Vortex-spun high-count high-density fabric and production method thereof

A high-count, high-density, vortex spinning technology, used in textiles, fabrics, multi-strand fabrics, etc., can solve the problems of unsatisfactory fabric quality, low yield and high textile costs, and achieve good moisture absorption and warmth retention. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

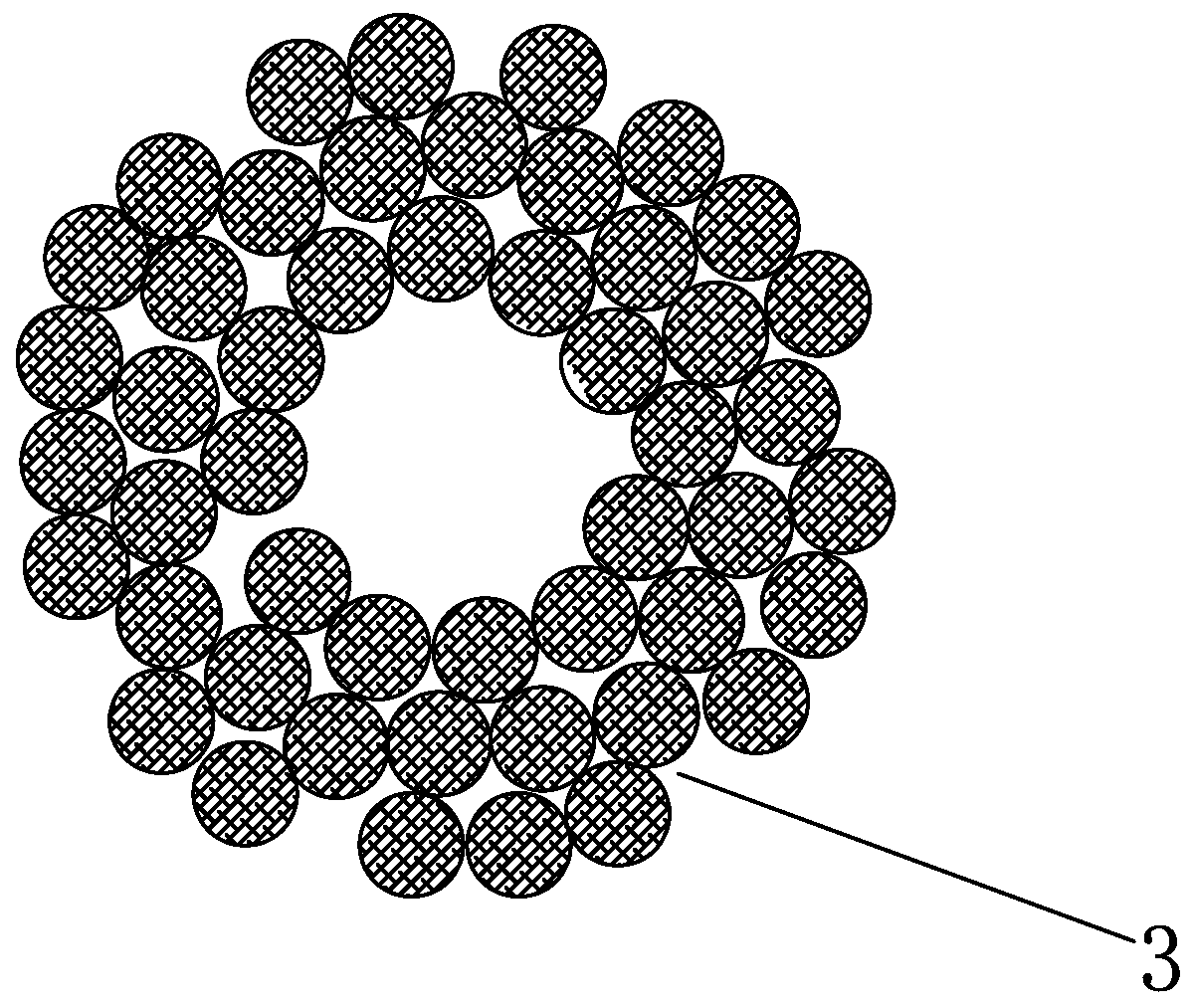

[0025] combine figure 1 with figure 2 , The invention discloses a vortex spinning high-count and high-density fabric. Generally, compared with chemical fibers, cotton fibers have poor clustering properties and low monofilament strength. It is difficult to weave high-count and high-density fabrics, and the yield rate is low. However, cotton fibers have good moisture absorption, breathability and natural skin-friendly properties that chemical fibers do not have. features. In the present invention, the yarn structure is improved and the core-spun yarn is used for weaving to increase the strength of the yarn during the weaving process. After the weaving is completed, the core yarn of the core-spun yarn is hydrolyzed to form a hollow pure cotton yarn. It has better fluffy and soft touch, good warmth retention and strong three-dimensional effect. At the same time, through a reasonable organizational structure, chemical fiber and cotton are organically combined to give full play t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com