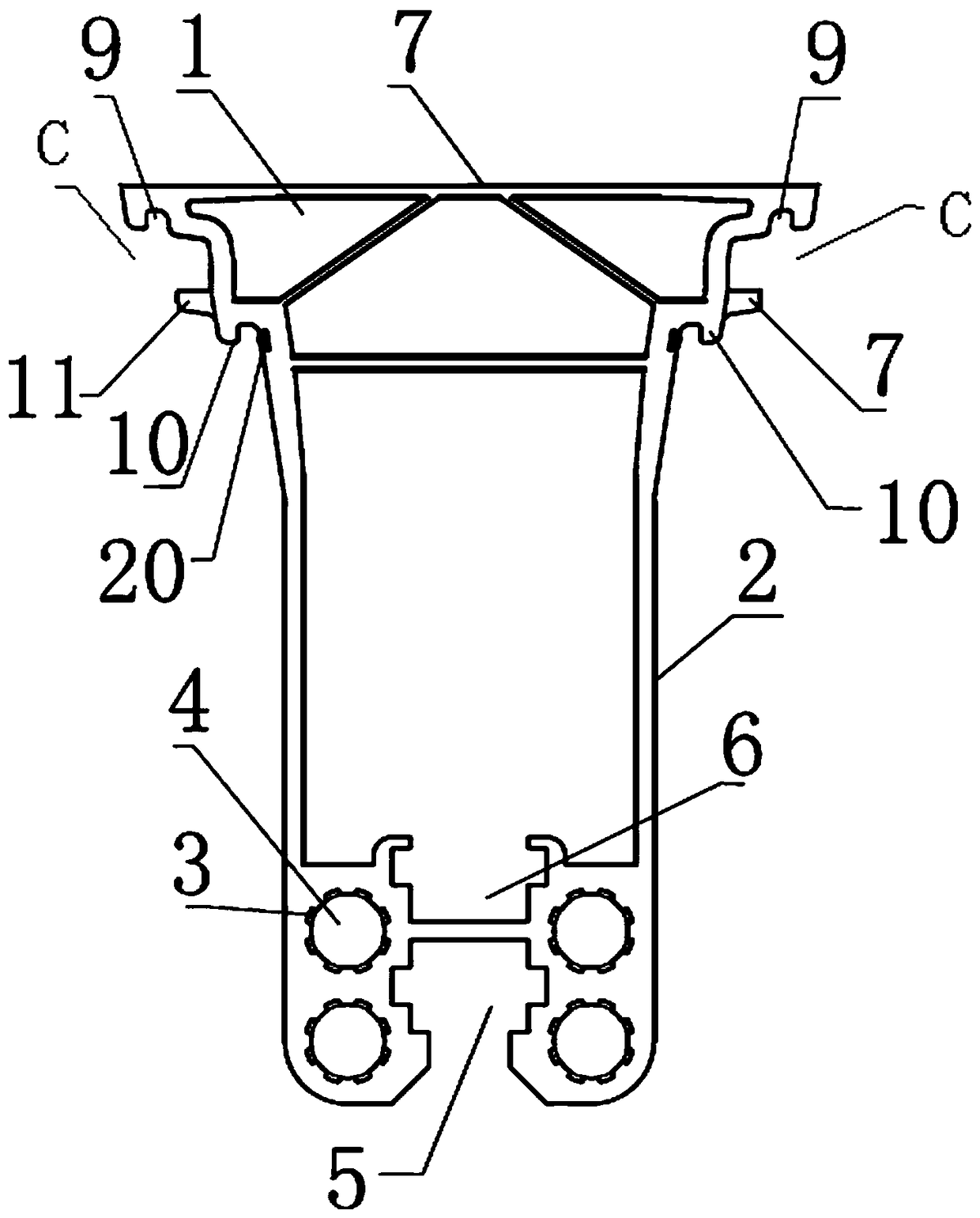

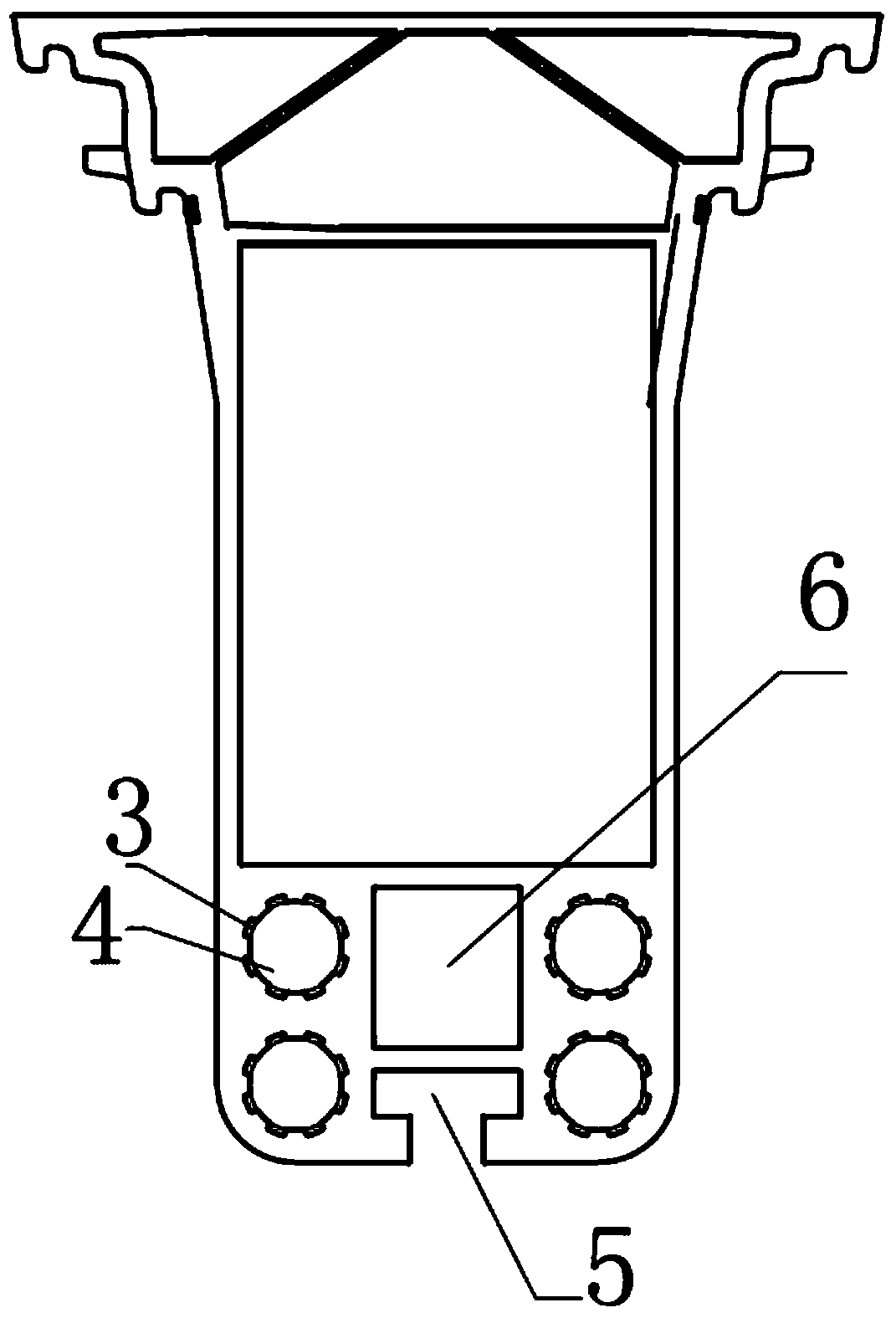

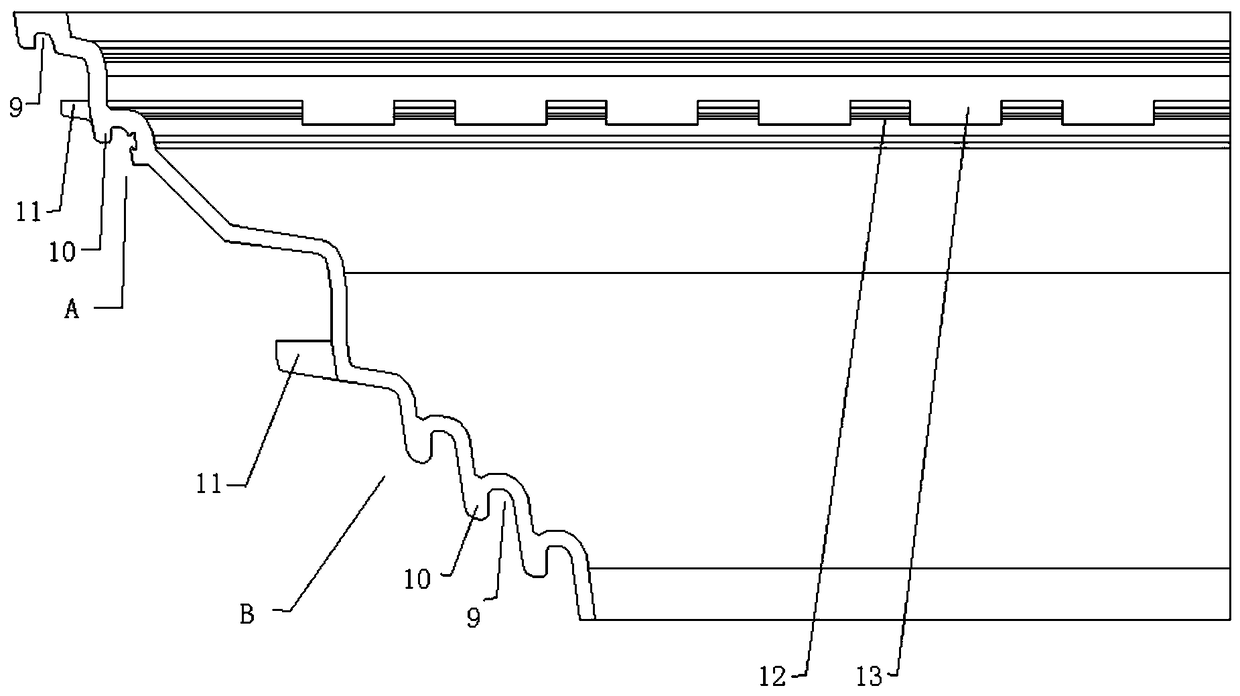

[0063] Such as Figure 1-6 As shown, a load template of this embodiment includes

[0064] The template body 1 has a pouring surface 7, an outer surface opposite to the pouring surface 7, and a connecting edge formed between the pouring surface 7 and the outer surface,

[0065] The outer side of the template body 1 is provided with a beam-shaped supporting body 2, and the supporting body 2 extends from one of the splicing edges of the template body 1 to the other splicing edge opposite to the splicing edge . In this embodiment, the supporting body 2 is a box-shaped structure.

[0066] The above-mentioned solution is the core solution of the present invention. By integrally forming the supporting body 2 on the back of the template body 1, the template has a load-bearing capacity. Using the supporting mechanism can not only achieve rapid turnover, improve the efficiency of cycle use, and save costs, but also because there is no need to set up a supporting structure, the struct...

Embodiment 2

[0083] Such as Figure 7-13 As shown, the difference between this embodiment 2 and embodiment 1 lies in the second connection structure B. In this embodiment 2, the second connection structure B includes the adjacent template molded on the carrier body 2 Three first locking grooves 16 on the butt joint edge of the carrying bracket 2, the cross section of the first locking groove 16 is a shape with a narrow width at the notch and a wide width at the bottom of the groove, and the locking The surface is surrounded by the first locking groove 16 on the two butted supporting brackets 2, the cross-sectional shape of the locking key 8 and the cross-section surrounded by the two first locking grooves 165 The shapes are consistent, and the insertion end of the locking key 8 is set in a wedge shape. Of course, the number of the first locking grooves 16 is not limited to three, and can be set as required.

[0084] Figure 10 yes Figure 9 A simple deformation of , through this deforma...

Embodiment 3

[0086] Such as Figure 14-16 As shown, in this embodiment, the second connection structure B includes a second locking groove 17 and a second locking groove 17 molded on the connecting edge of the carrier body 2 that abuts with the adjacent carrier body 2 . A second locking projection 18, the cross section of the second locking groove 17 is narrow in width at the notch and wide in the bottom of the groove, the second locking groove 17 and the second locking projection 18 is adapted to cooperate with the corresponding second locking projection 18 and second locking groove 17 on the adjacent template. Likewise, the number of the second locking grooves 17 and the number of the second locking projections 18 can also be set according to needs. In order to ensure reliable connection, a wedge-shaped locking block 19 is driven between the second locking groove 17 and the second locking protrusion 18 inserted into the second locking groove 17 .

[0087] Figure 17 yes Figure 16 A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com